An integrated structure and construction method for existing building exterior wall insulation

It is a technology for external wall insulation and existing buildings, which is applied in the direction of building structure, construction, building maintenance, etc. It can solve the problems that the safety of pasted bricks cannot be guaranteed, the use of external wall insulation is limited, and the fire performance is not good, etc. Anti-shear area, simple construction process, convenient and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

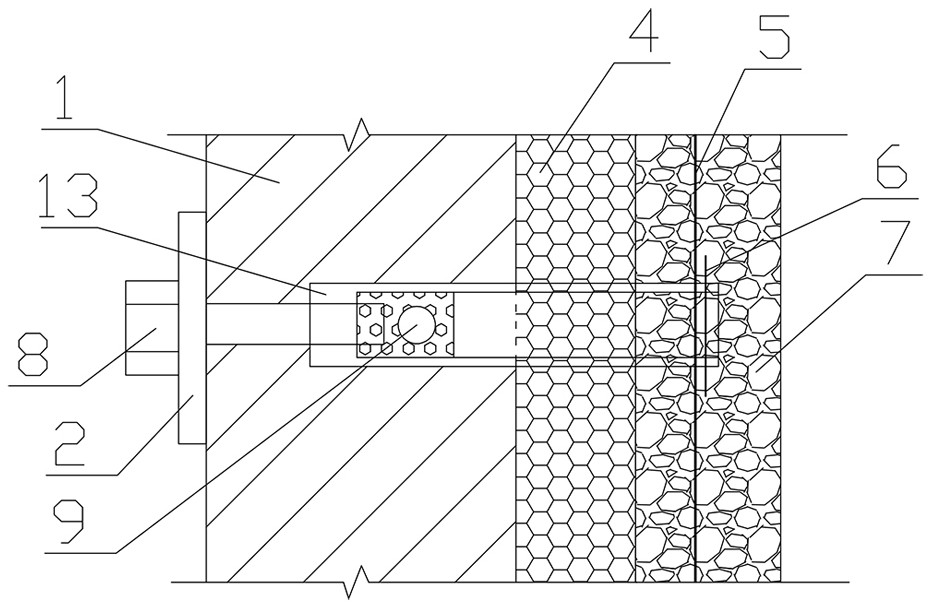

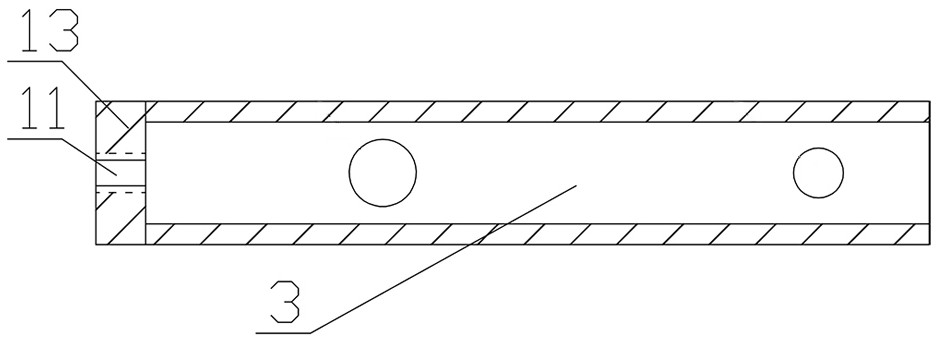

[0034] Embodiment 1: as Figure 1 ~ Figure 3 As shown, an existing building exterior wall thermal insulation integrated structure includes an existing wall 1, a thermal insulation board 4 and a surface layer 7, the inner side of the thermal insulation board 4 is arranged on the outer side of the existing wall 1, and the thermal insulation board 4 The outer side is connected with the surface layer 7, and the interior of the surface layer 7 is longitudinally arranged with a grid-shaped steel mesh 5; the inside of the existing wall 1, the insulation board 4 and the surface layer 7 are all reserved with a first circular circular Holes 9, the two ends of the first circular hole 9 do not exceed the two sides of the existing wall 1 and the surface layer 7, and the connecting pipe 3 is horizontally arranged in the first circular hole 9; the connecting pipe 3 is a circular pipe, one end of the connecting pipe 3 is provided with a sealing plate 13, and the center of the sealing plate 13...

Embodiment 2

[0038] Embodiment 2: as Figure 4 ~ Figure 8 The construction method of the existing building exterior wall insulation integrated structure based on the existing building exterior wall insulation integration structure shown includes the following procedures:

[0039] a) drilling, drilling the first circular hole 9 outside the existing wall 1, the diameter of the first circular hole 9 is transitionally matched with the connecting pipe 3; the first circular hole 9 is close to the existing wall 1 The second circular hole 10 is drilled at the center of one side; during drilling, the first circular hole 9 is not less than 30mm apart from the inner surface of the existing body of wall 1, and the two-way spacing of the first circular hole 9 is not more than 1000mm.

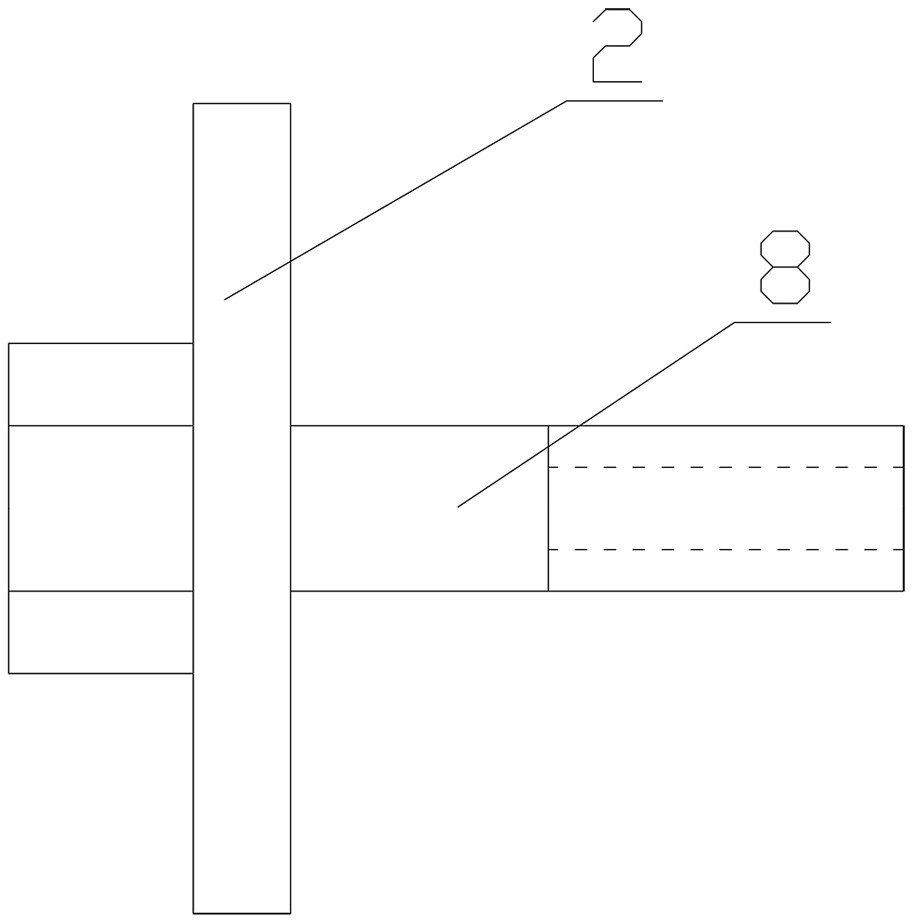

[0040]b) Install the connecting pipe 3 and the pipe seat, insert the connecting pipe 3 into the first circular hole 9 on the existing wall 1, and push it to the bottom of the first circular hole 9; and pass the bolt 8 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com