Mount structure

A technology of structure and crystal structure, which is applied in the manufacture of electrical solid devices, semiconductor devices, semiconductor/solid devices, etc., can solve the problems of large thermal stress, cracks, large joint area, etc., and suppress the occurrence and development of cracks , the effect of large thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

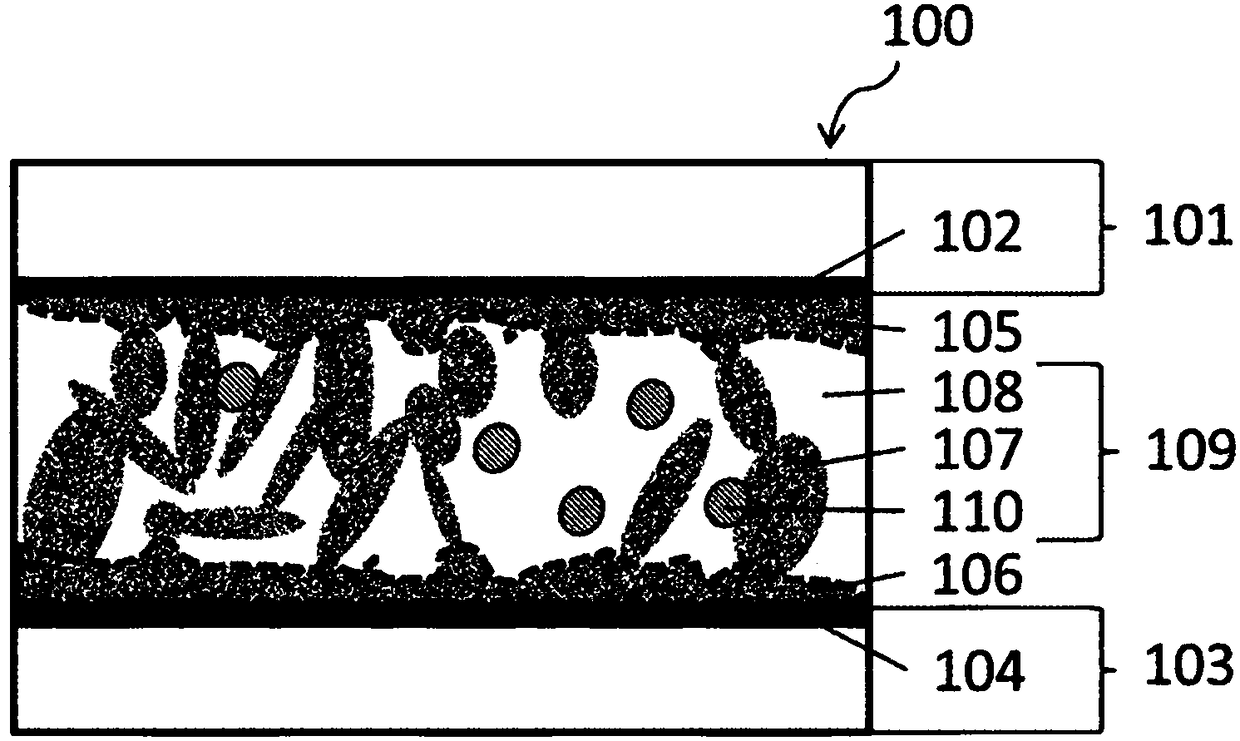

[0054] In order to confirm the effect of the present invention, regarding the above-mentioned embodiment, a 10mm 2 、15mm 2 The large-area bonded installation structure is verified. Here, as the first member 101, a 15mm steel plate with Ni plating on the back as the first material to be joined 102 is used. 2 Si chips. In addition, as the second member 103 , a Cu plate having Ni plating as the second material to be joined 104 on the back was used. The installation structure is manufactured according to the following steps.

[0055] First, flux is applied to a Cu plate as the second member 103, and a foil of a solder material forming the bonding material layer 109 is supplied thereon. In addition, flux is applied to the foil of the solder material, and the Si chip as the first member 101 is mounted thereon. It is heated to 280°C to melt the solder material. In the melted state, pressing is performed by applying a downward force from above the Si chip, and the layer thicknes...

Embodiment 3

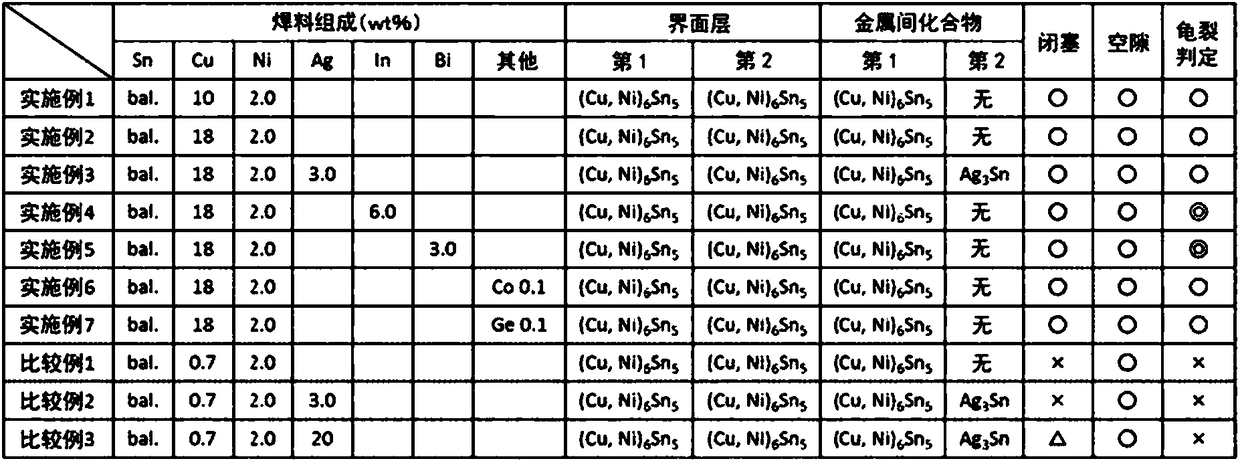

[0062] The Ag contained in the solder materials of Example 3 and Comparative Example 2 was equal to the Ag content of the second intermetallic compound 110. 3 Sn exists in the form of Sn and is dispersed in the bonding material layer 109 .

[0063] On the other hand, in Comparative Examples 1 and 2, the content of Cu was small, so the (Cu, Ni) of the first intermetallic compound 107 6 sn 5 Less, unable to confirm occlusion. In addition, in Comparative Example 3, the content of Ag is large, so Ag 3 A large amount of Sn exists in the form of the second intermetallic compound 110 to form a closed structure.

[0064] In addition, elements other than Cu and Ni contained in the welding materials of Examples 4 to 7 do not exist in the form of the first intermetallic compound 107, and In and Bi are solid-dissolved in the stress relaxation material 108, and Co and Ge are trace amounts. Although not observed, it is considered to be contained in any one of the first interface layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com