Transmission electron microscope in-situ sample holder head and sample holder comprising holder head

An electron microscope and sample rod technology, applied in the field of sample rods, can solve the problems of heating the sample rod, such as high heat generation, high experimental cost, and difficult sample preparation, and achieve the effects of reducing thermal drift, reducing operation difficulty, and reducing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

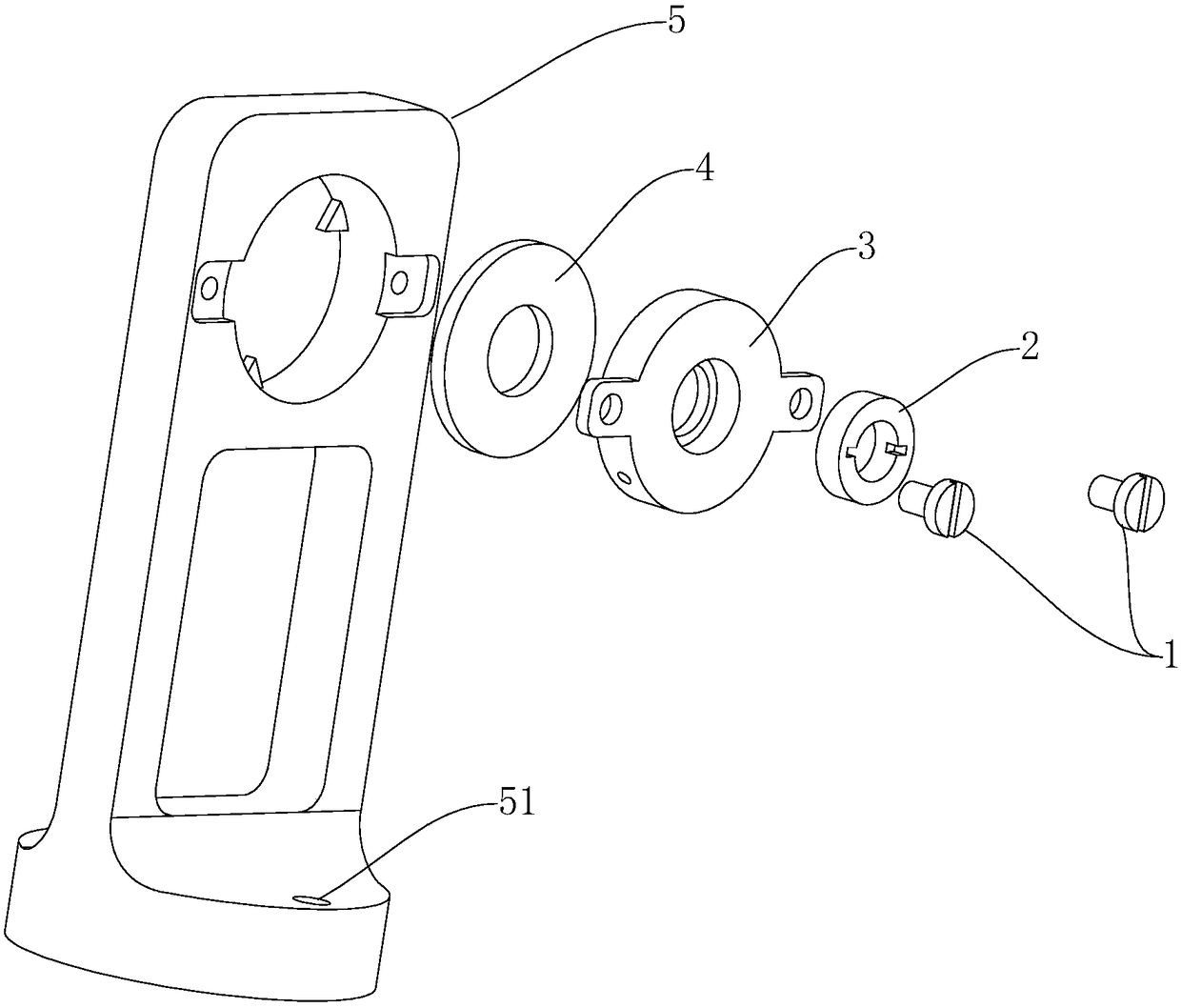

[0037] The invention provides a transmission electron microscope in-situ ceramic heating sample rod head, such as figure 1 As shown, including the sample rod head body 5, the front end of the sample rod head body 5 is provided with a through hole, and the through hole is provided with a ceramic heating ring 4, a sample holder 3, a sample pressing piece 2, a ceramic heating ring 4, The sample holder 3 and the sample pressing tablet 2 are stacked in sequence and the axis coincides with the axis of the through hole. The sample rod head is provided with a transmission hole through the ceramic heating ring 4, the sample holder 3 and the sample pressing tablet 2 on the coincident axis so that the electron beam can pass through. In this way, the sample pressing piece 2 is placed in the step hole where the sample is placed in the center of the sample h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com