A model-free adaptive control system and method for blast furnace multi-element molten iron quality

A model-free self-adaptive, hot metal technology, applied in the direction of self-adaptive control, general control system, control/regulation system, etc., can solve the problem that the offline model cannot fully reflect the dynamics of the blast furnace, cannot meet the production process control requirements, and the computational complexity of the data model Large and other problems, to achieve the effects of strong real-time performance, cost saving, and strong resistance to external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

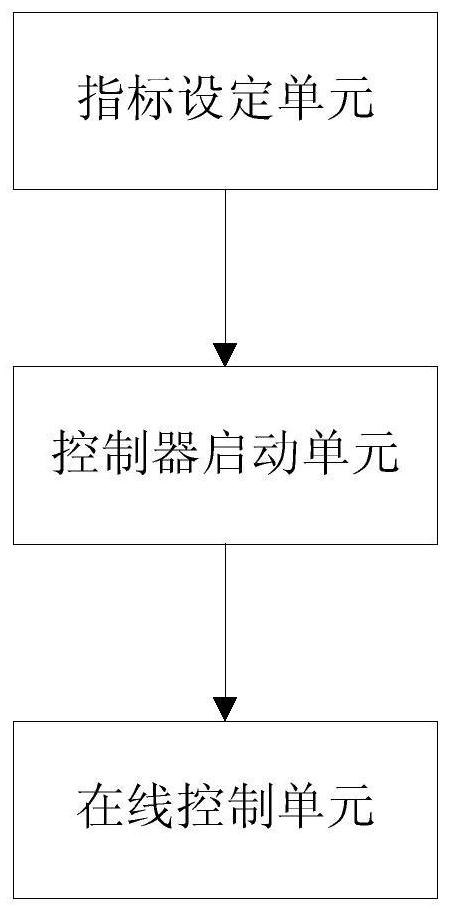

[0060] This embodiment provides a model-free adaptive control system for the quality of multi-element molten iron in a blast furnace, such as figure 1 shown, including:

[0061] Index setting unit: set the expected value of the multi-element molten iron quality index of the blast furnace;

[0062] Also includes:

[0063] Controller start-up unit: Obtain the parameter variables of the blast furnace body production conditions at several historical moments required for model-free adaptive controller parameter correction and the measured values of multivariate molten iron quality indicators at corresponding times. The initial value of the partial derivative is corrected offline;

[0064] On-line control unit: Use the model-free adaptive controller to online control the molten iron quality index to track the expected value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com