A high-strength composite cement aeolian mortar

A technology of compounding cement and aeolian sand, applied in the field of desert aeolian sand, can solve the problem of not completely solving the application problem of aeolian sand, and achieve the effects of reducing dry shrinkage of mortar, improving impermeability and saving resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

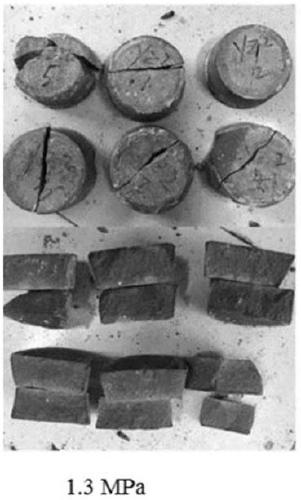

Image

Examples

Embodiment 1

[0026] A high-strength composite cement aeolian mortar, which consists of 100 parts by weight of aeolian sand, 33.3 parts of cement, 6.7 parts of fly ash, 16 parts of water, 4 parts of polycarboxylic acid water reducing agent, and 2 parts of melamine water reducing agent , 0.5 part of 400 viscosity cellulose ether, 0.5 part of K12.

Embodiment 2

[0028] A high-strength composite cement aeolian mortar, which is composed of: 100 parts of aeolian sand, 36.7 parts of cement, 18.3 parts of fly ash, 27.5 parts of water, 11.7 parts of polycarboxylic acid water reducing agent, and 2.3 parts of melamine water reducing agent , 400 viscosity cellulose ether 2 parts, K126 parts.

Embodiment 3

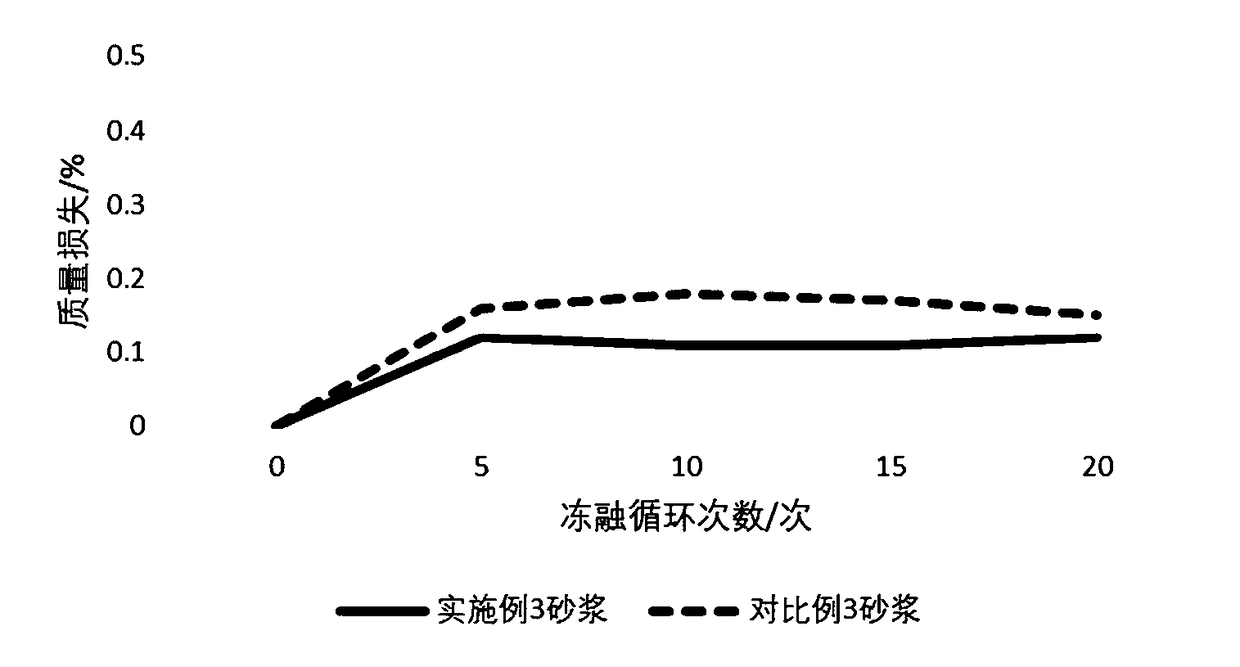

[0030] A high-strength composite cement aeolian mortar, with a gel-sand ratio (weight ratio of cementitious material to aeolian sand) of 0.5, a water-binder ratio (weight ratio of water to cementitious material) of 0.4, and its weight parts composition: wind 100 parts of sand, 36 parts of cement, 14 parts of fly ash, 20 parts of water, 8 parts of polycarboxylic acid water reducer, 2 parts of melamine water reducer, 1 part of 400 viscosity cellulose ether, 5 parts of K12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical insulator | aaaaa | aaaaa |

| electrical insulator | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com