Heating furnace variable alternate acknowledge overall planning and limit control method

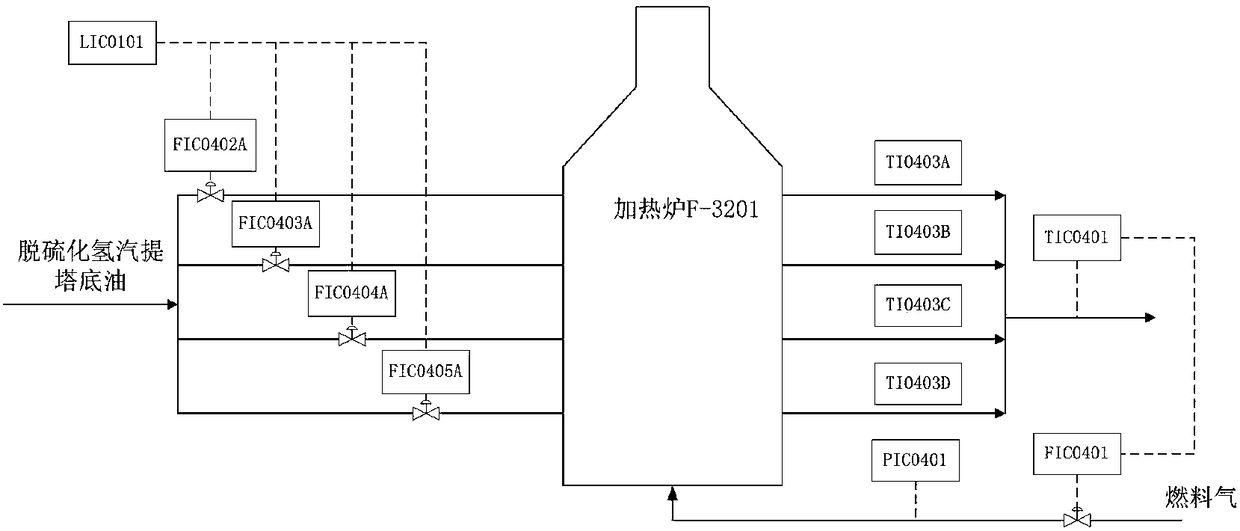

A technology of interactive response and control method, which is applied in the direction of furnace control devices, lighting and heating equipment, furnaces, etc., can solve problems such as unstable operation of heating furnaces, coupling of feeding materials to branch furnace tubes, and difficulty in realizing interactive optimal control, etc., to achieve Achieve safe long-term stable operation and solve the effect of large temperature difference in branch circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

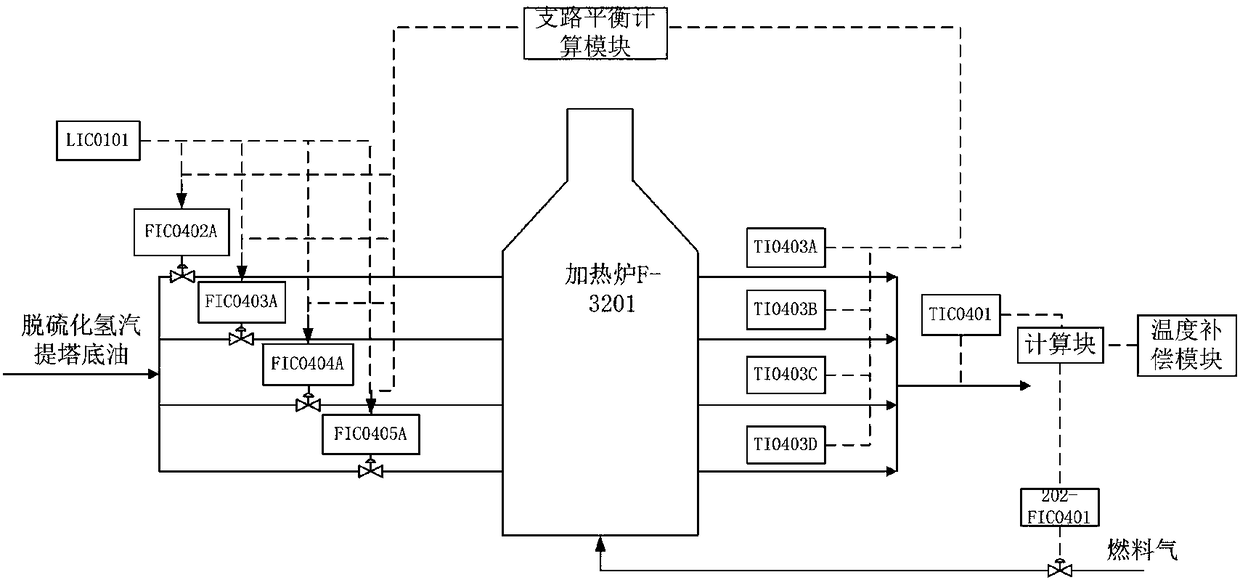

[0028] Such as figure 2 As shown, the control scheme of the heating furnace is optimized. The new control scheme introduces the combustion system and the branch temperature balance system. The combustion system is the basis for the operation of the branch balance and coordinated control system. The temperature balance of the branch circuit works, and the priority of the combustion system is higher than that of the branch circuit temperature balance system. details as follows:

[0029] (1) Increase the branch balance control, according to the temperature difference of the four outlets TI0403A, TI0403B, TI0403C, TI0403D, introduce feedforward control, and fine-tune the maximum temperature feed amount and the minimum temperature feed amount in advance, which is conducive to the stability of the outlet temperature of the heating furnace , and reduce the "bias flow" phenomenon of the four branch flow valves.

[0030] (2) Add a temperature compensation module, which can be put in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com