Nuclear reactor pressure regulator safety valve water seal test system and method

A kind of technology of pressure stabilizer safety valve and nuclear reactor, which is applied in the testing of machine/structural parts, instruments, testing of mechanical parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

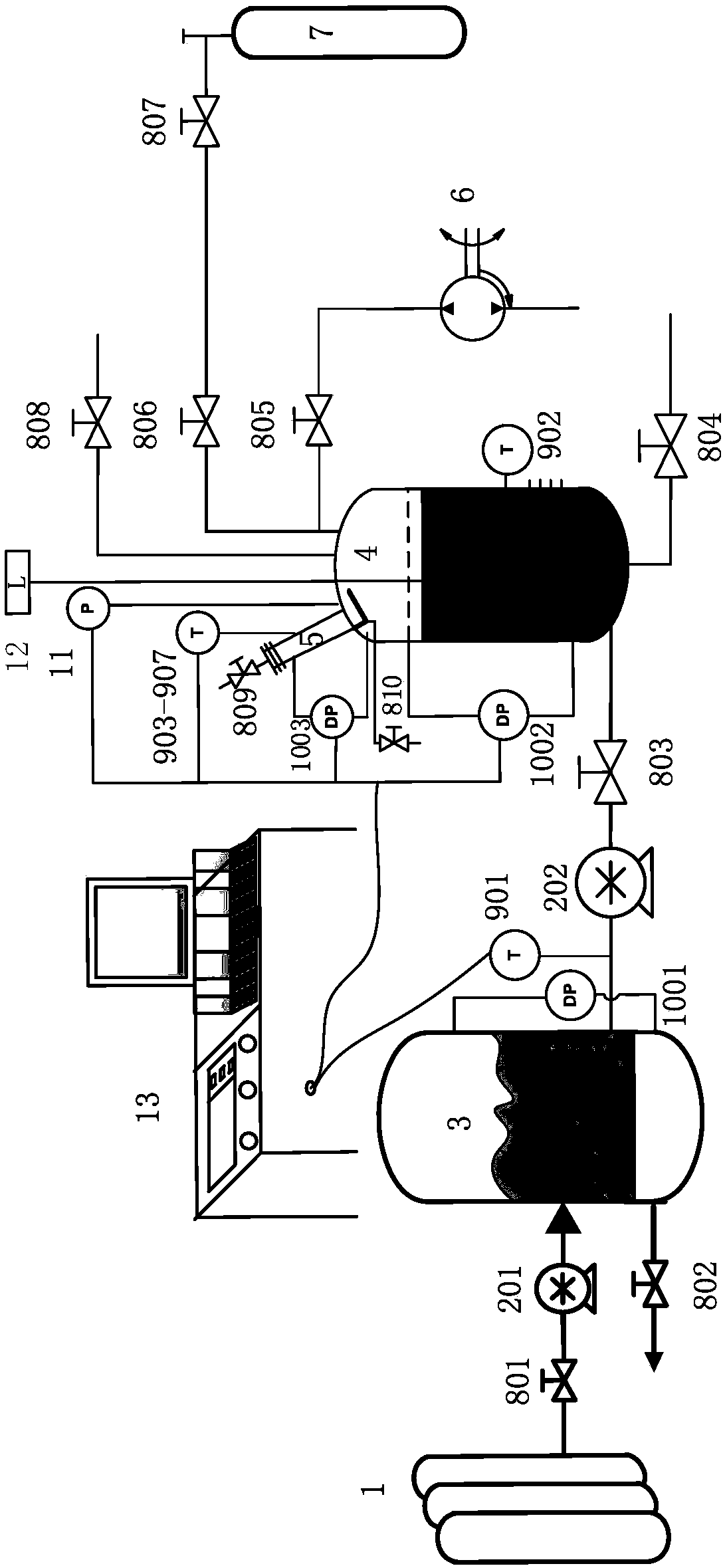

[0034] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0035] Such as figure 1 As shown, a nuclear reactor pressurizer safety valve water seal test system includes a deionized water production system 1, a first supplementary water pump 201 connected to the first flow control valve 801 of the deionized water production system, and the first supplementary water pump 201 is additionally One end is connected to the heating water tank 3, and the lower end of the heating water tank 3 is connected to the first drain valve 802. At the same time, the heating water tank 3 has multiple sets of heating rods built in, and the power of each heating rod is 60kW; A differential pressure transmitter 1001; the first temperature sensor 901 is installed at the outlet of the heating water tank 3; in the circuit, it serves to provide deionized water lower than the saturation temperature for the test circuit, and at the same time ensures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com