Calibration method of pump station information intelligent monitoring terminal based on multi-parameter detection

An intelligent monitoring and multi-parameter technology, applied in the direction of measuring devices, testing/calibrating devices, testing/calibrating volume flow, etc., can solve the problems of low measurement accuracy, low accuracy, and low flow measurement accuracy, and achieve good mutual Changeability and scalability, improve the degree of integration, and monitor the effect of comprehensive information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Below in conjunction with accompanying drawing of description, the present invention will be further described.

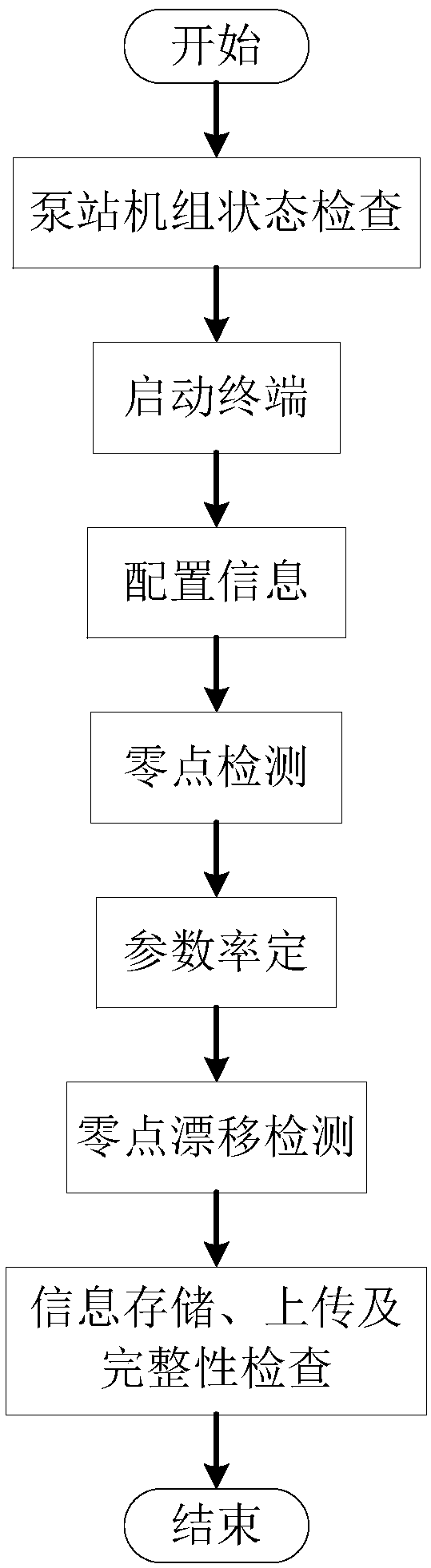

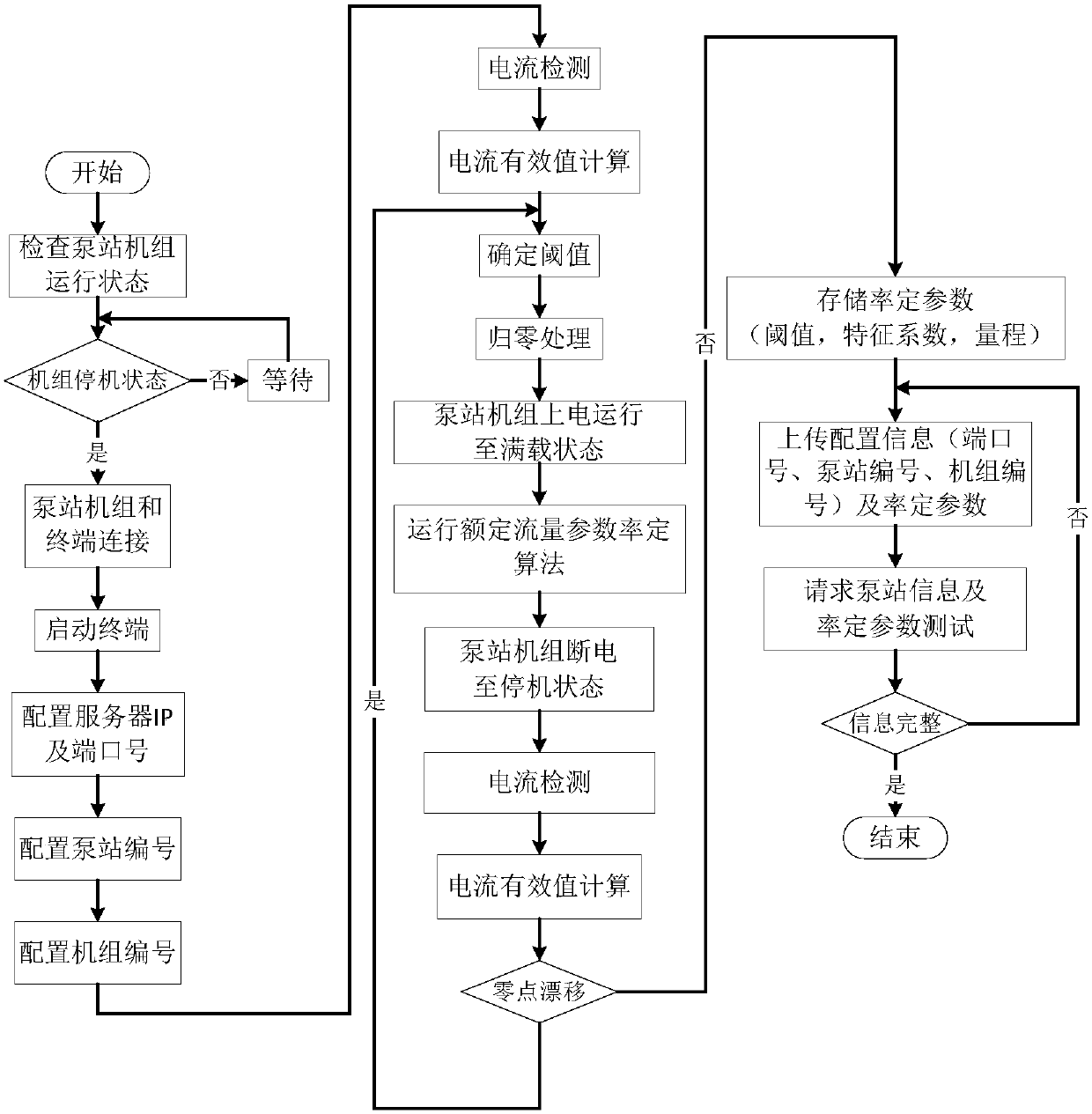

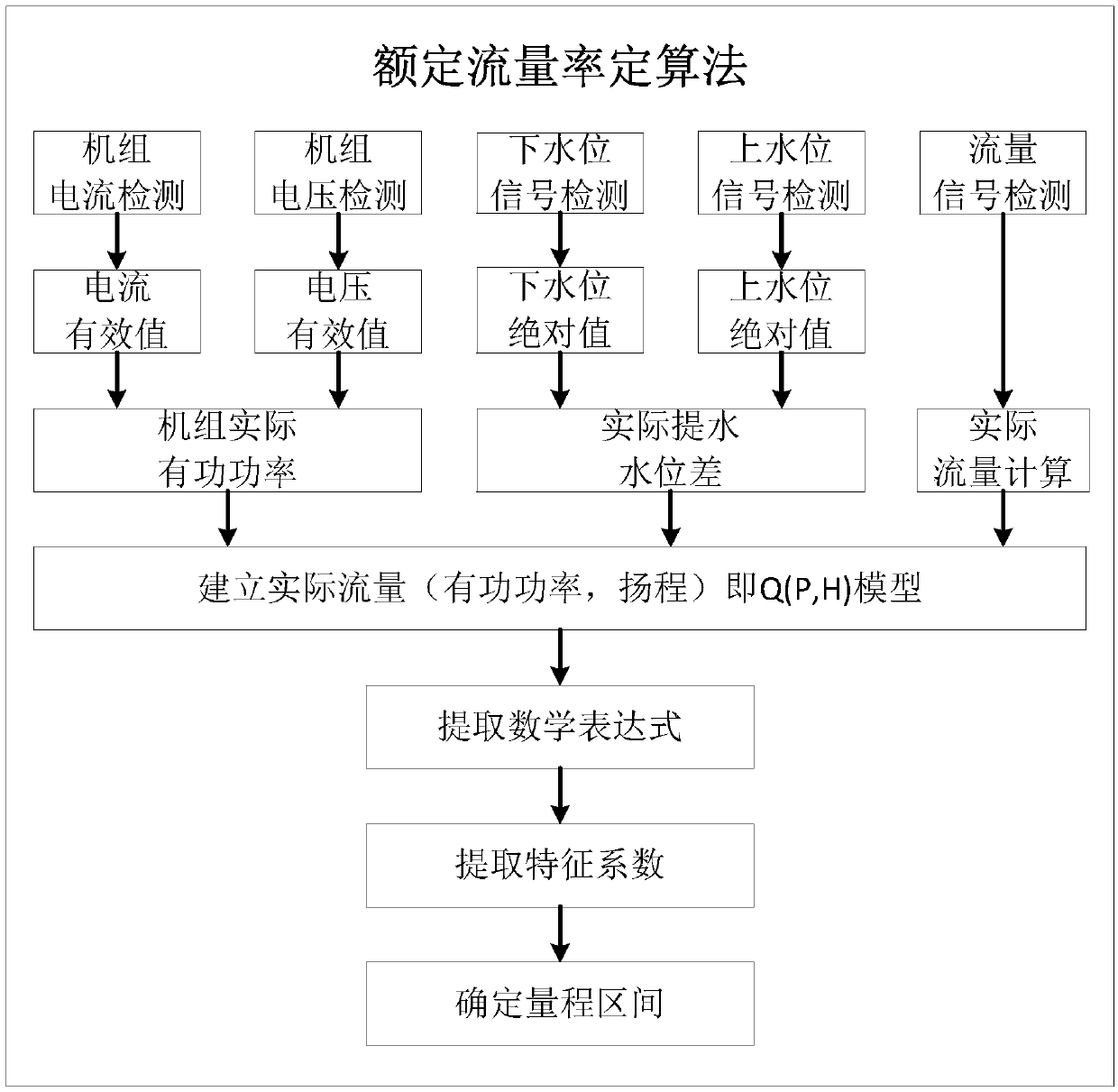

[0068] Such as figure 1 and figure 2 As shown, the present invention provides a method for calibrating a pumping station information intelligent monitoring terminal based on multi-parameter detection, including the following steps:

[0069] 1) Check the status of the pumping station unit and make sure that the pumping station unit is in a shutdown state;

[0070] 2) Power on the pumping station information intelligent monitoring terminal, start the pumping station information intelligent monitoring terminal, and complete the initialization;

[0071] 3) Perform information configuration on the pumping station information intelligent monitoring terminal;

[0072] 4) The intelligent monitoring terminal of the pumping station information performs zero point detection to determine whether there is leakage current in the pumping station unit in the shutdown st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com