A coaxial high-speed direct-drive helicopter and its flight control method

A helicopter and high-speed technology, applied in the field of aircraft, can solve the problems of complex transmission mechanism, small differential control angle, low reliability and driving efficiency, etc., and achieve the effects of improving system efficiency, reducing system mass, and small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

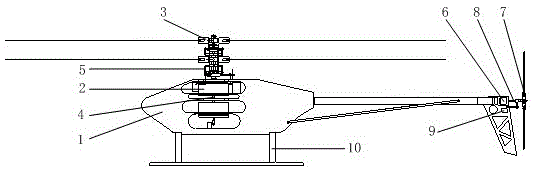

[0030] Such as figure 1Shown is a schematic diagram of the overall structure of a coaxial high-speed direct-drive helicopter disclosed in this embodiment. Disclosed in this embodiment; the coaxial high-speed direct-drive helicopter mainly includes a frame 1, a main rotor engine 2, a main rotor component 3, a main rotor drive shaft 4, a main rotor pitch adjustment component 5, a tail rotor engine 6, and a propulsion tail rotor Part 7, tail rotor drive shaft 8, tail rotor pitch adjustment part 9 and landing gear 10.

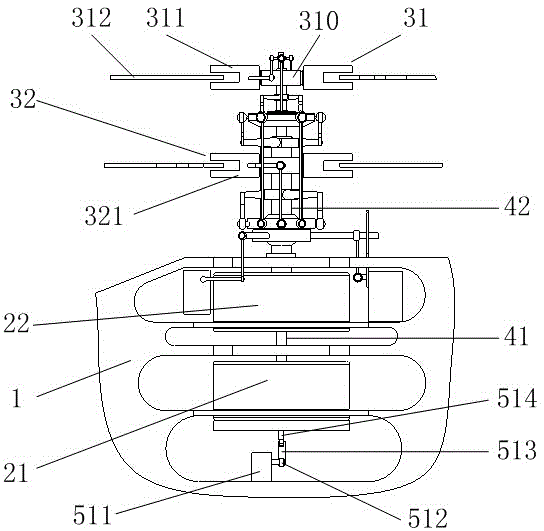

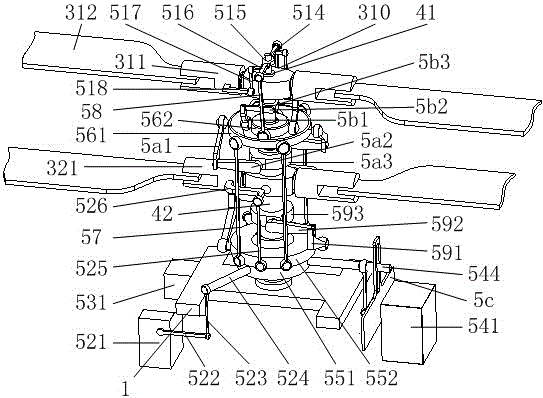

[0031] Such as figure 2 Shown is a schematic diagram of the main rotor drive system and pitch adjustment components of a coaxial high-speed direct-drive helicopter disclosed in this embodiment. Wherein, the main rotor engine 2 is fixedly arranged on the frame 1 . The output shaft of the main rotor engine 2 is fixedly connected with the main rotor transmission shaft 4 to drive the main rotor transmission shaft 4 to rotate, and the main rotor transmission shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com