Magnetic resonance hospital bed horizontal motion driving structure

A magnetic resonance bed, horizontal motion technology, applied in medical science, sensors, diagnostic recording/measurement, etc., can solve problems such as electromagnetic interference, affecting imaging quality, and large power, eliminating electromagnetic interference, simplifying shielding structure, reducing The effect of push and pull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

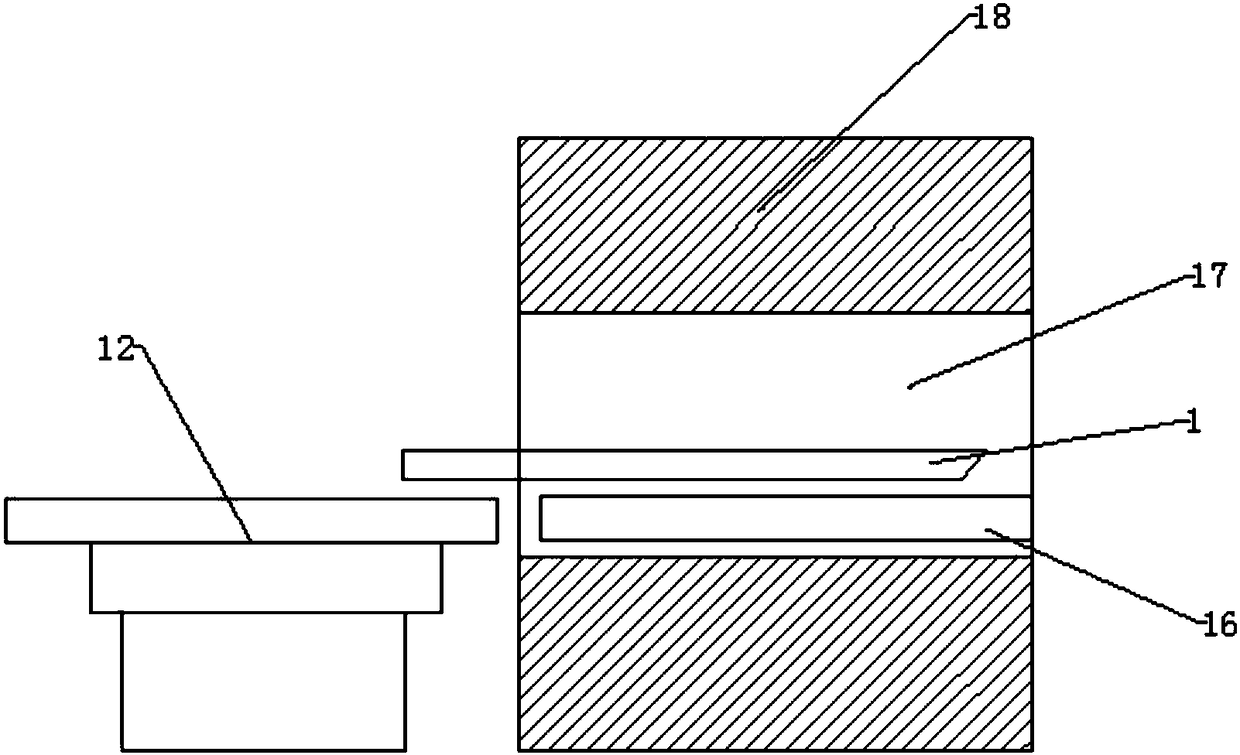

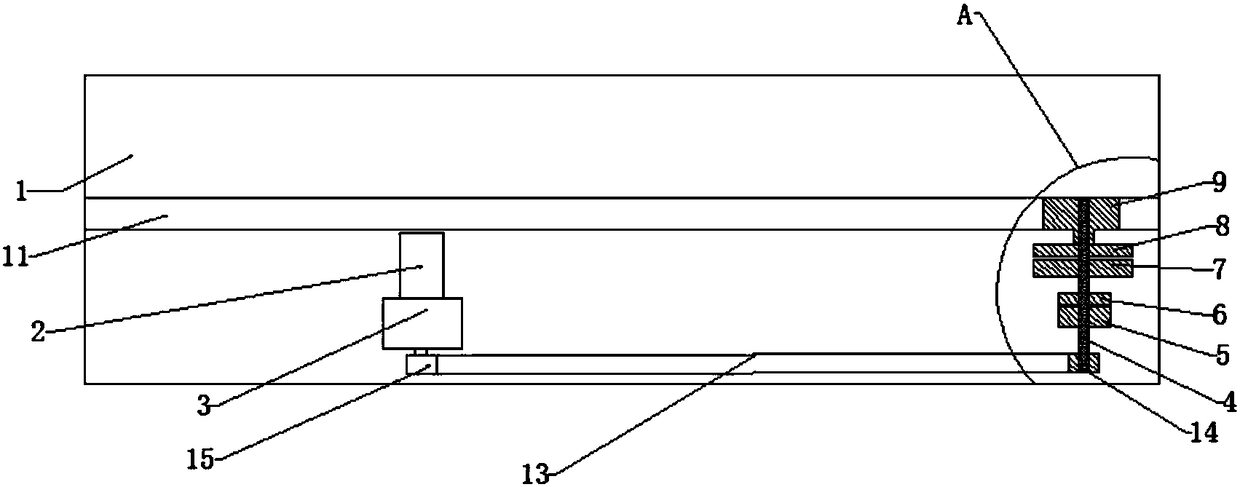

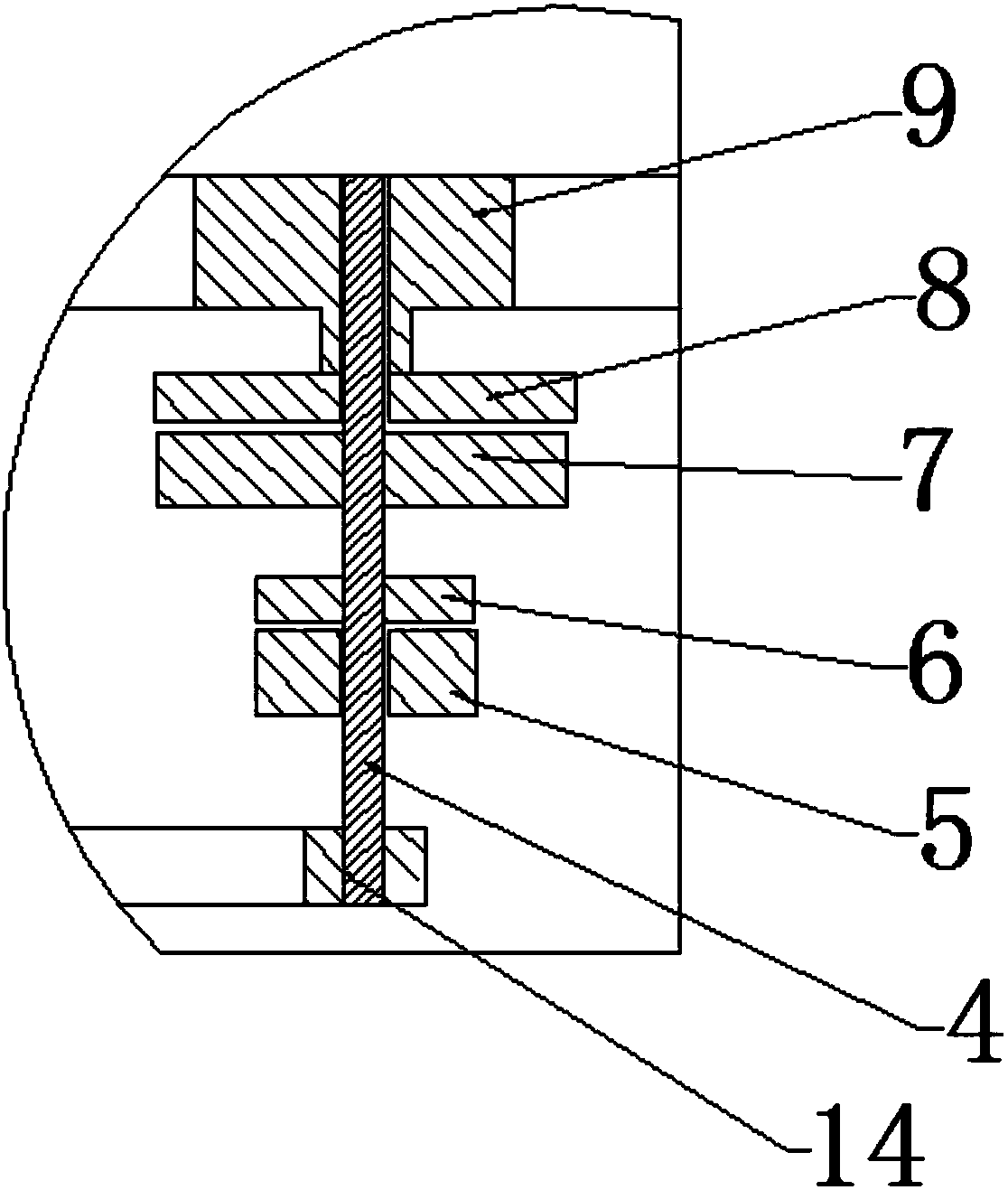

[0022] like figure 2 , 3 , 4, the magnetic resonance hospital bed horizontal motion drive structure disclosed by the present invention includes a bed board 1, a motor 2, a reducer 3, a transmission mechanism, a through shaft 4, a brake component A5, a brake component B6, a clutch component A7, and a clutch component B8 , driving gear 9 and driven gear 10, rack 11 is installed at the bottom of described bed board 1;

[0023] The motor 2 is installed on the main body 12 of the hospital bed, and the motor 2 is a servo motor. The reducer 3 is directly connected in series with the output shaft of the motor 2, the output shaft of the reducer 3 is equipped with an active synchronous wheel 15, and the active synchronous wheel 15 transmits power to the driven synchronou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com