Tensioning anchoring testing device and method for pre-stress carbon fiber plate reinforced steel beam

A carbon fiber board and experimental device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of reducing the bearing capacity of steel beams, destroying the integrity of steel beams, etc., so as to improve the ability to transfer loads and reduce experiments. The effect of high cost and experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

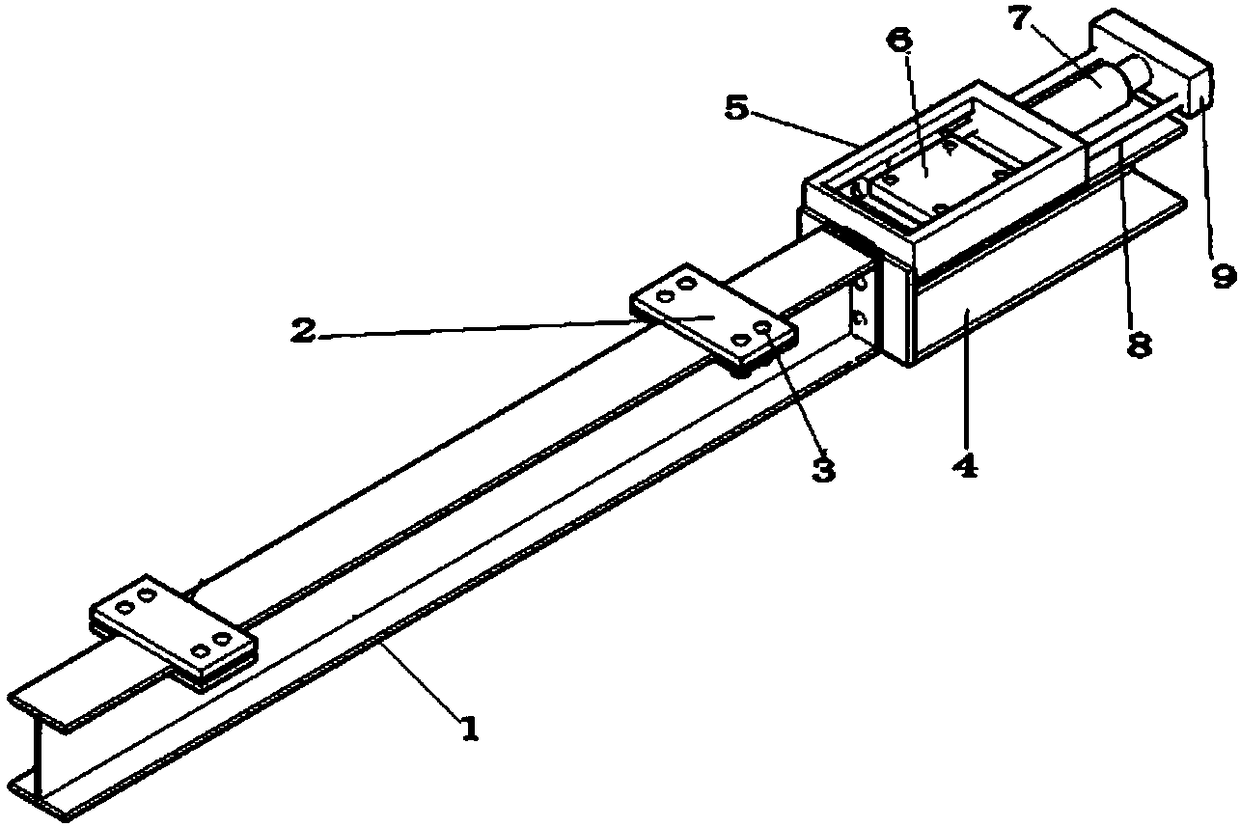

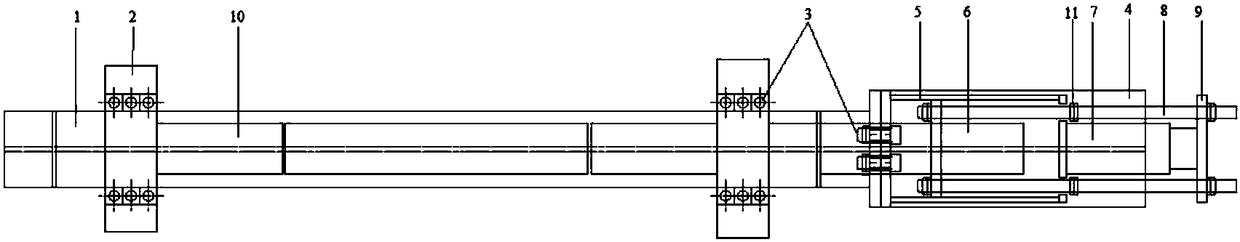

[0037] refer to Figure 1 to Figure 6 , the present invention is a prestressed carbon fiber plate reinforced steel beam tension anchor experiment device, including: anchor fixture 2 and a tension device.

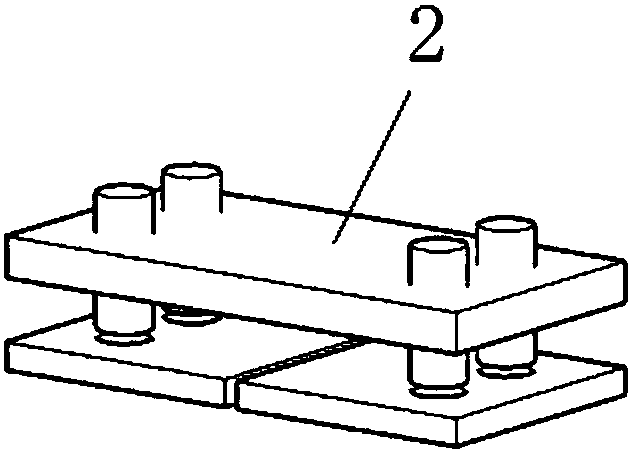

[0038] refer to Figure 1 to Figure 3 , the number of anchoring fixtures 2 is at least two, the anchoring fixture 2 includes an upper splint and a lower splint, the upper splint and the lower splint are respectively provided with connecting holes, and connecting bolts 3 are installed in the connecting holes, and the upper splint and the lower splint are connected by bolts 3 The CFRP plate 10 can be fixed on the steel beam 1 to be reinforced. The lower surface of the upper splint is provided with friction grooves, the friction grooves are wavy stripes, and the lower splint is welded in parallel on the flanges on both sides of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com