A kind of diamond wire silicon chip cutting method

A technology of silicon wafer cutting and gold steel wire, applied in manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problems of uneven wire mesh tension, uneven thickness of silicon wafers, and high production costs, and achieve cutting Simple, good quality, raw material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

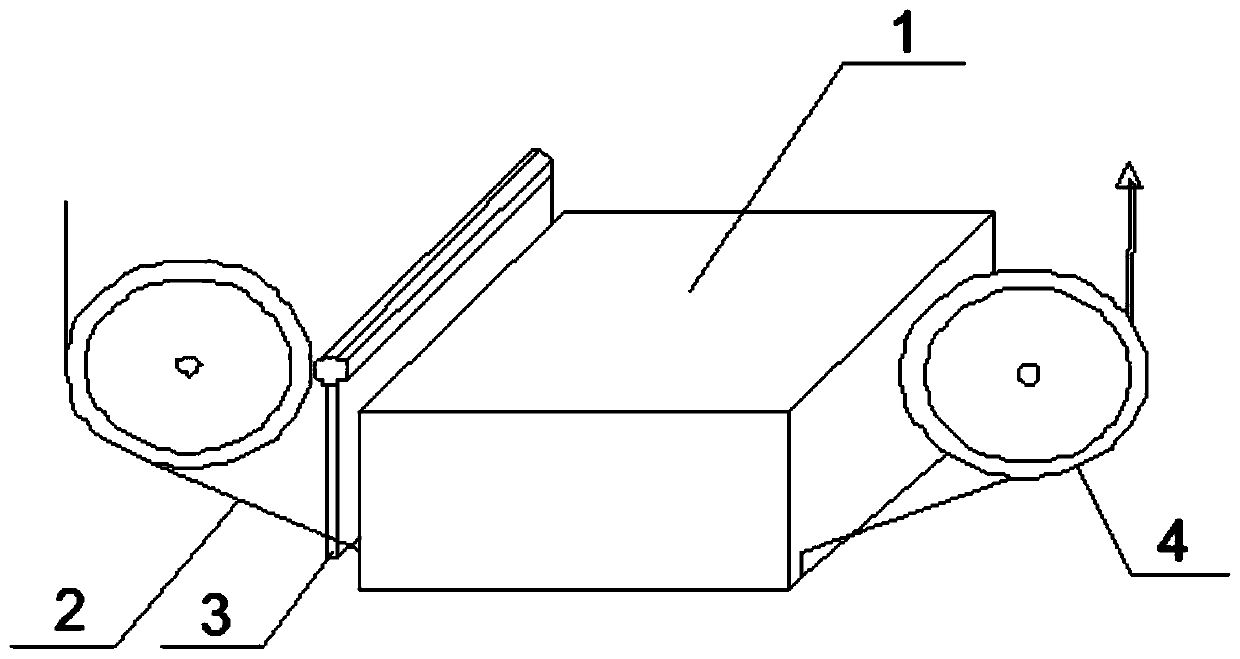

Image

Examples

Embodiment approach

[0040] Further, as a specific embodiment of a method for cutting silicon wafers with a diamond wire provided by the present invention, the specified tension value is 10-12N; the wire consumption for one cut is generally 3.5km, and after each cut is finished, If the tension of the wire mesh is loose, the cutting quality will be affected if it is directly cut into the next knife. Walk once to achieve the purpose of uniform tension. At this time, the gold steel wire 2 used for cutting the previous knife has all come out of the wire net and is retracted to the spool. Cutting silicon wafers under the condition of uniform tension can effectively improve the cutting ability and avoid producing thin and thick slices; among them, the specified tension value of 10-12N is based on the value set according to the current use of gold wire 2 with a diameter of 0.07mm.

[0041] Further, as a specific implementation of the method for cutting silicon wafers with a diamond wire provided by the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com