Full flexible passive pressure sensor based on microdroplet, and manufacturing method thereof, and detection method thereof

The technology of a pressure sensor and a manufacturing method is applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic elements, instruments, etc., which can solve the problem of limited space for sensitivity improvement, and achieve the effect of improving measurement accuracy and strong resistance to parasitic capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

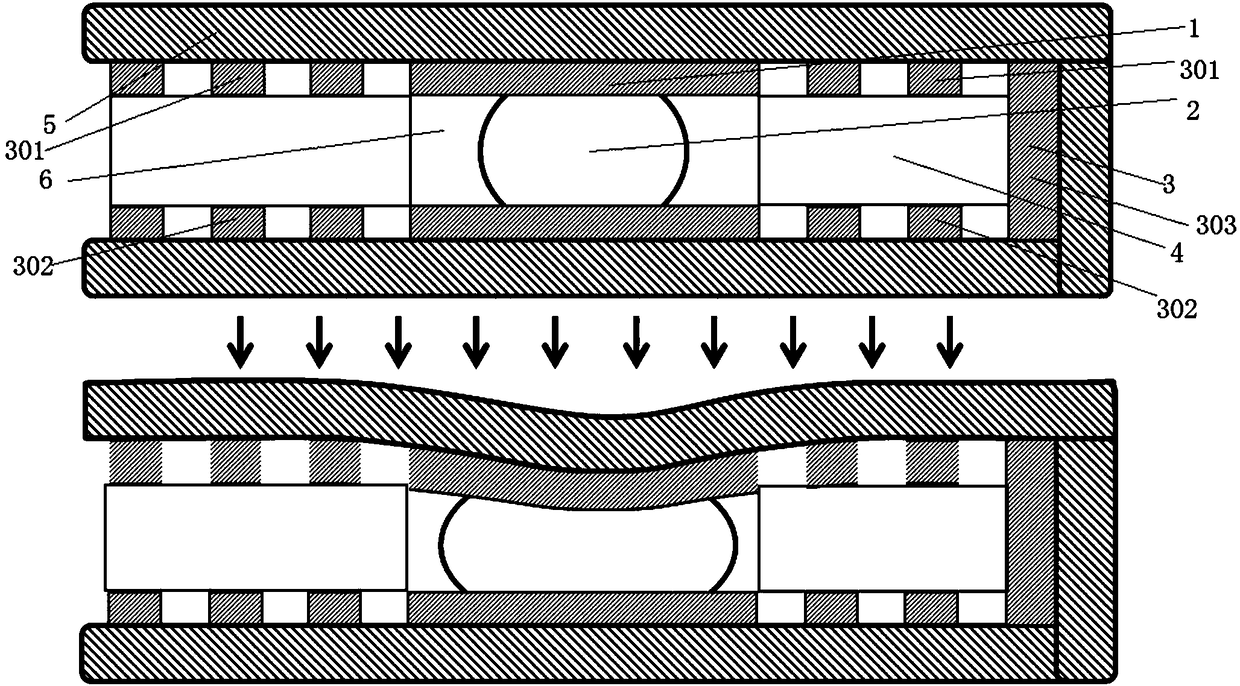

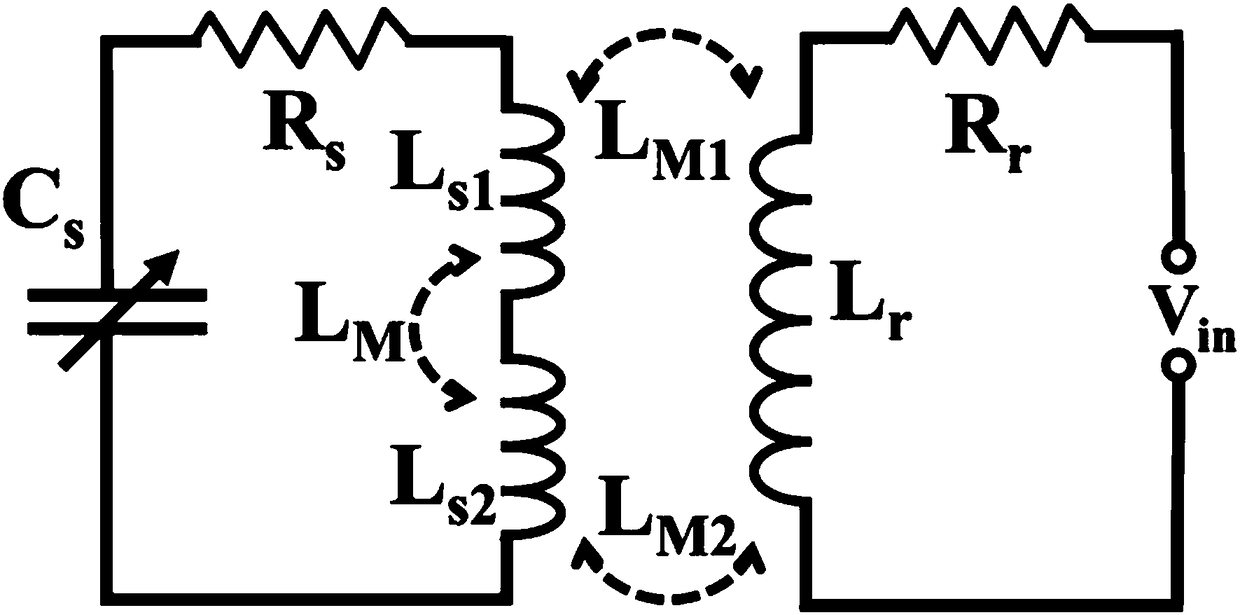

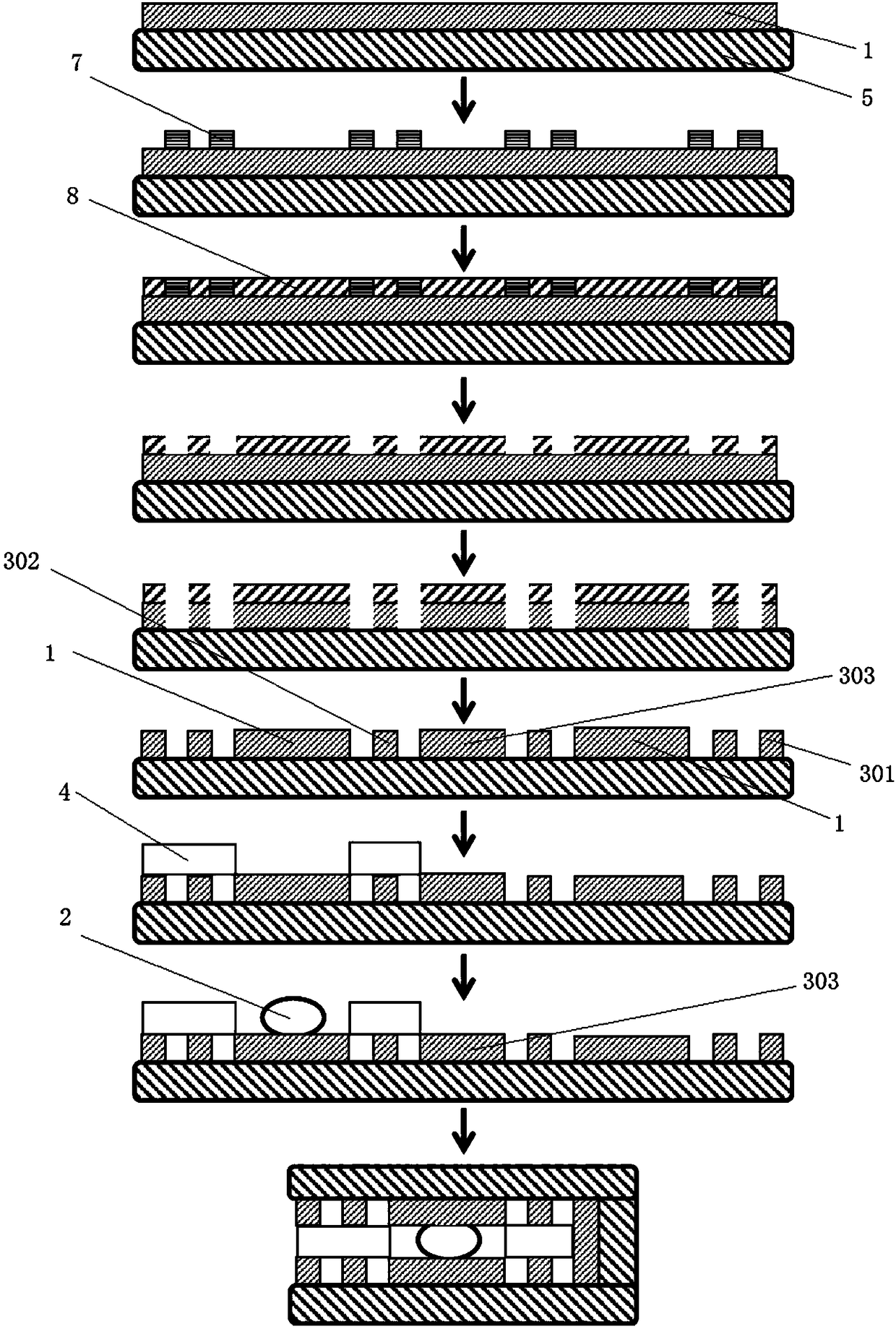

[0049]A fully flexible passive pressure sensor based on micro-droplets, including: a two-layer conductive electrode 1 forming a sensing chamber, a sensing droplet 2 dropped in the sensing chamber, and sensor coils 3 arranged on both sides of the sensing chamber. The spacer layer 4 in the sensor coil 3 , the flexible cover film 5 covering the conductive electrode 1 and the sensor coil 3 , and a space 6 for the sensing droplet 2 to expand is provided in the sensing chamber. The sensor coil 3 comprises: an upper half coil 301, a lower half coil 302, a folded portion 303 between the upper half coil 301 and the lower half coil 302; the duty coil and the off duty coil are made of a polyimide film (Cu- PI film) after making a copper pattern and then folding it. As a preference, the two conductive electrodes 1 are two solid concentric circles. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com