Acid corrosion crack etching morphology and flow conductivity testing method

A technology of etching morphology and testing method, applied in measurement devices, analysis of suspensions and porous materials, instruments, etc., can solve the changing process of the conductivity of tensile acid etching cracks that cannot be well simulated, and the representativeness of simulation experiments Not strong and other problems, to achieve the effect of improving the effect of acid pressure transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

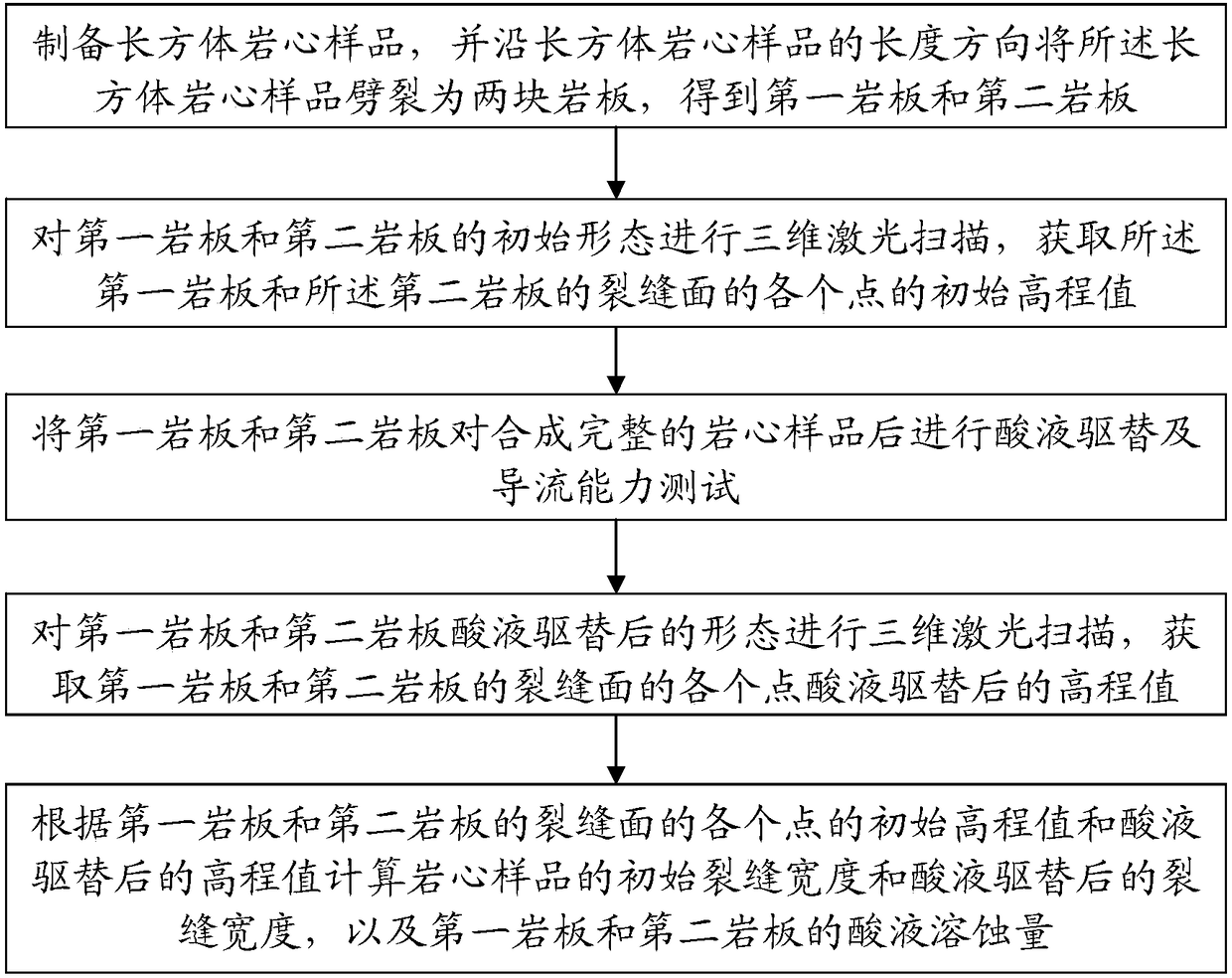

[0048] This embodiment provides a method for testing the etching morphology and conductivity of acid-etched cracks, see figure 1 , the method includes the following steps:

[0049] Step 101, preparing a cuboid core sample, and splitting the cuboid core sample into two rock slabs along the length direction of the cuboid core sample to obtain a first rock slab and a second rock slab.

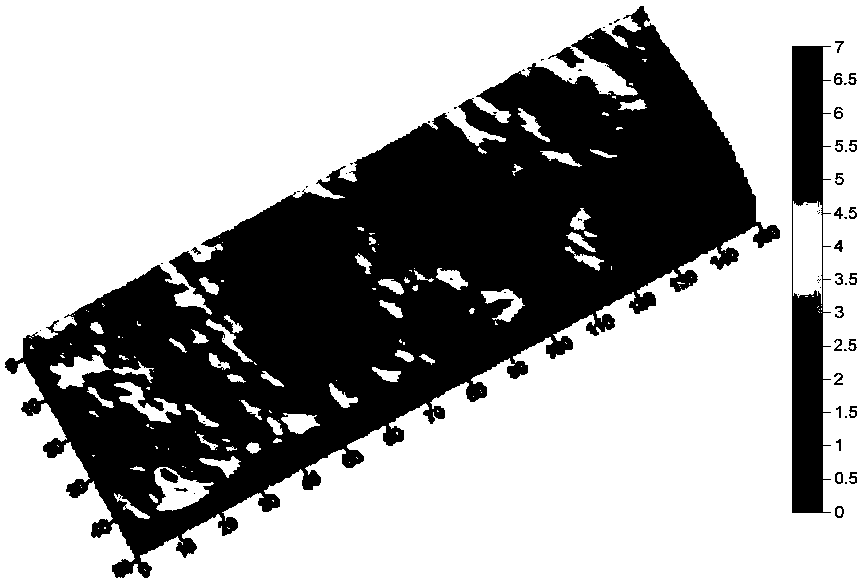

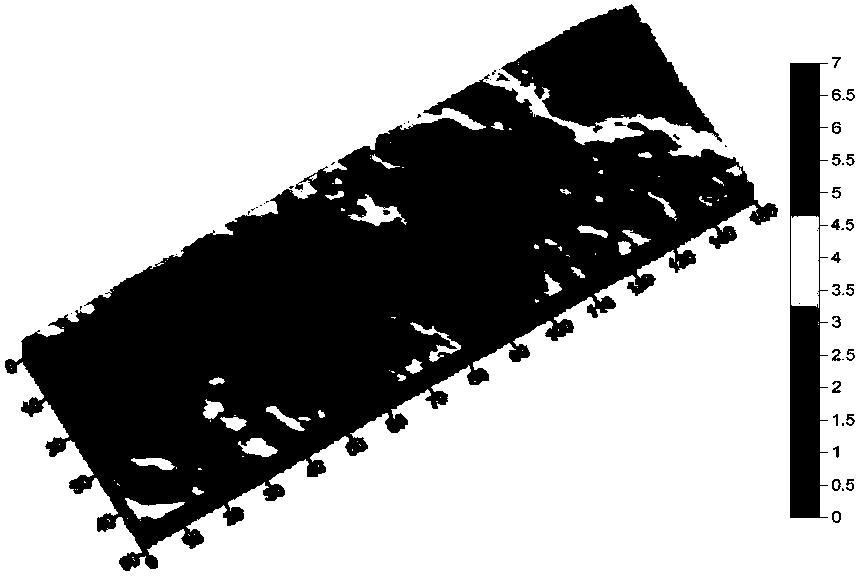

[0050] Step 102, perform three-dimensional laser scanning on the initial shape of the first rock slab and the second rock slab, and obtain the initial elevation values of each point on the fracture surface of the first rock slab and the second rock slab.

[0051] In step 103, the first rock plate and the second rock plate are combined to form a complete core sample, and then the acid displacement and conductivity tests are performed.

[0052] In step 104, three-dimensional laser scanning is performed on the morphology of the first slab and the second slate after acid liquid displacement, and th...

Embodiment 2

[0056] This embodiment provides a method that can quantitatively characterize the relationship between the acid-rock heterogeneous etching form and the conductivity of acid-etched fractures, and can truly simulate the conductivity of tensional acid-etched fractures formed during the actual on-site acid fracturing construction process. The test method of acid-etched crack etching morphology and conductivity during the change process, see figure 1 , including the following steps:

[0057] Step 201, preparing a cuboid core sample, and splitting the cuboid core sample into two rock slabs along the length direction of the cuboid core sample to obtain a first rock slab and a second rock slab.

[0058] The cuboid core sample is obtained by cutting and grinding the full-diameter core, and the six faces of the obtained cuboid core sample should be smooth and flat. Those skilled in the art can understand that the full-diameter cores are collected from formations that need to be tested ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com