Reclaimed-material sole and production method of integrally-formed sole

A technology for recycling materials and shoe outsole, applied in shoe soles, footwear, footwear, etc., can solve the problems of high processing cost, environmental pollution, and many processes, and achieve the effect of simple process, excellent product quality, and comfortable wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the features, technical means and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

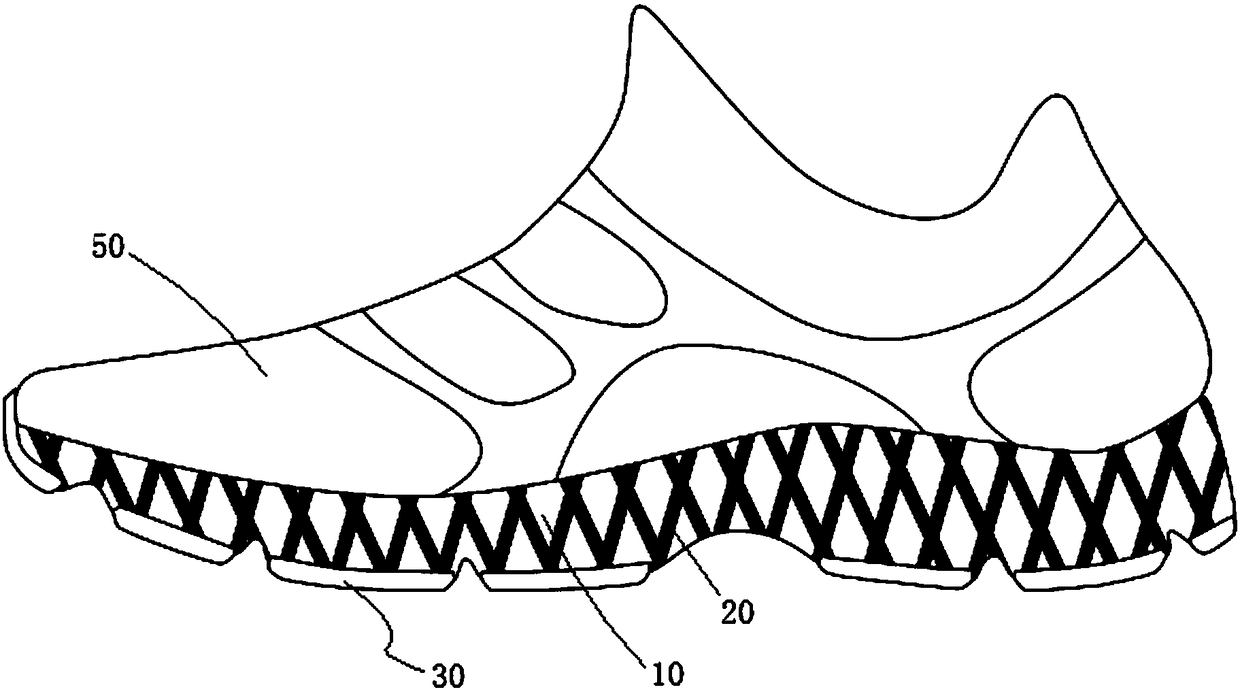

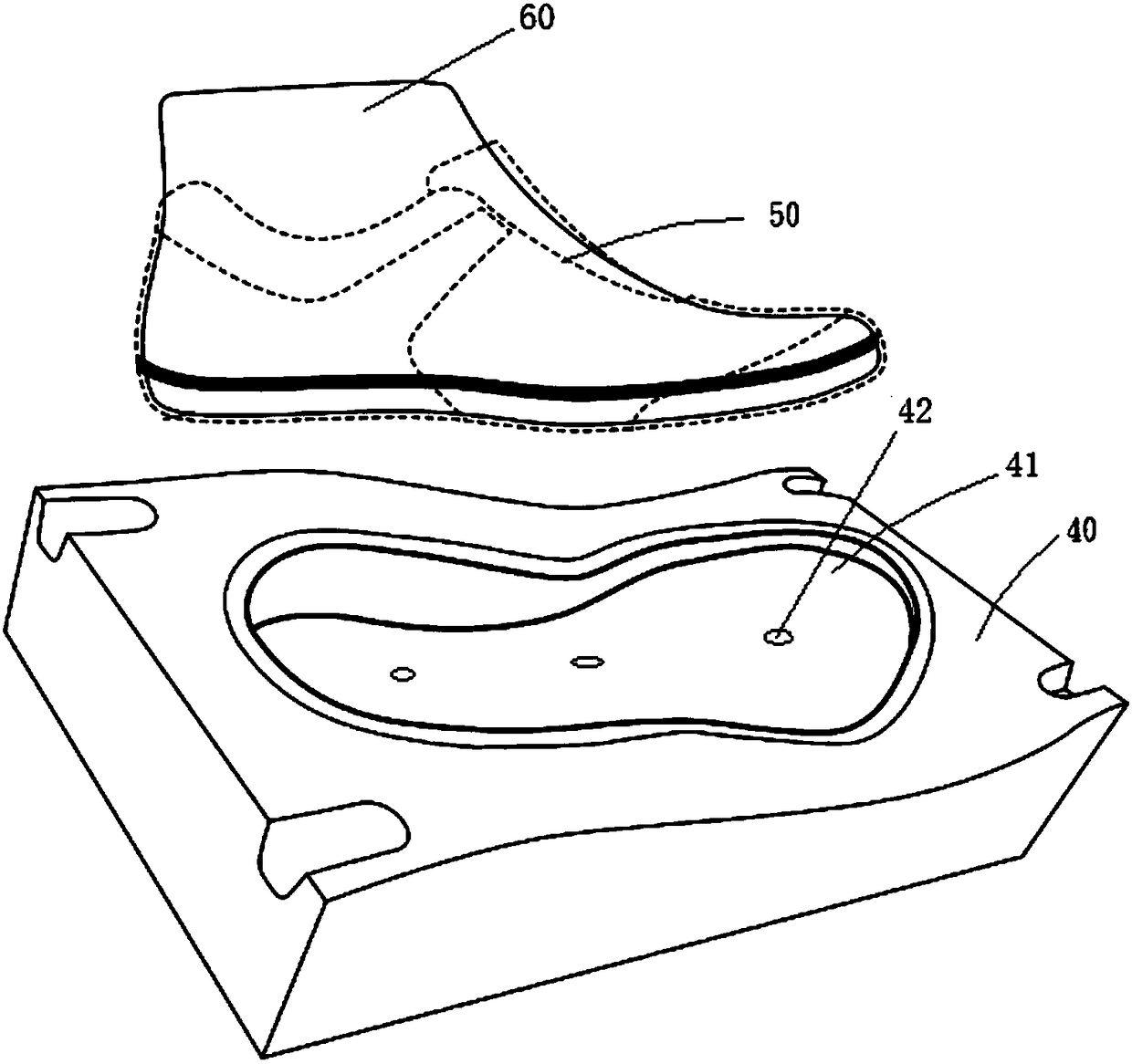

[0020] Such as figure 1 and figure 2 As shown, a recycled material sole of the present invention includes a shoe midsole 10, a shoe film 20 and a shoe outsole 30, the shoe film 20 is arranged between the shoe midsole 10 and the shoe outsole 30, and the periphery of the shoe film 20 Extended and attached to the side of the shoe midsole 10, the shoe film 20 is made of TPU film material, the shoe outsole 30 is made of rubber material, and the shoe midsole 10 includes the following substances in parts by weight: 25% to 45% EVA recycled material, 50%-70% polyurethane adhesive, 0.01%-0.05% catalyst and 1%-10% water. The EVA recycled material mainly comes from defective products or Leftovers can be recycled, and the catalyst is DMDEE (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com