Experimental test method for effective length of acid etching crack

A test method and technology of effective length, applied in the field of oil and gas reservoir exploration and development, can solve the problems of small size, inability to simulate the formation process of extensional acid corrosion fractures well, and the representativeness of simulation experiments is not strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

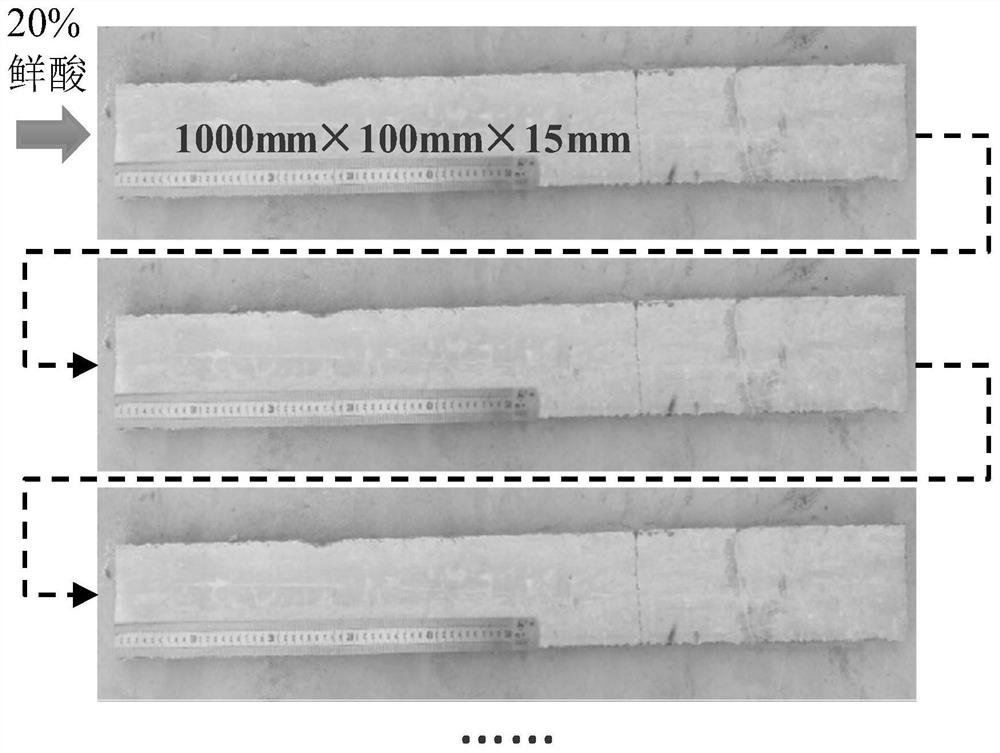

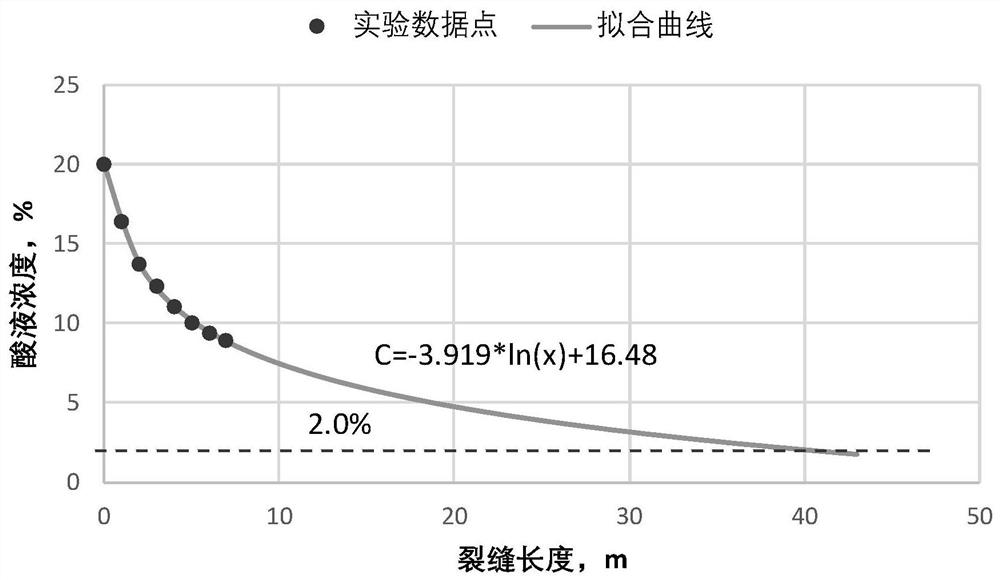

[0042] This embodiment provides an experimental test method for the effective length of acid-etched fractures. The method is used to measure the length of the acid-etched fractures of the acid-etched acid system with a mass concentration of 20% during acid fracturing in dolomite reservoirs. The method includes:

[0043] Step 101, prepare the acid solution: calculate the required 31% industrial hydrochloric acid and the dosage of each additive according to the acid solution formula, and add 31% industrial hydrochloric acid and each additive in order according to the acid solution configuration requirements, and configure the required volume of acid solution; specifically Word:

[0044] This embodiment adopts 20% diverting acid system (the formula is 20% HCl+6% diverting agent+2% corrosion inhibitor+1% corrosion inhibition synergist+2% iron ion stabilizer+0.05% high temperature stabilizer), the preparation 1m 3 This diverting acid needs 709.7kg of 31% industrial hydrochloric ac...

Embodiment 2

[0071] This embodiment provides an experimental test method for the effective length of acid-etched fractures. The method is used to measure the length of the acid-etched fractures of the acid-etched acid system with a mass concentration of 20% during acid fracturing in dolomite reservoirs. The method includes:

[0072] Step 101, prepare the acid solution: calculate the required 31% industrial hydrochloric acid and the dosage of each additive according to the acid solution formula, and add 31% industrial hydrochloric acid and each additive in order according to the acid solution configuration requirements, and configure the required volume of acid solution; specifically Word:

[0073] This embodiment adopts 20% diverting acid system (the formula is 20% HCl+6% diverting agent+2% corrosion inhibitor+1% corrosion inhibition synergist+2% iron ion stabilizer+0.05% high temperature stabilizer), the preparation 1m 3 This diverting acid needs 709.7kg of 31% industrial hydrochloric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com