Flexible bran removing device for rice grains

A technology of rice grains and rice, which is applied in the field of granular food polishing devices, can solve problems such as waste and loss of rice nutrients, and achieve the effects of reducing the rate of broken rice, preventing excessive polishing of brown rice, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

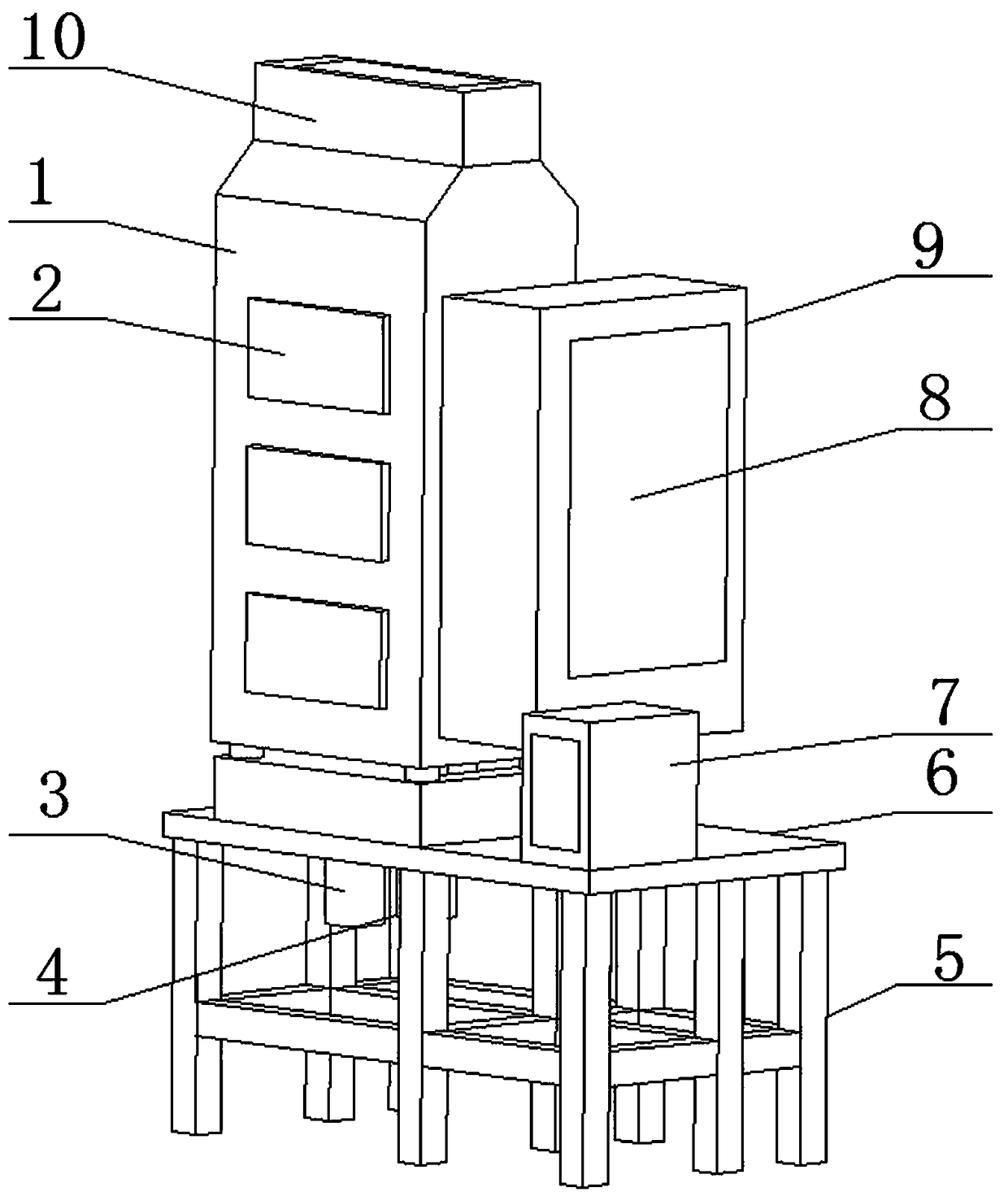

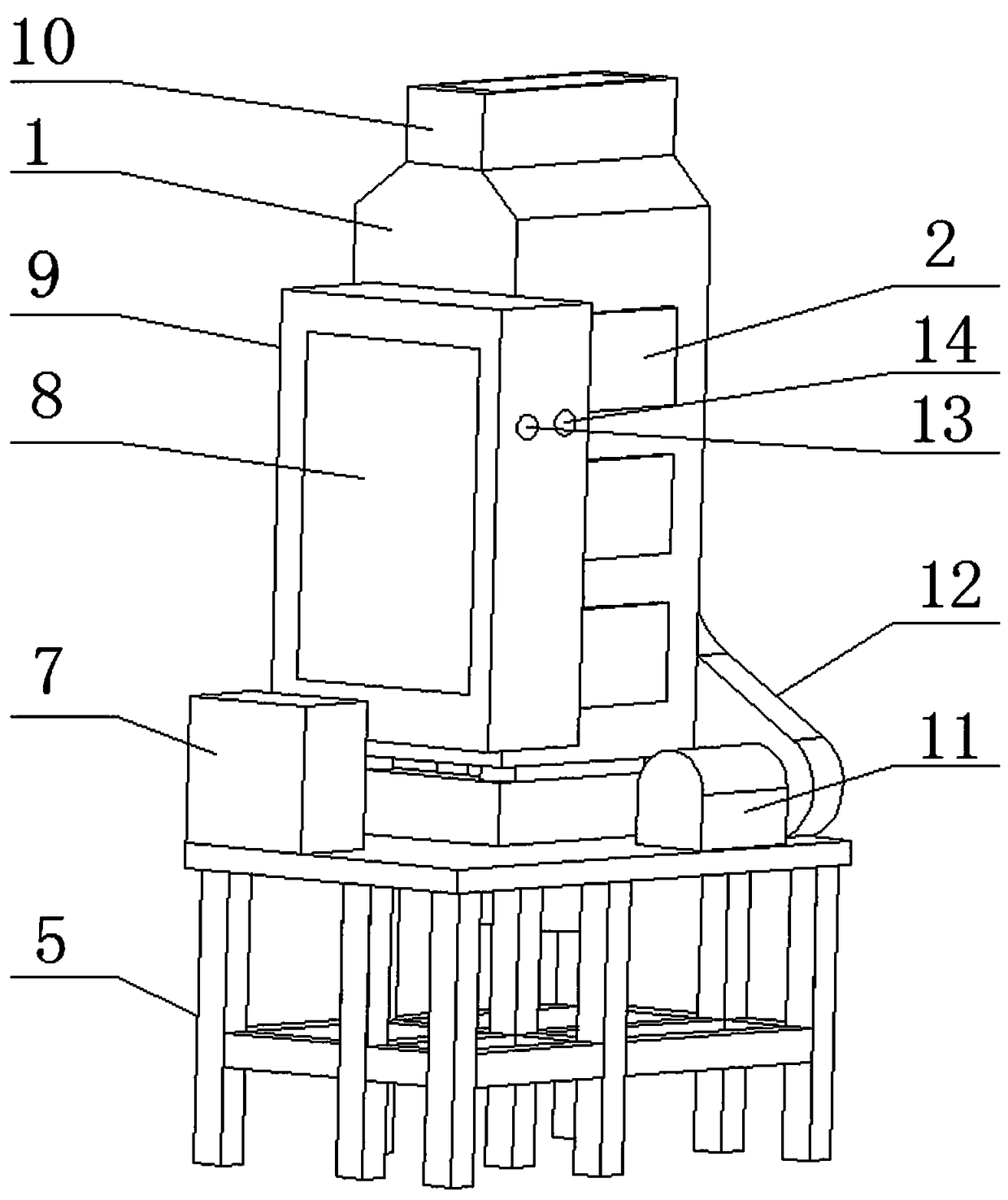

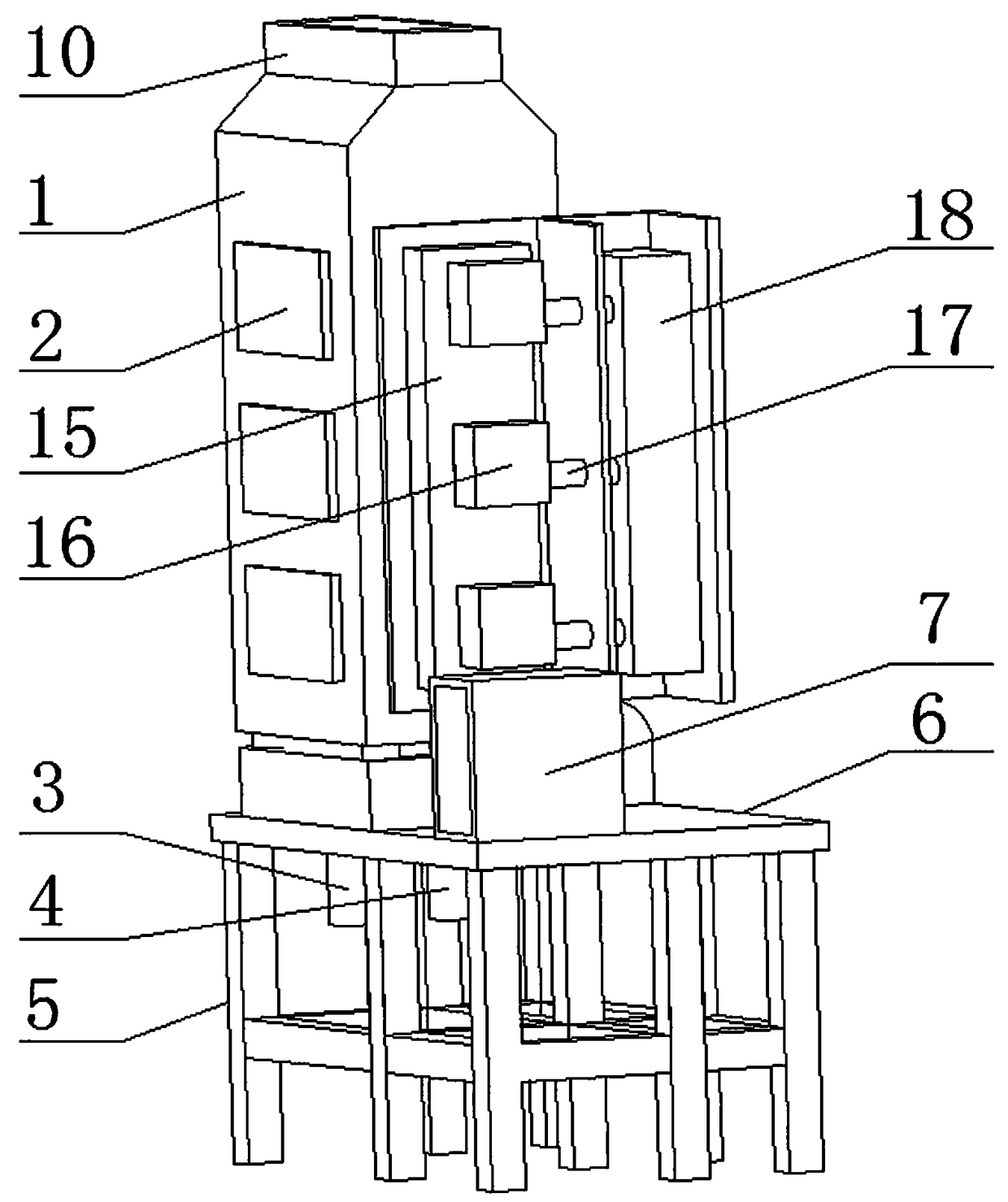

[0029] A flexible rice bran removal device, comprising a rice brushing mechanism and a bracket 5; characterized in that: the rice brushing mechanism is located above the bracket 5, the top surface of the bracket 5 is connected to a table 6, and the top surface of the table 6 is connected to brushing rice mechanism, one side of the rice brushing mechanism is provided with a pulley guard 12, and the other side is provided with a water vapor device; the rice brushing mechanism includes a rice brushing chamber housing 1, and the rice brushing chamber housing 1 The top is provided with a feed hopper 10, the bottom of the rice brushing chamber housing 1 is provided with a discharge hopper 3, and the discharge hopper 3 extends through the table top 6 to below the table top 6; the rice brushing chamber housing 1 is provided with a plurality of Bran brushing mechanism, the bran brushing mechanism is sequentially arranged inside the rice brushing room from top to bottom, and the chaff br...

Embodiment 2

[0039] The working principle of the present invention: in the present invention, the material enters into the chaff brushing mechanism through the feeding hopper 10 and the feeding channel 19, and the chaff brushing mechanism passes the cooperation between the rolling brush 20 and the sieve bucket 21, and the surface of the material is well cleaned. The bran powder is brushed off, and the bran powder is discharged through the waist hole 30 on the sieve bucket 21; The powder is all extracted; and the rice through the multi-layer bran brushing mechanism is discharged to the outside of the hopper 3 through the rice outlet channel 22.

[0040] In the present invention, the water and air device on the side of the rice brushing chamber housing 1 can well provide atomized water and air for the rice brushing mechanism, reduce the cost and electrical power, and improve the overall working efficiency of the equipment.

Embodiment 3

[0042] In the present invention, if Figure 5 As shown, the pulley of the motor drives the pulleys of other brushing mechanisms by connecting the pulleys of the bottom brushing mechanism. Adjust the speed of the roller brush 20 in each chaff brushing mechanism, so that the chaff brushing mechanism can adapt to the food of different particles and increase the diversity of its processed items.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com