Low-inertia rotor of permanent magnet motor

A permanent magnet motor and rotor technology, applied in the field of low inertia rotors, can solve the problems of reducing the effective utilization rate of the rotor core, affecting the performance of the permanent magnet motor, and discounting the effective length of the rotor core, so as to improve the effective utilization rate, Ensure the effect of effective length and small material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

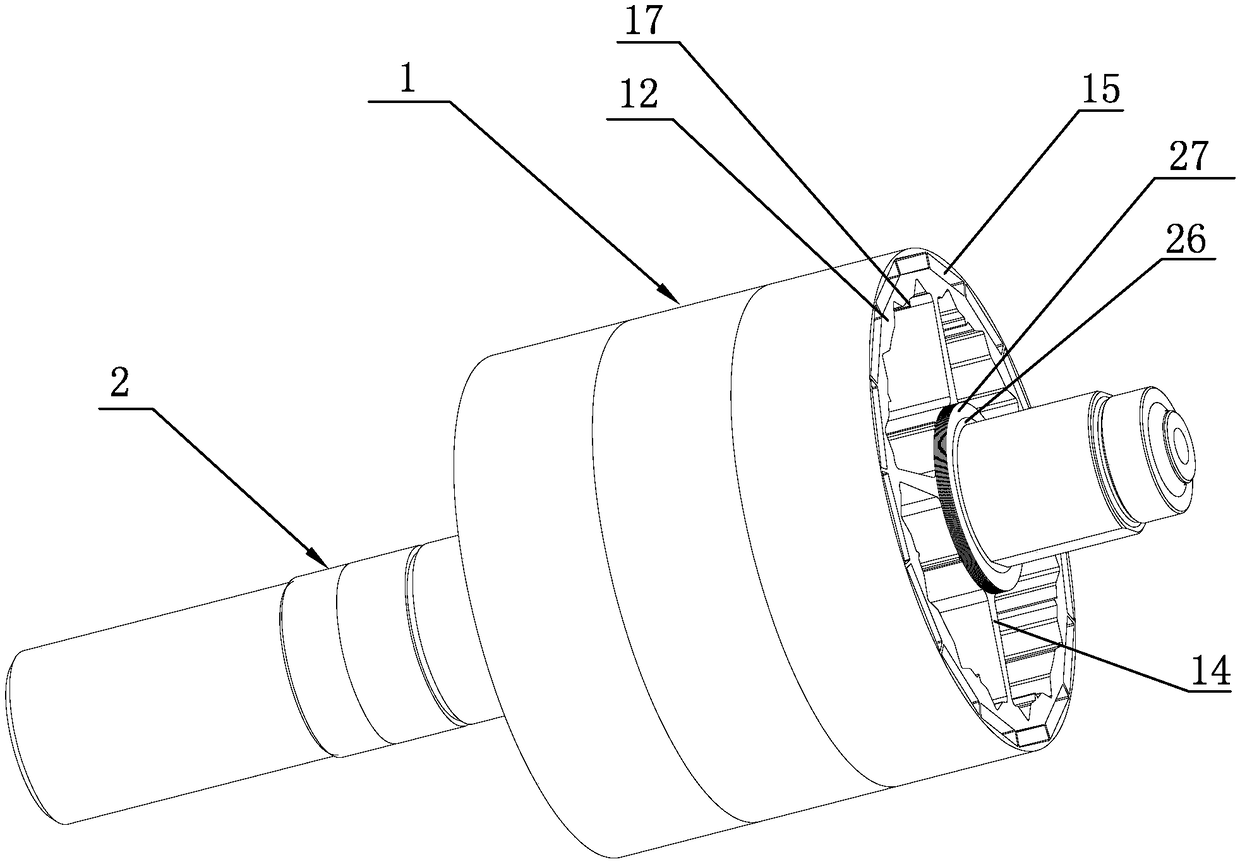

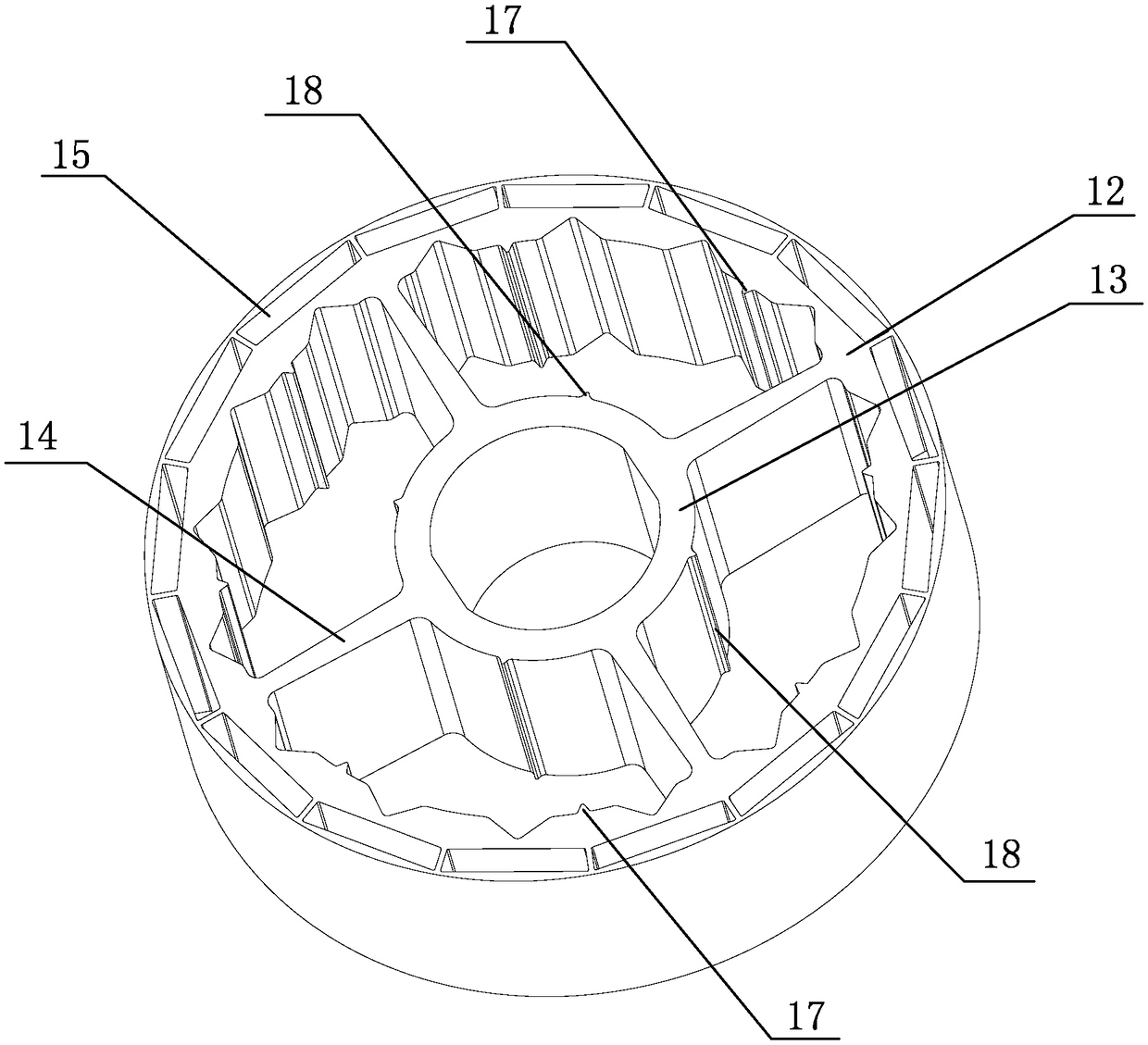

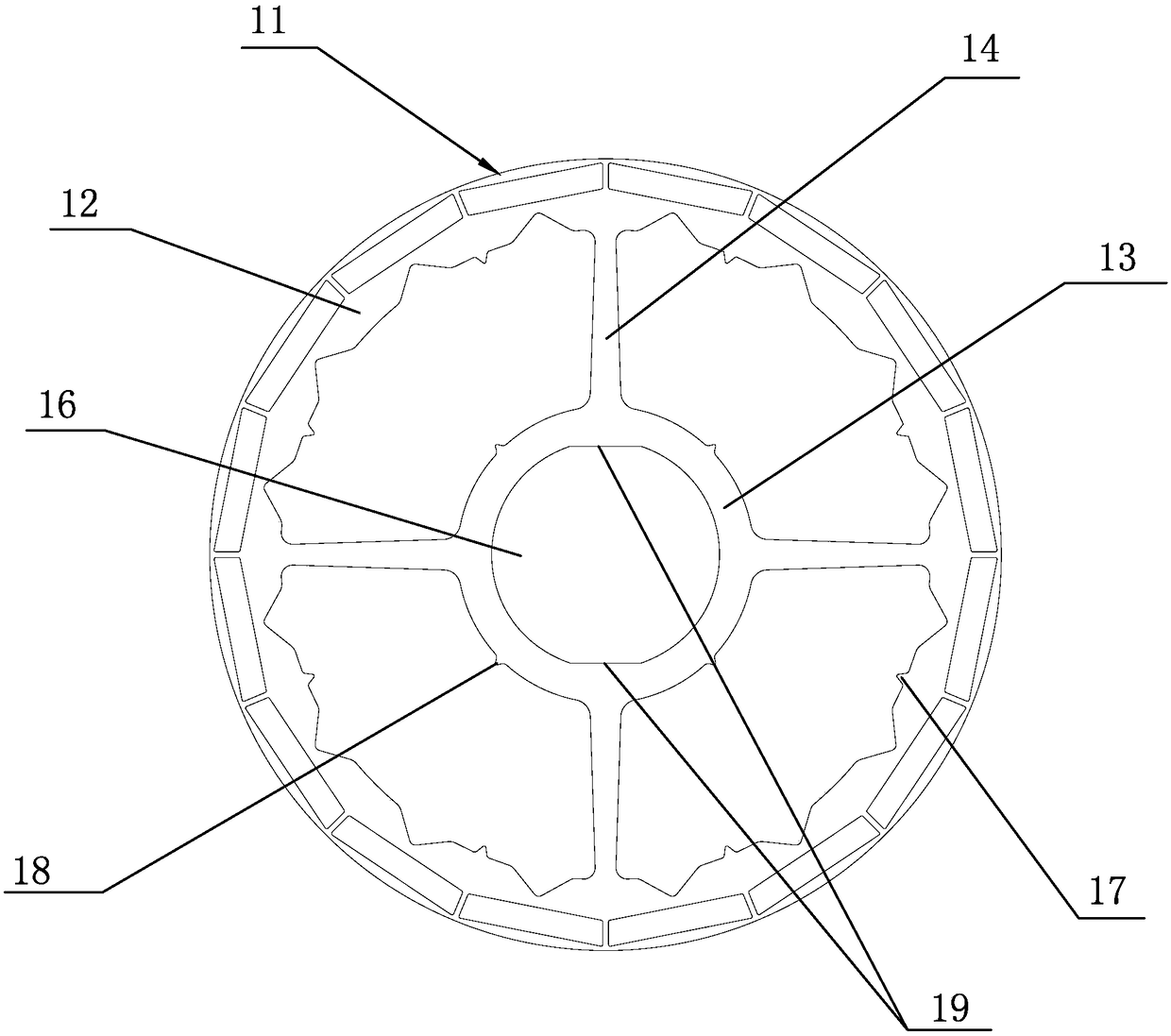

[0017] A low-inertia rotor of a permanent magnet motor proposed by the present invention, as shown in the figure, consists of three rotor core modules 1 connected in series on the rotating shaft 2 and press-fitted together with the rotating shaft 2. The rotor core module 1 consists of multiple Two rotor punches 11 are stacked and welded; the rotor punch 11 includes an outer ring 12, an inner ring 13, and four radial spokes 14 radially connecting the outer ring 12 and the inner ring 13, and the outer ring 12 is close to its outer circumference. There are 16 magnetic steel grooves 15 for embedded magnetic steel (not shown in the figure) evenly arranged along the circumferential direction at the position. The magnetic steel grooves 15 are embedded with magnetic steel. The inner ring 13 has a central inner hole 16. Eight inner peripheral welding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com