Method for preparing graphene layer on sensor substrate surface

A sensor substrate and graphene layer technology, applied in the field of sensing materials, can solve the problems of low sensitivity and difficult desorption, and achieve the effects of high sensitivity, short desorption time and deep detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

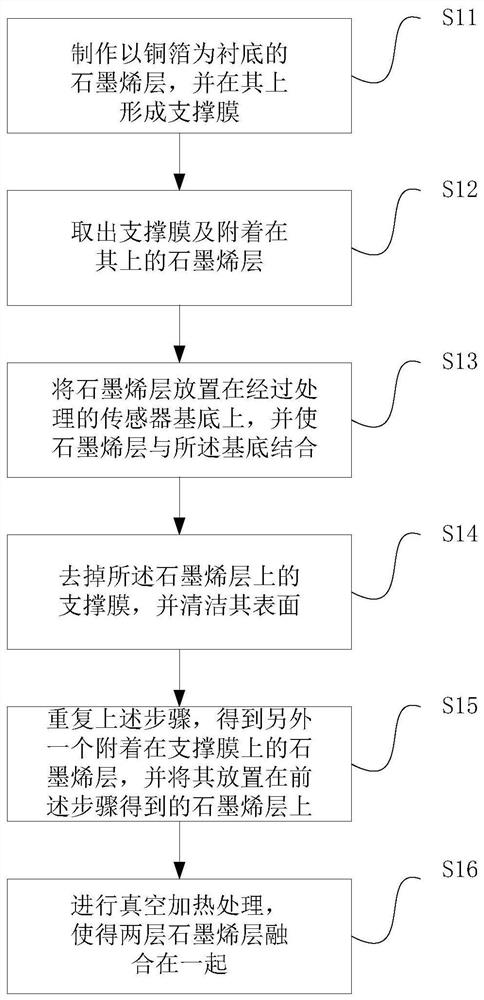

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, in a method embodiment of preparing a graphene layer on the sensor substrate surface of the present invention, the method may further comprise the steps:

[0025] Step S11 makes the graphene layer with copper foil as the substrate, and forms a support film thereon: in this embodiment, the graphene layer obtained at last is thicker than the thickness of the common graphene layer, and adopts this embodiment The sensor whose graphene layer is generated by the method in the middle method has a greatly improved adsorption capacity for some special impurities contained in the air, and at the same time requires a shorter desorption time, which makes the sensor more sensitive. The interval between two measurements is shorter and the efficiency is higher. In terms of the preparation method, in this embodiment, a step-by-step pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com