Aerosol propellant grain ignition device and production method

An aerosol generation and generation agent technology, which is applied in fire rescue and other fields, can solve the problems of deflagration, explosion, structural stability and protection of powder columns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

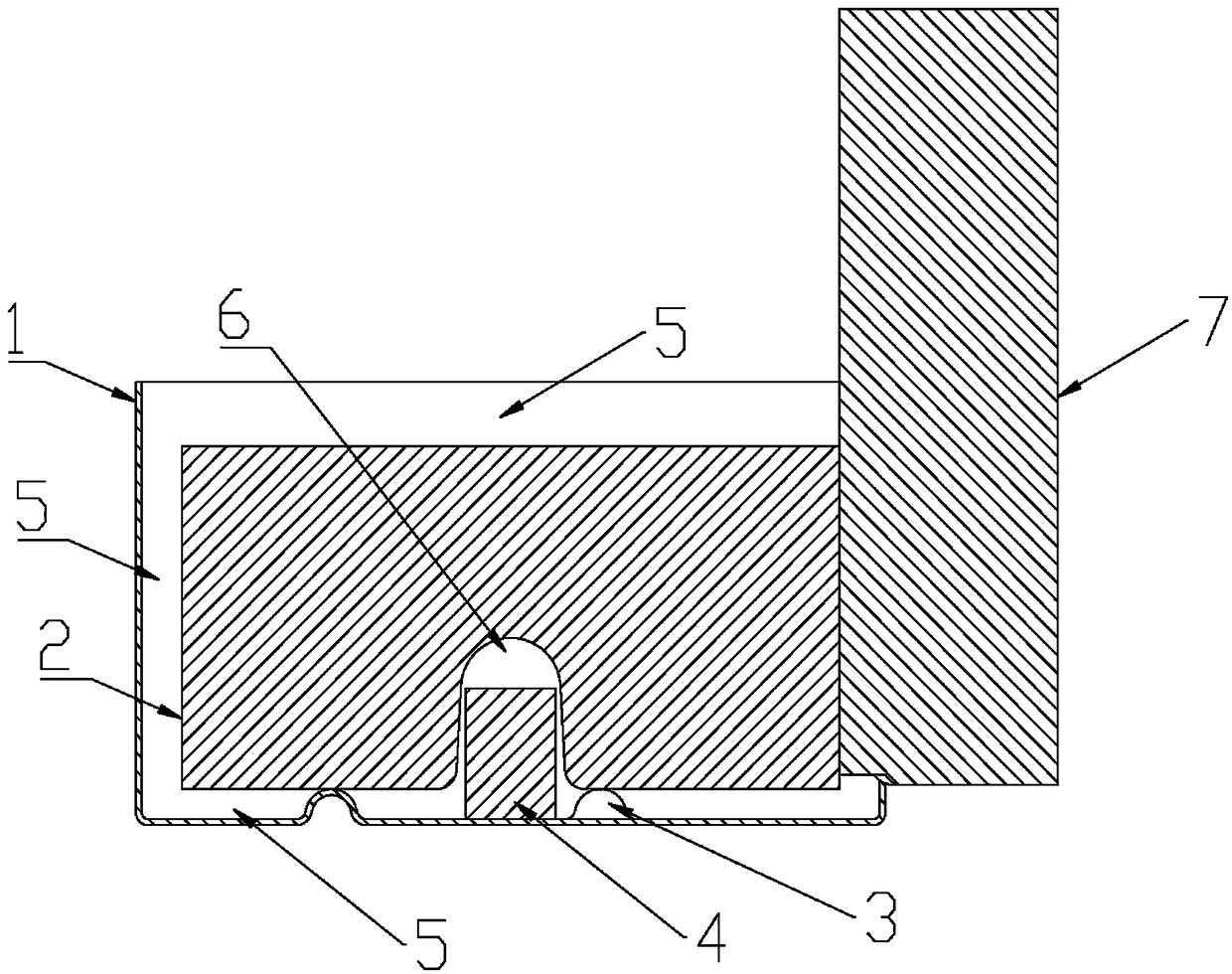

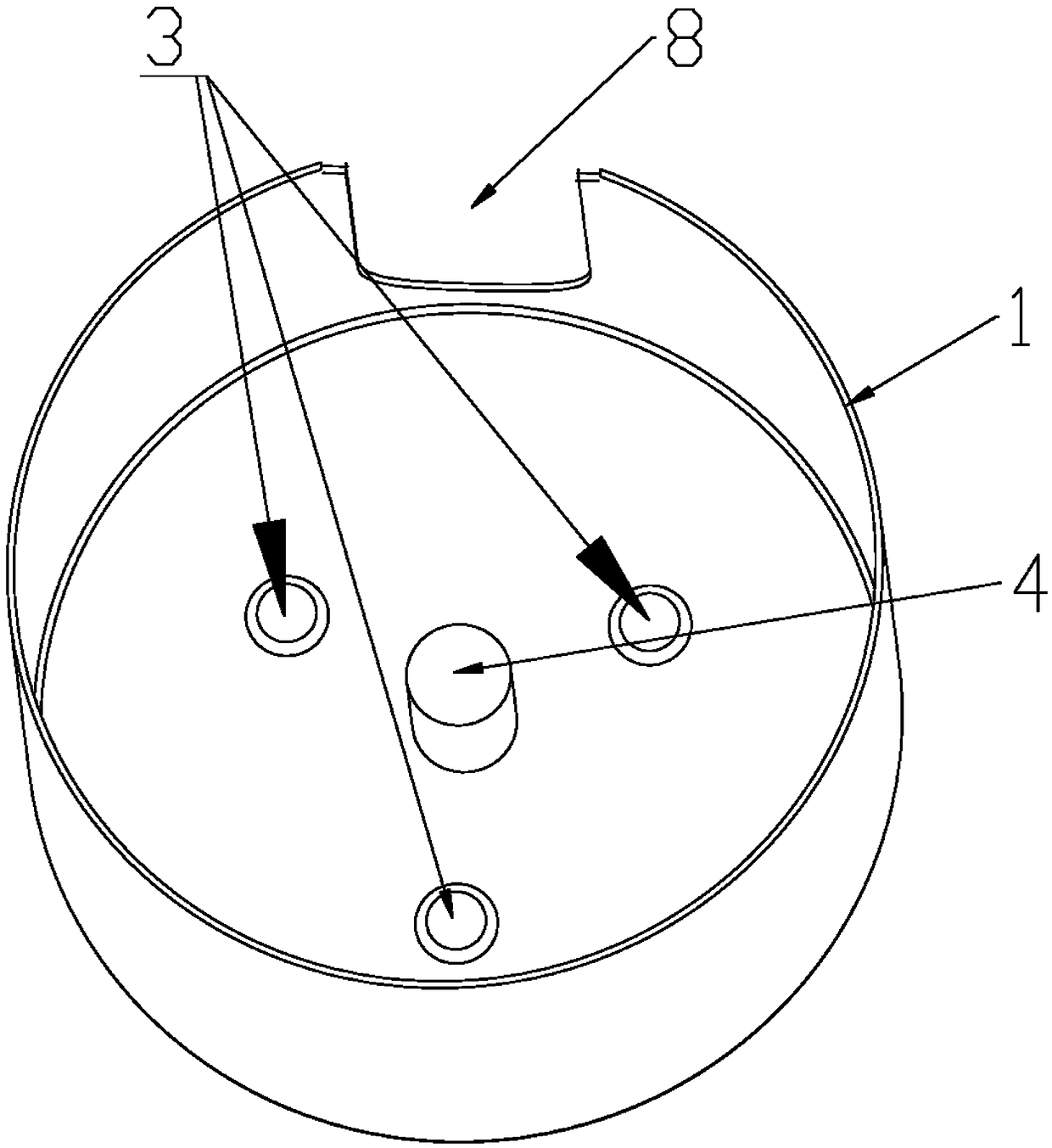

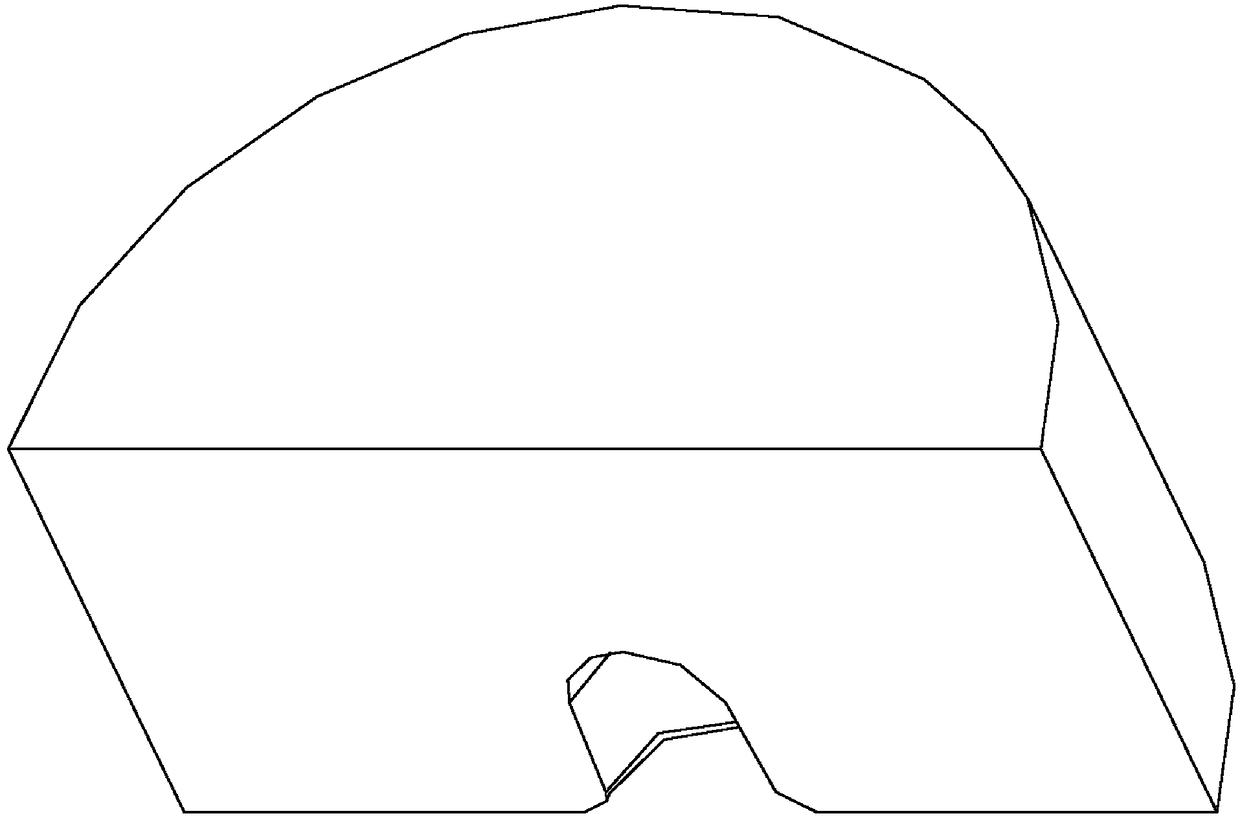

[0031] see Figure 1-4 , a kind of aerosol generating agent charge ignition device, it comprises generating agent cylinder 1, and described generating agent cylinder 1 is fixed and reaction container, and the side wall of described generating agent cylinder 1 is provided with opening 8; Said opening The dispensing jig 7 is positioned and installed on 8, and the bottom of the generator cartridge 1 is positioned and installed with a drug column 2 through the axial positioning structure 3 and the radial positioning structure 4.

[0032] Further, the gap between the generator cartridge 1 and the grain column 2 is filled with a silica gel isolation layer 5 and covers the entire grain column 2 .

[0033] Further, the dispensing jig 7 is in close contact with the side of the grain column 2 .

[0034] Further, the number of the dispensing jig 7 is at least one, and the number is determined according to the number of openings 8 on the side wall of the generator cartridge 1 .

[0035]...

Embodiment 2

[0041] The method for any aerosol generating agent grain ignition device, it comprises the following steps:

[0042] Step1: Put the formed aerosol generating agent grain 2 into the aerosol generating agent cartridge 1 with the axial positioning structure 3 and the radial positioning structure 4;

[0043] Step 2: Put the dispensing jig 7 into the opening 8 of the side wall of the aerosol generating agent cartridge 1 and ensure that the side of the dispensing jig 7 is in close contact with the side of the aerosol generating agent column 2;

[0044] Step 3: Inject a certain amount of liquid silica gel into the aerosol generating agent cylinder 1, and after the silica gel is allowed to stand and solidify, the relative positions of the powder column 2 and the generating agent cylinder 1 are fixed as a whole, and a stable silica gel isolation layer is formed between the two 5;

[0045] Step 4: Remove the glue dispensing jig 7 to expose the burning surface of the aerosol generating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com