LED packaging technology and LED packaging system

A technology of LED packaging and packaging technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems that affect product reliability, reduce packaging brightness, and generate bubbles, so as to ensure quality and pass efficiency, improve LED service life, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

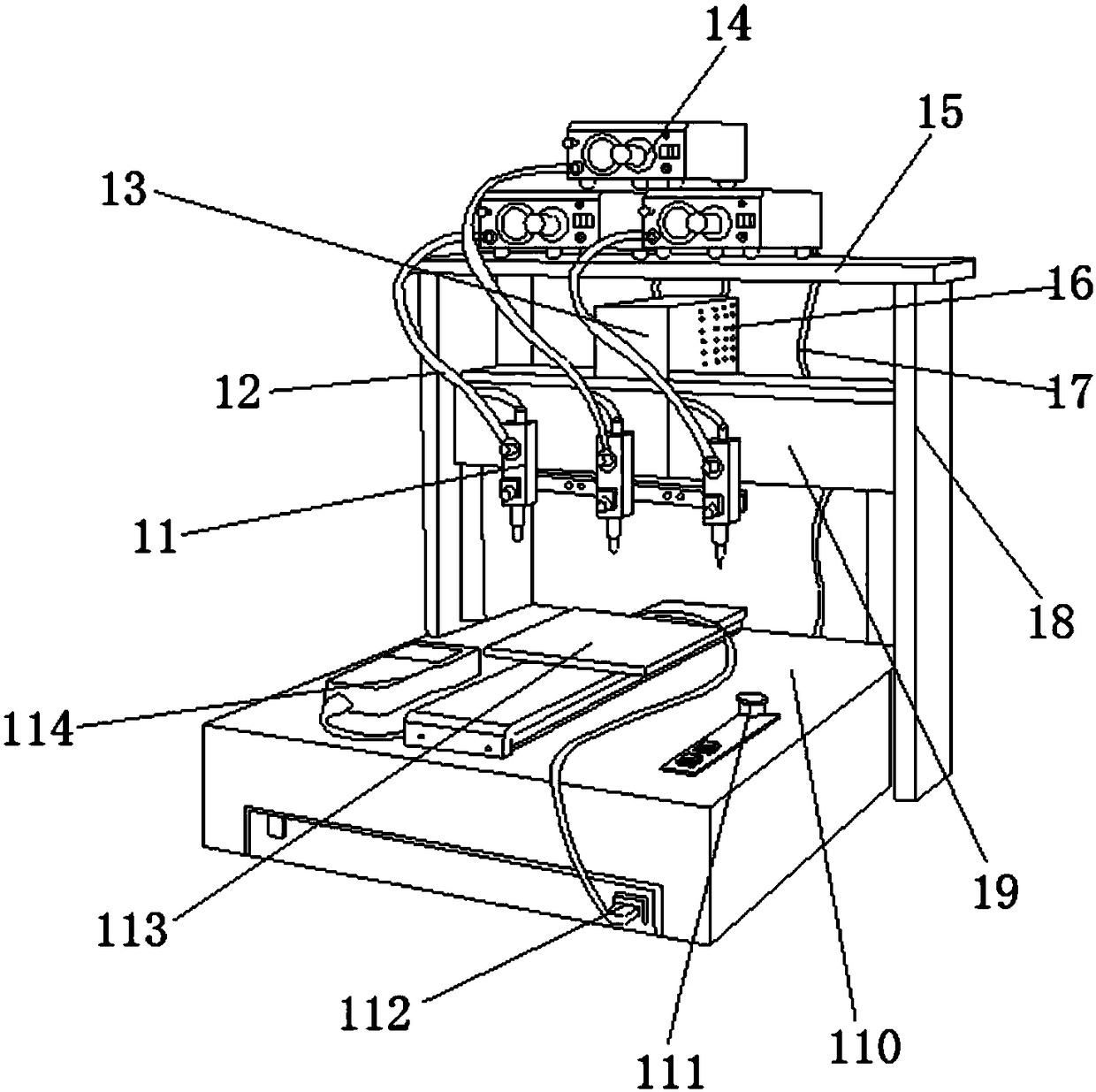

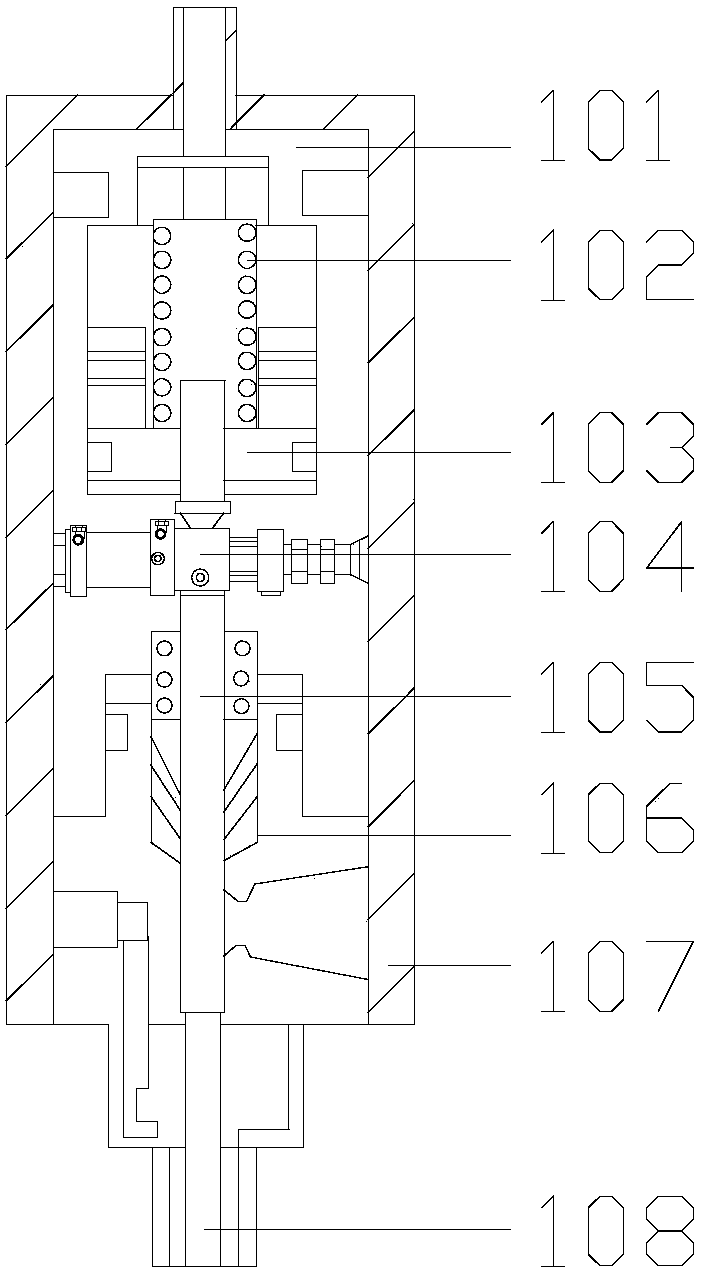

[0030] A process and system for packaging LEDs, comprising the following steps: S1: Apply silver glue on a bracket by dispensing equipment, and then bond chips to the silver glue to obtain LEDs; S2: Fix the LEDs with a crystal-bonding mechanism Crystallization operation, the specific principle is the existing technology, so it will not be repeated; then use a dryer to bake the LED at a temperature of 150°C for 2 hours; S3: Mold the LED for the first time with molding equipment, molding operation and principle It is an existing technology, so it will not be described in detail; S4: use fluorescent coating equipment to coat fluorescent film on LED, and the specific coating princ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com