A drawer type filter

A filter device and drawer-type technology, which is applied in the mechanical field, can solve the problems of blocking the filter hole of the filter element, and achieve the effects of preventing water leakage, ensuring airtightness, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

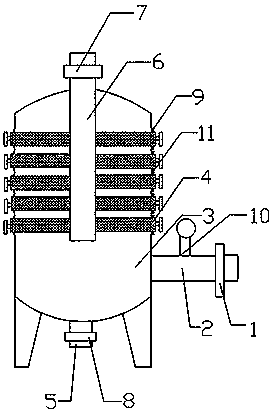

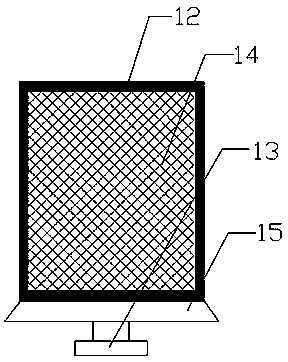

[0014] Figure 1-2 A specific embodiment of the present invention is shown: a drawer-type filter device, including a water inlet valve 1, a water inlet pipe 2, a filter tank body 3, a drawer-type filter screen 4, a sewage pipe 5, a central water outlet pipe 6, a water outlet valve 7, and a sewage discharge pipe. The valve 8 and the suction hole 9, the water inlet pipe 2 is set at the lower right corner of the filter tank body 3, the water inlet valve 1 is set on the water inlet pipe 2, the central outlet pipe 6 is set at the top of the filter tank body 3, and inserted into the tank body 3 , located at the center of the tank body 3, the water outlet valve 7 is arranged on the central outlet pipe 6, the suction holes 9 are equidistantly arranged on both sides of the filter tank body, and each side is provided with four suction holes 9, the draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com