High-temperature-resistant clean acidic fracturing fluid and preparation method thereof

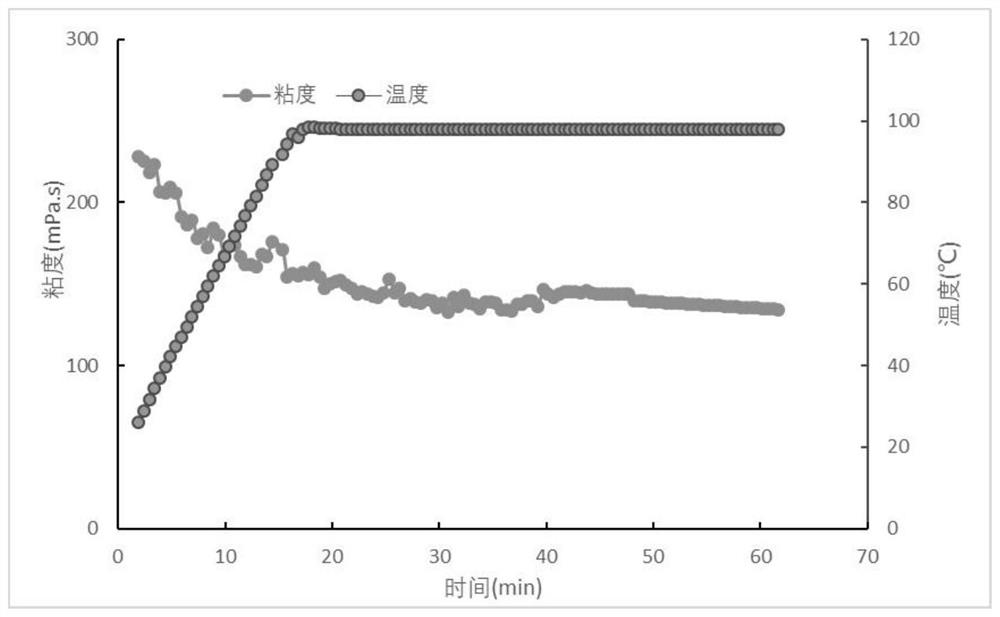

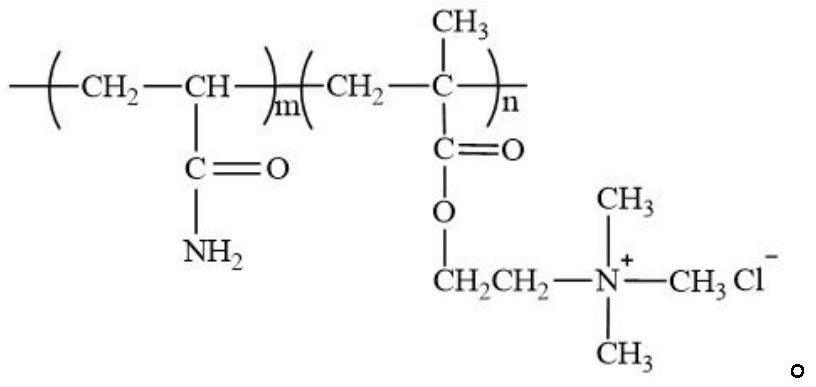

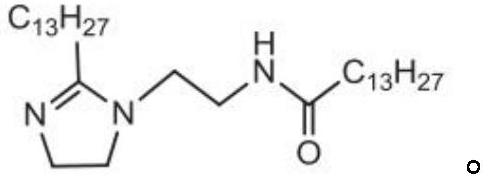

A technology of fracturing fluid and high temperature resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problem that surfactants are not resistant to high temperature (not exceeding 90°C, unstable water-in-oil emulsion, and unstable foam) to achieve the effects of increasing oil recovery, reducing the reaction rate of acid rock, and improving the effect of acid fracturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 82.98g of deionized water into the acid-resistant liquid mixing tank, and gradually add 8.82g of 34% hydrochloric acid (the effective mass concentration is 3%) under the state of stirring. After all the hydrochloric acid is added, stir for 30s; add 4.5g of acetic acid, wait After all the acetic acid is added, stir for 30s; add 1g citric acid and 1g oxalic acid in sequence until they are all dissolved; add 0.3g of viscoelastic surfactant ves-c until they are all dissolved; add 1g of anti-swelling agent JSH until they are all dissolved; add slow Add 0.4 g of etchant until it is completely dissolved. That is, the target high temperature resistant acidic clean fracturing fluid.

Embodiment 2

[0038]Add 79.54g of deionized water into the acid-resistant liquid mixing tank, and gradually add 11.76g of 34% hydrochloric acid (the effective mass concentration is 4%) under the state of stirring. After all the hydrochloric acid is added, stir for 30s; After adding all the ingredients, stir for 30 seconds; add 1g citric acid and 0.5g oxalic acid in sequence until they are all dissolved; add 0.4g of viscoelastic surfactant ves-c until they are all dissolved; add 1.3g of anti-swelling agent JSH until they are all dissolved; add Corrosion inhibitor 0.5g, until all dissolved. That is, the target high temperature resistant acidic clean fracturing fluid.

Embodiment 3

[0040] Add 82.08g of deionized water into the acid-resistant liquid mixing tank, and gradually add 8.82g of 34% hydrochloric acid (the effective mass concentration is 3%) under stirring, and stir for 30s after all the hydrochloric acid is added; add 5g of acetic acid, and wait for the acetic acid After adding all the ingredients, stir for 30 seconds; add 0.8g citric acid and 0.8g oxalic acid in turn until they are all dissolved; add 0.5g of viscoelastic surfactant ves-c until they are all dissolved; add 1.5g of anti-swelling agent JSH until they are all dissolved; Add 0.5 g of corrosion inhibitor until it is completely dissolved. That is, the target high temperature resistant acidic clean fracturing fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com