Offshore fan prefabricated high pile bearing platform foundation structure and installation method

A high-pile cap, prefabricated assembly technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problem of difficult to meet the load requirements of the structure on the foundation, affecting the application and promotion of high-pile cap foundation, design, construction and construction complexity, etc. problems, to achieve the effect of reducing offshore installation costs and on-site construction costs, saving comprehensive costs, and improving production costs and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0031] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is further described.

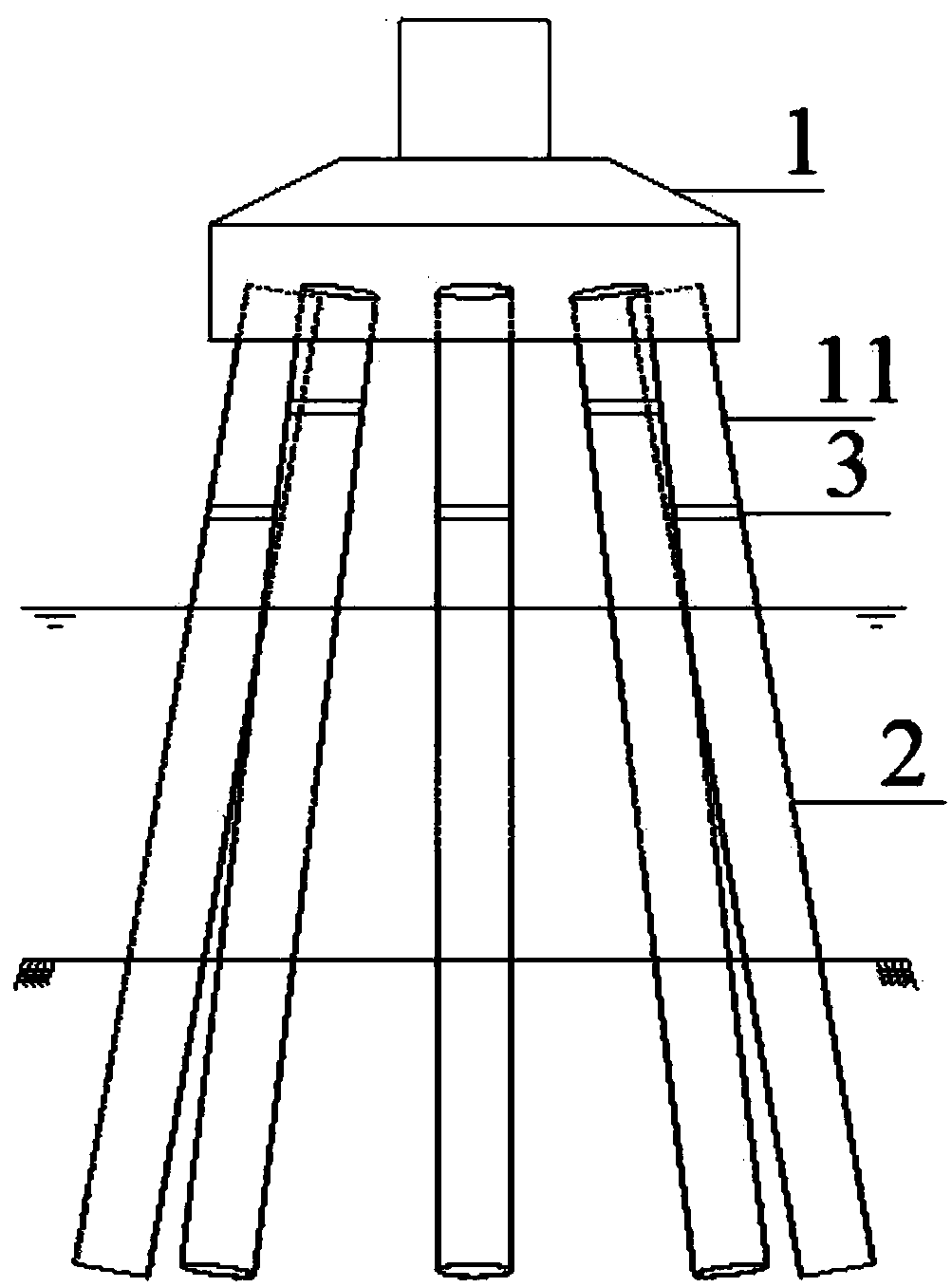

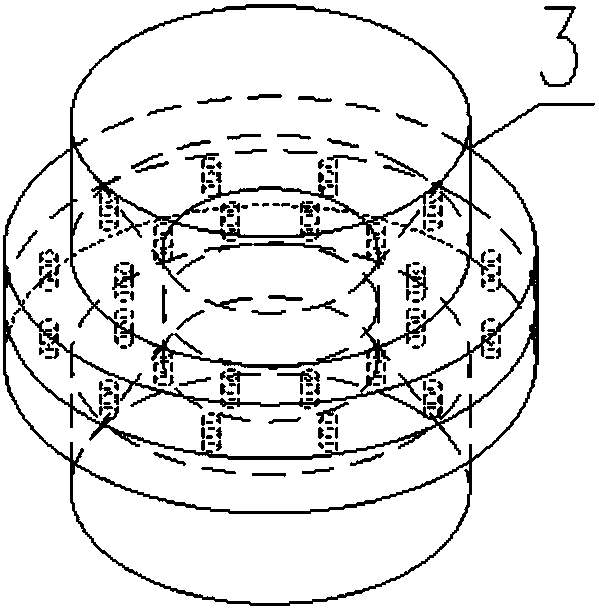

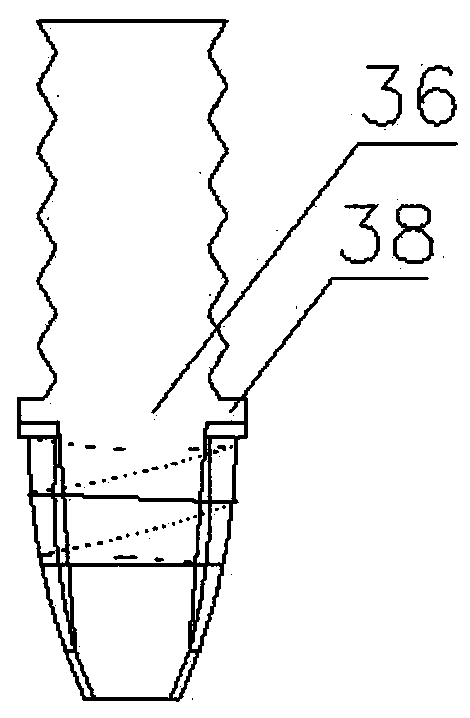

[0032] Such as Figure 1-5 As shown, the present invention provides a prefabricated assembly type high pile cap foundation structure for offshore wind turbines, including a cap structure 1, an upper pipe pile 11, a lower pipe pile 2 and a steel structure node 3; the cap structure 1 consists of a cylindrical The section and the top are formed by a conical transition section of a circular truncated section, the cylindrical section and the conical transition section are integrally formed, and the conical transition section is located above the cylindrical section; the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com