High precision punching die

A high-precision, punching technology, applied in the direction of piercing tools, manufacturing tools, metal processing equipment, etc., can solve the problems of easy deformation of metal pipes, lower product qualification rate, and low hole quality, so as to achieve simple structure and low manufacturing cost , the effect of high molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

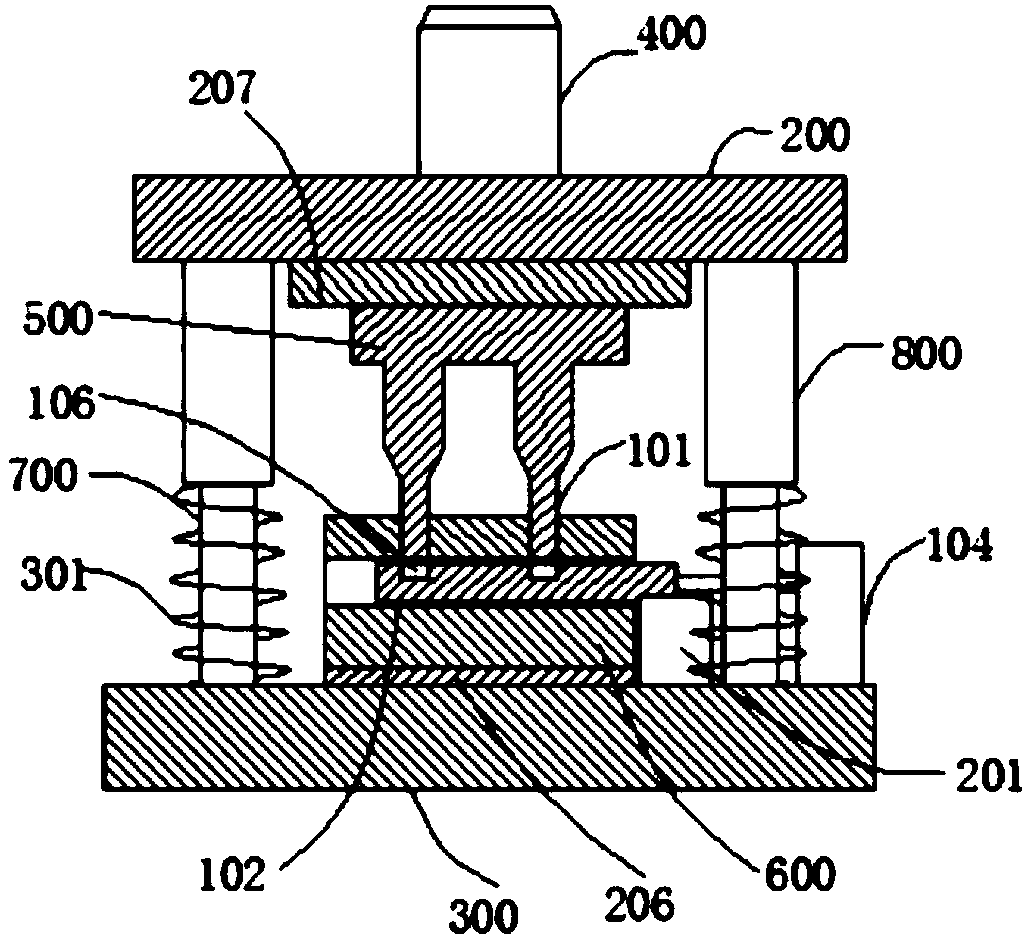

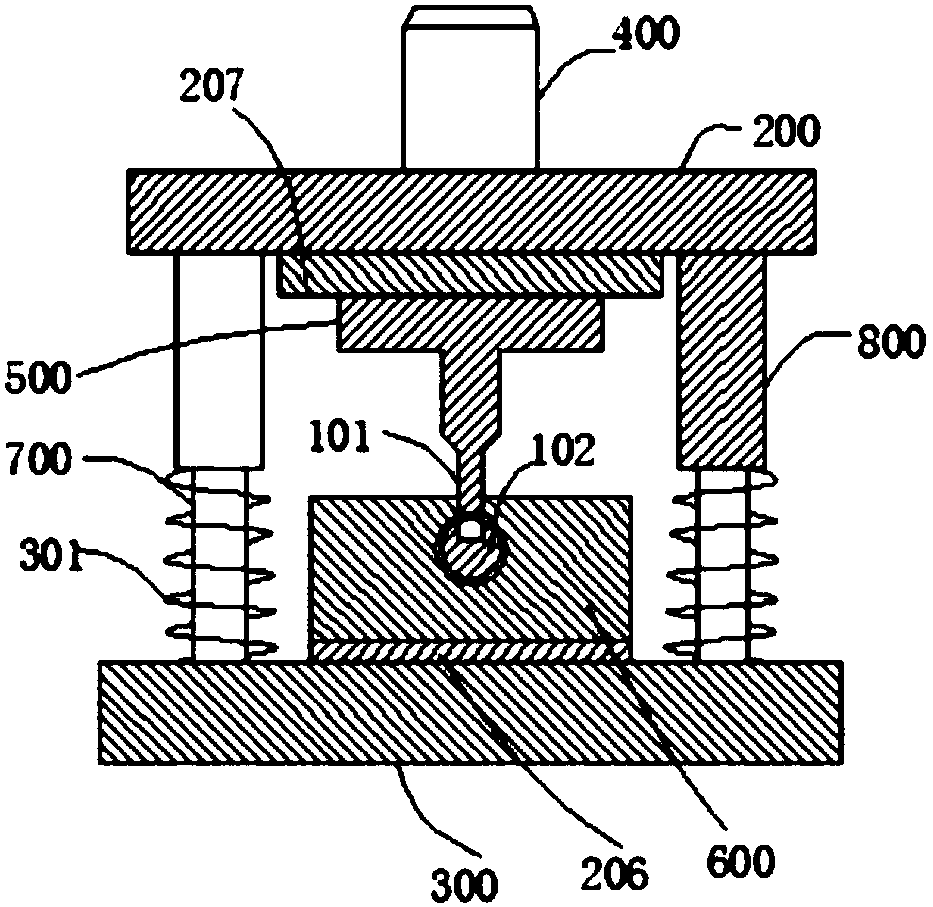

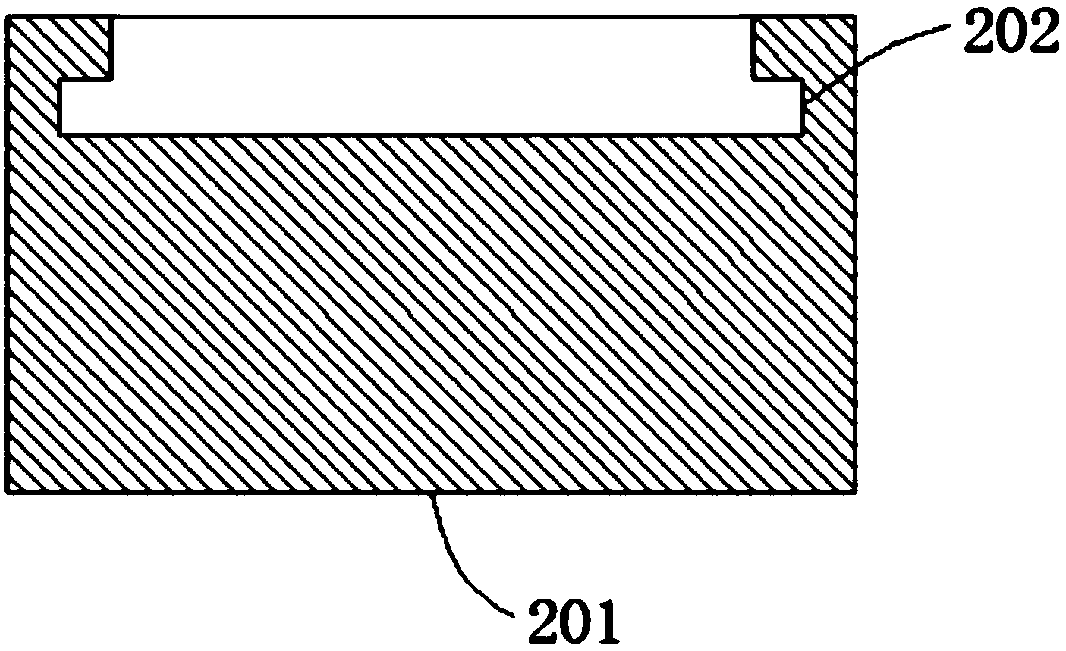

[0029] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0030] Using the punching die for punching can improve productivity, and the product quality is stable and safe, but there are some defects in the existing punching die. The existing punching die has only one punch, and only one hole can be punched at a time. , If multiple continuous holes are punched on the metal pipe, the metal pipe needs to be installed repeatedly, which reduces the production efficiency and increases the installation error, and then the punching accuracy of the hole is low, the qualified rate of the product decreases, and the cost increases.

[0031] In view of this, the designer of the present invention designed a high-precision punching die. When punching, the core-pulling slider is located in the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com