Glass fiber enhanced PC (Polycarbonate) and preparation method thereof

A glass fiber and glass fiber technology, which is used in the field of glass fiber reinforced PC and its preparation, can solve the problems of reduced medium uniformity and light transmittance, no heat resistance and modulus, and can not add too many additives, etc. Good light transmittance, high elasticity, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

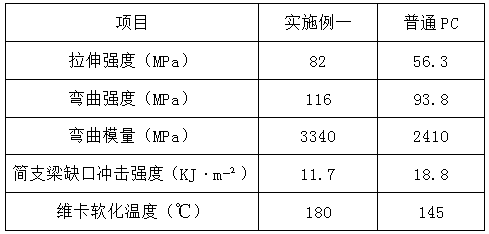

Examples

Embodiment 1

[0023] A glass fiber reinforced PC, comprising: 78% of PC substrate, 11% of glass fiber, 6% of graphite fiber, 0.7% of high modulus additive, 1.2% of light diffusing agent, 0.2% of antioxidant, by weight percentage, The rest are compatibilizers.

[0024] Specifically, the high modulus additive is produced by pyrolyzing random copolymerized pp plastic particles.

[0025] A preparation method of glass fiber reinforced PC, comprising the following steps:

[0026] 1) Add random copolymerized pp plastic particles into a high-temperature and high-pressure reactor, and feed N 2 After emptying, heat up and crack;

[0027] 2) After the cracking is completed, the high modulus additive is prepared by degassing and cooling down;

[0028] 3) Add glass fiber, antioxidant and compatibilizer into the reaction kettle at the same time, and carry out three-stage mixing and stirring at the speed of 2000-2500r / min to obtain No. 1 material; the mixing temperature of the first stage is 122°C, th...

Embodiment 2

[0037] A kind of glass fiber reinforced PC and preparation method thereof as described in embodiment 1, can also adopt following process:

[0038] In terms of weight percentage, the raw material formula is: 83% of PC substrate, 9% of glass fiber, 3% of graphite fiber, 0.6% of high modulus additive, 1.7% of light diffusing agent, 0.3% of antioxidant, and the rest are additives. Toner.

[0039] The cracking temperature is 580° C., and the cracking time is 1.2 h.

[0040] In step 3), the mixing temperature of the first section is 117°C, and the mixing time is 5 minutes; the mixing temperature of the second section is 134°C, and the mixing time is 3 minutes; the mixing temperature of the third section is 113°C, and the mixing time is for 20min.

[0041] In step 4), the stirring time is 10-15 minutes, and then the temperature is raised to 47° C., and then stirred for 8 minutes.

[0042] In step 6), the extrusion temperatures are 180°C, 253°C, 260°C, 267°C, and 269°C in sequence....

Embodiment 3

[0044] A kind of glass fiber reinforced PC and preparation method thereof as described in embodiment 1, can also adopt following process:

[0045] In terms of weight percentage, the raw material formula is: 85% of PC substrate, 3% of glass fiber, 8% of graphite fiber, 0.5% of high modulus additive, 2% of light diffusing agent, 0.1% of antioxidant, and the rest are additives. Toner.

[0046] The cracking temperature is 540° C., and the cracking time is 2 hours.

[0047] In step 3), the mixing temperature of the first section is 130°C and the mixing time is 5 minutes; the mixing temperature of the second section is 120°C and the mixing time is 3 minutes; the mixing temperature of the third section is 120°C and the mixing time is for 20min.

[0048] In step 4), the stirring time is 10 min, and then the temperature is raised to 60° C., and then stirred for 5 min.

[0049] In step 6), the extrusion temperatures are 182°C, 212°C, 273°C, 261°C, and 278°C in sequence.

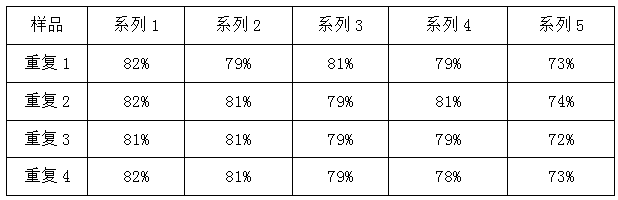

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com