Semi-supervised hybrid model-based polypropylene melting index prediction method

A melt index and hybrid model technology, which is applied in chemical property prediction, electrical digital data processing, special data processing applications, etc., can solve the problem that the global model is difficult to provide satisfactory prediction accuracy, and does not have enough, to achieve abnormal sample classification guarantee, model Reliable, time- and energy-saving results for training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The method for predicting the melt index of polypropylene based on the semi-supervised mixing model of the present invention will be further described in conjunction with specific examples below. It should be pointed out that the described embodiments are only intended to enhance the understanding of the present invention, and do not limit the present invention in any way.

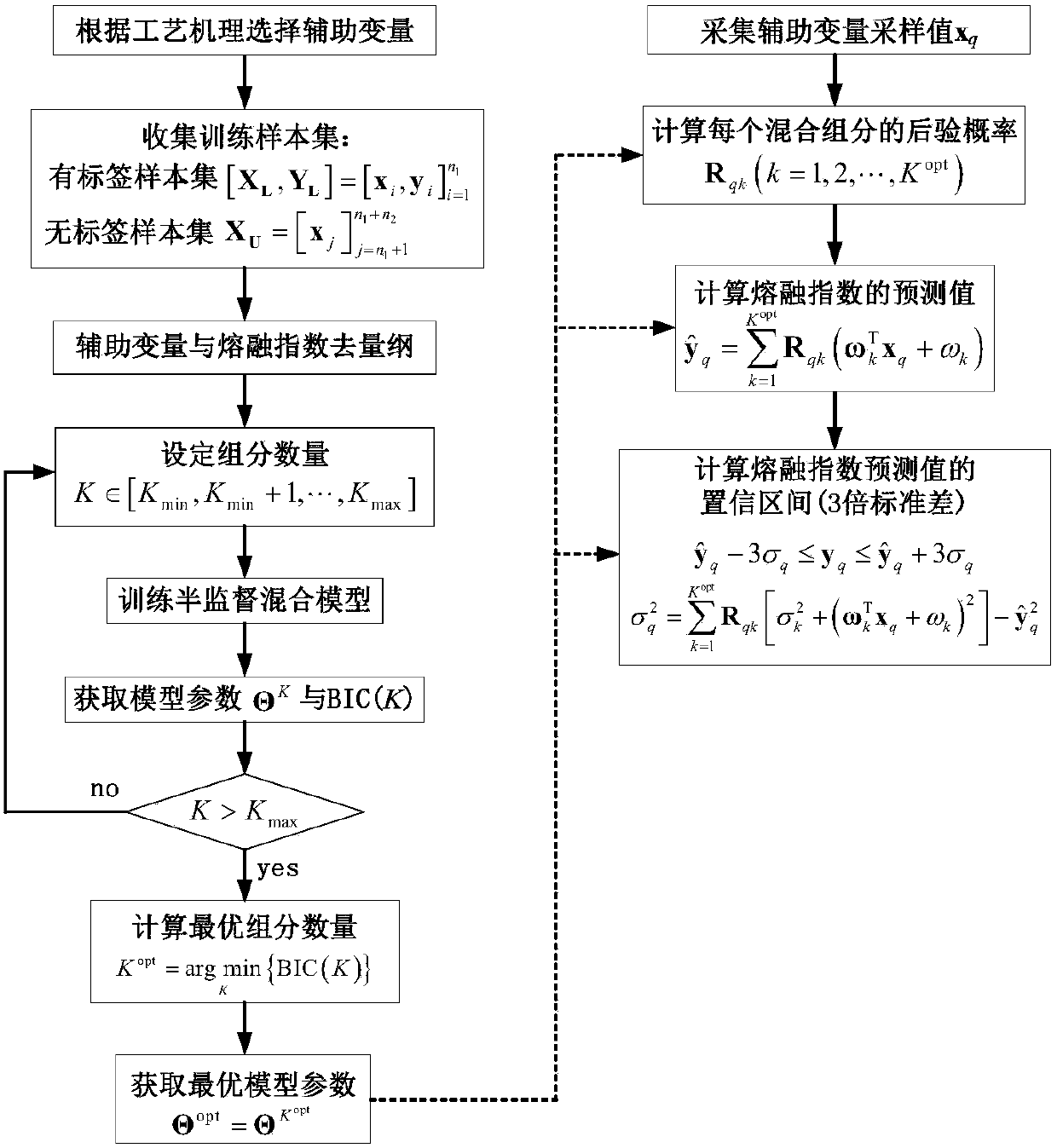

[0047] A method for predicting the melt index of polypropylene based on a semi-supervised mixture model, such as figure 1 As shown, it specifically includes the following steps:

[0048] (1) Select the auxiliary variable x∈R associated with the polypropylene melt index y m , where m represents the number of auxiliary variables;

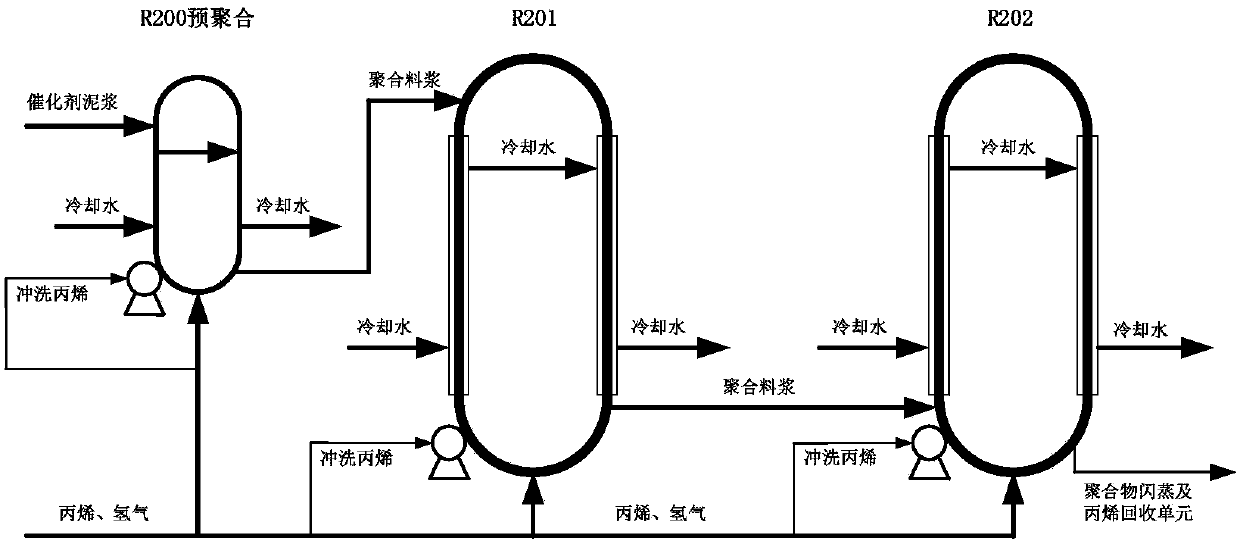

[0049] This embodiment is based on a certain petrochemical company Spheripol-II liquid phase bulk method polypropylene production process (such as figure 2 Shown) mechanism analysis, select the 8 variables that have the greatest impact on the melt index as auxiliary vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com