A making process for heating clothes

A production process and clothing technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of bulky clothing, uncomfortable wearer, unfavorable appearance, etc., and achieve the effect of obvious effect, not easy to fall off, and high comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper", "lower", "bottom" and "top" used in the following description refer to the Directions, the words "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

[0052] Before introducing the manufacturing process of heated clothes, first explain the heated clothes:

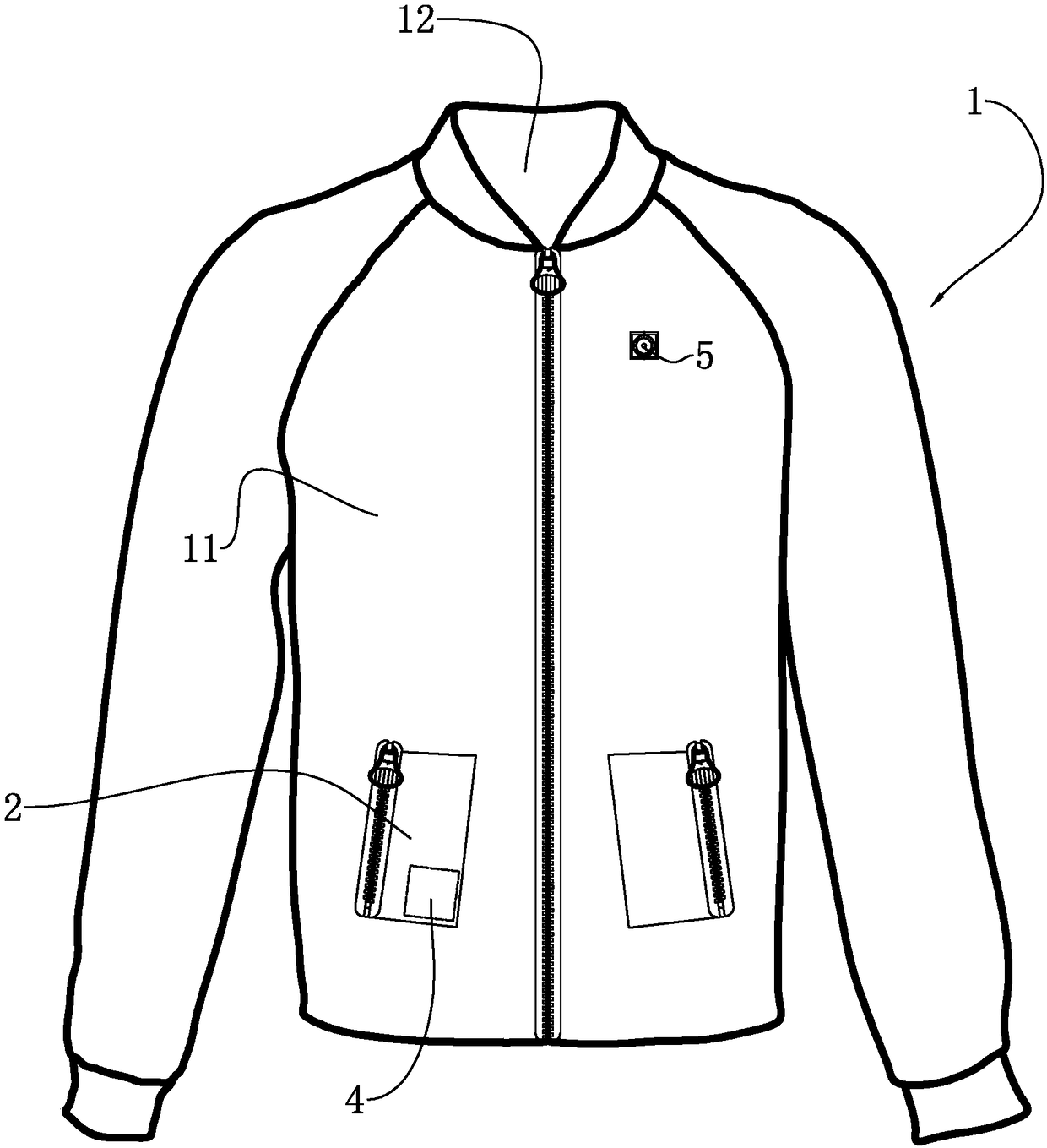

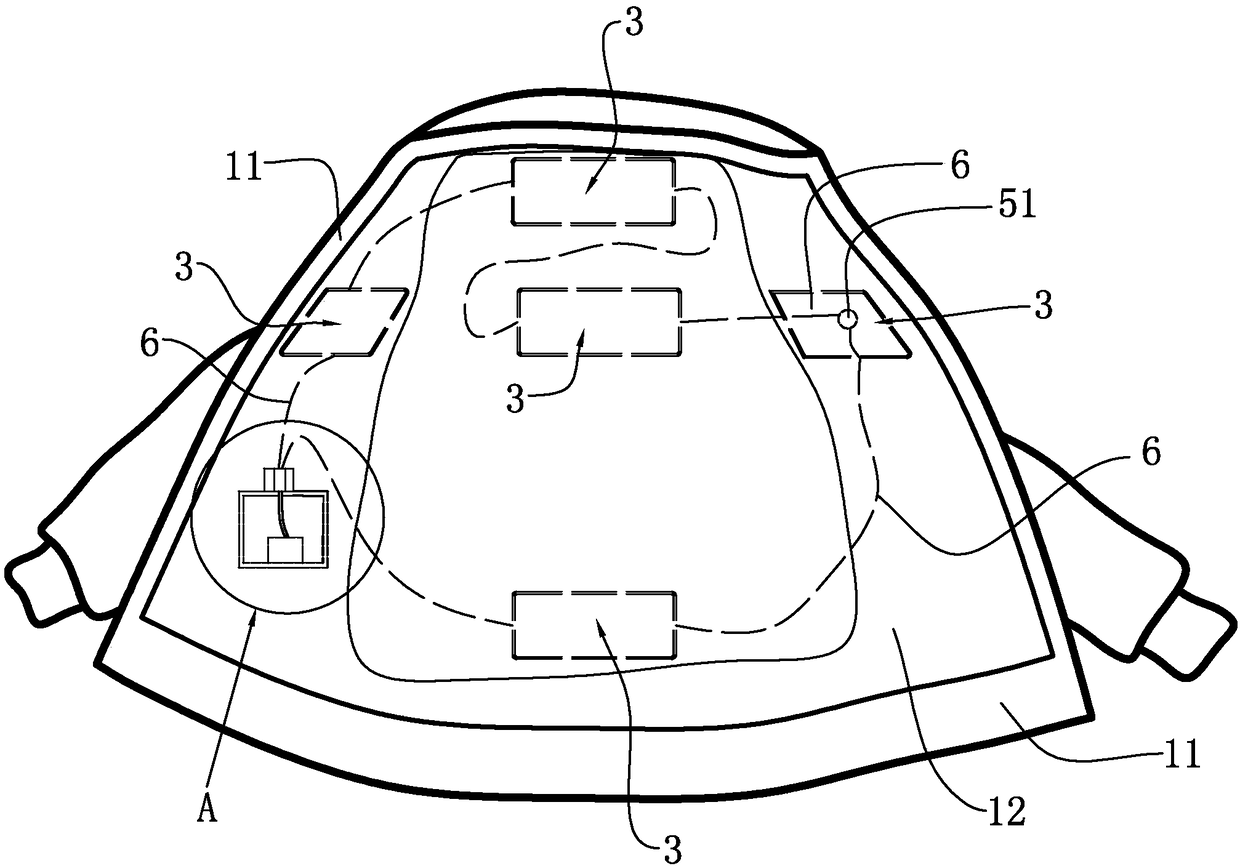

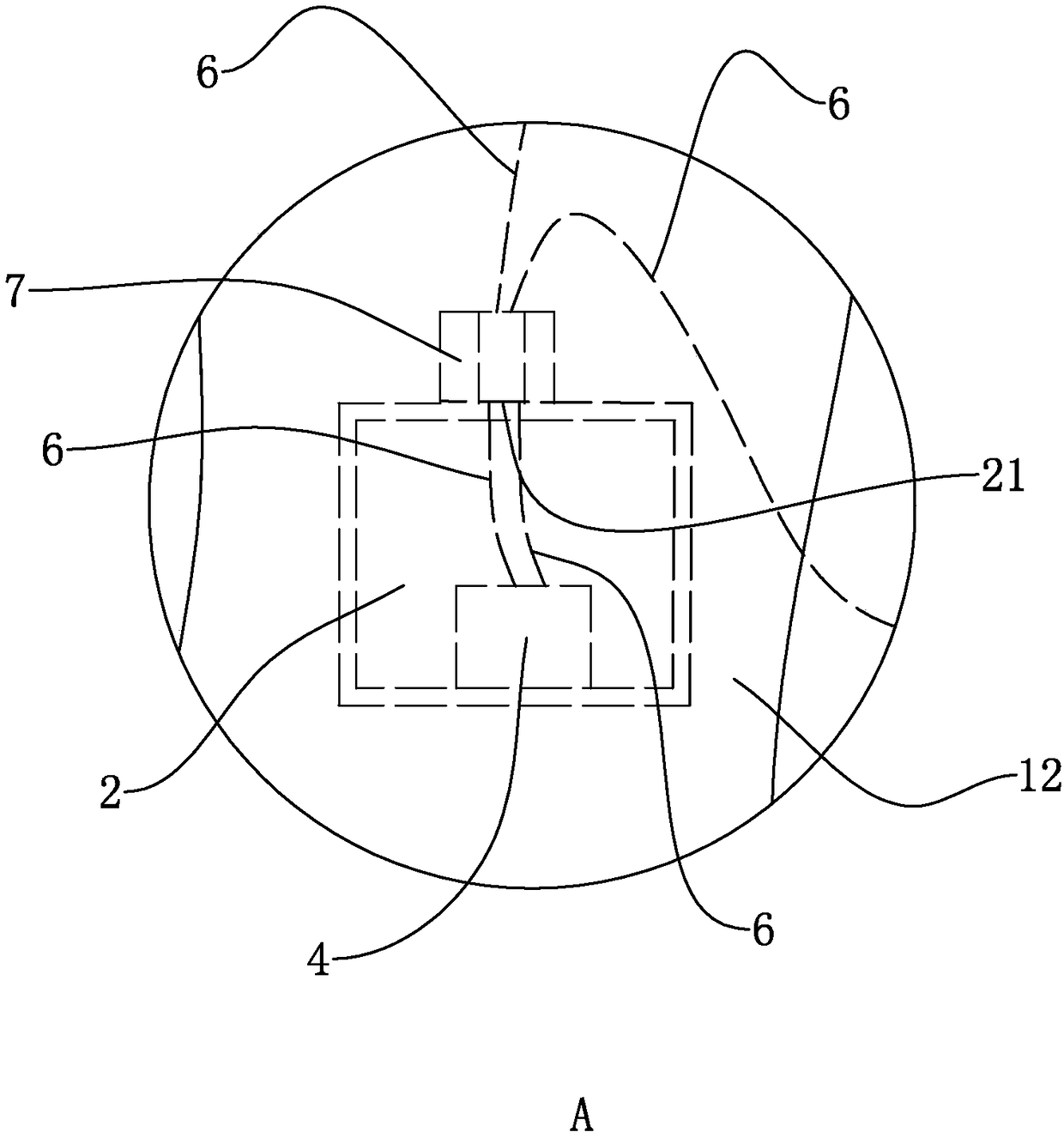

[0053] a heated garment such as figure 1 and figure 2 As shown, it includes a coat body 1, the coat body 1 is composed of an outer layer of fabric 11 and an inner lining 12, the outer surface of the outer layer of fabric 11 is provided with a pocket 2 at the waist position, and the heating clothes also include a pocket 2 located at the outer layer of fabric 11 and an inner lining 12. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com