Wind direction rotary type surface cooler structure for air conditioning refrigeration system

A technology for air-conditioning refrigeration and surface coolers, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as increased energy consumption, low heat exchange efficiency, low heat exchange efficiency, etc. Improved heat exchange efficiency and flexible location settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

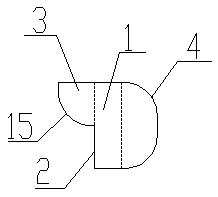

[0027] Embodiment 1. An air-conditioning and refrigeration system uses a wind direction rotary type surface cooler structure, which includes a plate-shaped surface cooler 1, an air guide pipe shell, and the surface cooler includes parallel fronts and backs, between which there is a The gap is the heat exchange air channel, and the air guide tube shell includes air inlet 2, air outlet 3, curved air guide tube 4 and the surface cooler accommodation chamber, and the surface cooler 1 is arranged in the surface cooler accommodation chamber in the air guide tube shell Inside, the surface cooler 1 is connected to the air guide pipe shell, and after the two are connected, a closed passage with only the air inlet 5 and the air outlet 6 is formed. The heat exchange air passage of the surface cooler is divided into an air inlet section, a return air section, In the air outlet section, the air flow passes through the air inlet, the air inlet section, the curved air duct, the air return sec...

Embodiment 2

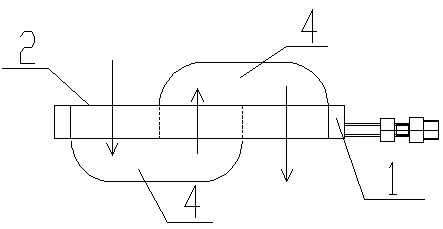

[0035] Example 2, such as figure 2 As shown in the figure, an air-conditioning and refrigeration system uses a wind direction rotary surface cooler structure, which includes a plate-shaped surface cooler 1 and an air guide pipe shell. The surface cooler includes a parallel front and back, and a gap is arranged between the front and back For the heat exchange air passage, the air guide tube shell includes air inlet 2, air outlet 3, curved air guide tube 4 and the surface cooler accommodation cavity, and the surface cooler 1 is arranged in the surface cooler accommodation cavity in the air guide tube shell , the surface cooler 1 is connected to the air guide pipe shell, and after the two are connected, a closed passage with only the air inlet 5 and the air outlet 6 is formed. The heat exchange air passage of the surface cooler is divided into an air inlet section, a return air section, and an air outlet section In the wind section, the wind flow passes through the air inlet, th...

Embodiment 3

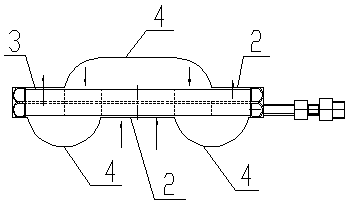

[0040] Embodiment 3, an air-conditioning and refrigeration system with a wind direction rotary surface cooler structure, differs from Embodiment 2 in that the long plate-shaped heat exchange air duct is divided into five sections, and the air inlet section in the middle corresponds to an air inlet 2. The other side of the surface cooler facing the air inlet is provided with a long D-shaped heat exchange air duct, and the air flows separately to the two sides, each passing through a return air section and an air outlet section, and exits from the air outlets on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com