Structure of high-precision reflector antenna composite panel and adjustment method thereof

A technology of antenna combination and reflective surface, which is applied in the direction of antennas and electrical components, can solve the problems of poor alignment of rigid connection standard parts, low efficiency, inability to coordinate the linkage of combined panel components, high-precision adjustment, etc., to eliminate Curved, good neutrality, and the effect of improving adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

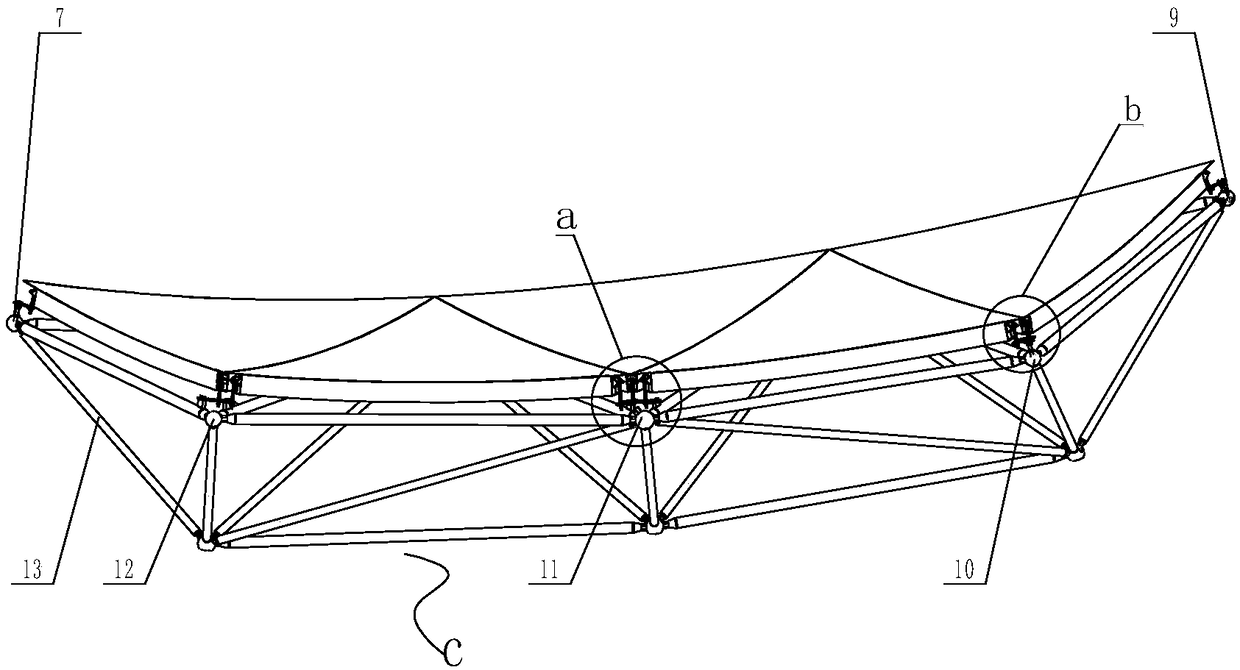

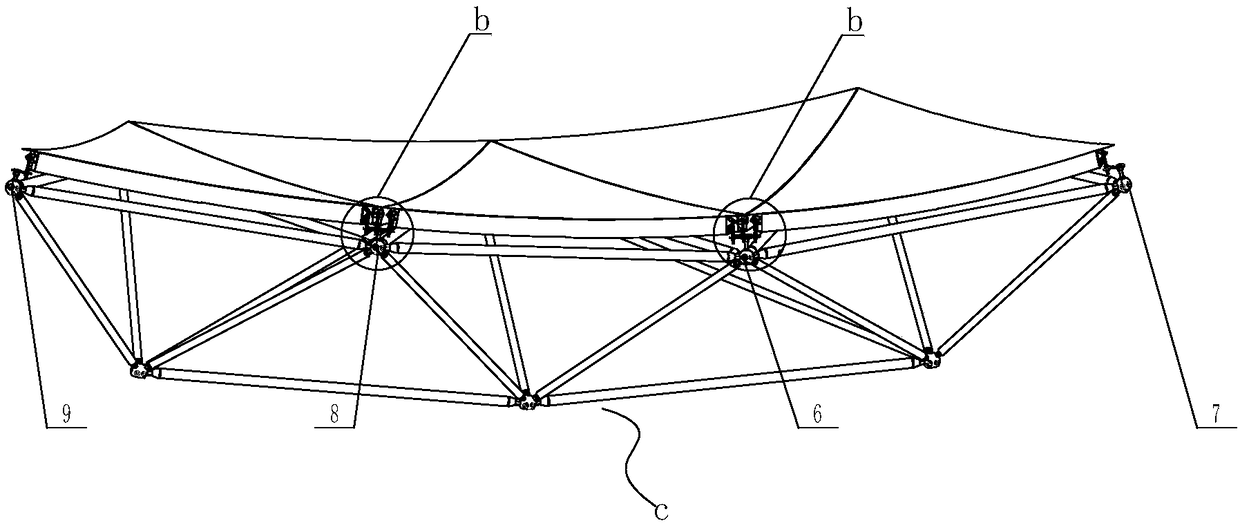

[0041] Embodiment 1, as shown in the figure, the best embodiment of the present invention takes the reflector unit at the edge of the square kilometer array antenna SKA as an example, as figure 1 shown, figure 1It is a schematic diagram of the overall installation structure of the antenna.

[0042] The present invention provides a structure of a high-precision reflector antenna composite panel, including a back frame for supporting a high-precision reflector antenna, and a plurality of panel assemblies 15 are connected to the back frame, and the back frame is composed of a plurality of pull rods Combined to form, the connection points of the tie rods are all supported by bolt balls at all angles. The above-mentioned multiple panel assemblies 15 form a high-precision reflective surface. There are multiple multi-panel panels for adjusting the posture of the panel assembly 15 on the antenna back frame c. Level adjustment unit, each panel assembly 15 and adjacent panel assembly 1...

Embodiment 2

[0044] Embodiment 2 provides a method for adjusting a high-precision reflector antenna combination panel, including the following steps: Please add corresponding numbers to all the corresponding components in the manual, and finally check

[0045] S1: Design and manufacture displacement adjustment unit b:

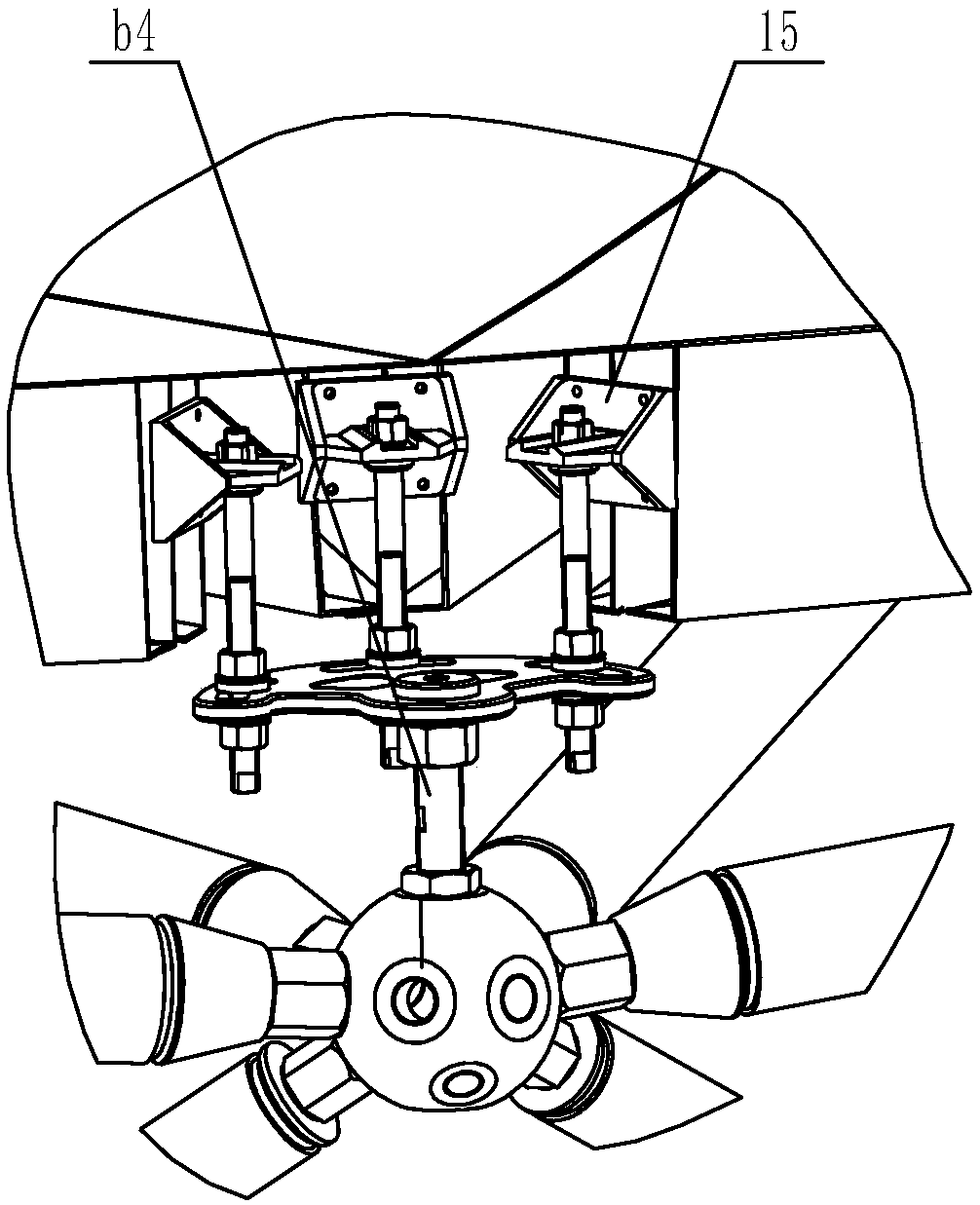

[0046] The displacement adjustment unit b includes a coarse displacement adjustment screw b4, a coarse displacement adjustment disc b2, and a fine displacement adjustment screw b3, the coarse adjustment screw b4 is screwed to the back frame, and the coarse displacement adjustment disc b2 is screwed to the coarse On the adjustment screw b4, the displacement coarse adjustment disc b2 is provided with a plurality of slots corresponding to the panel assembly 15 one by one, and each slot is movably connected with a displacement fine adjustment screw b3, and the displacement fine adjustment screw b3 is connected to the panel The components 15 are fixedly connected in one-to-one c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com