Automatic stamping device for circular ring plate hardware

A technology for stamping processing and hardware parts, applied in metal processing equipment, storage devices, stripping devices, etc., can solve the problems of limited work efficiency, high stamping pressure, inconvenient movement and fixing, etc., so as to save manpower and material resources and improve production and processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

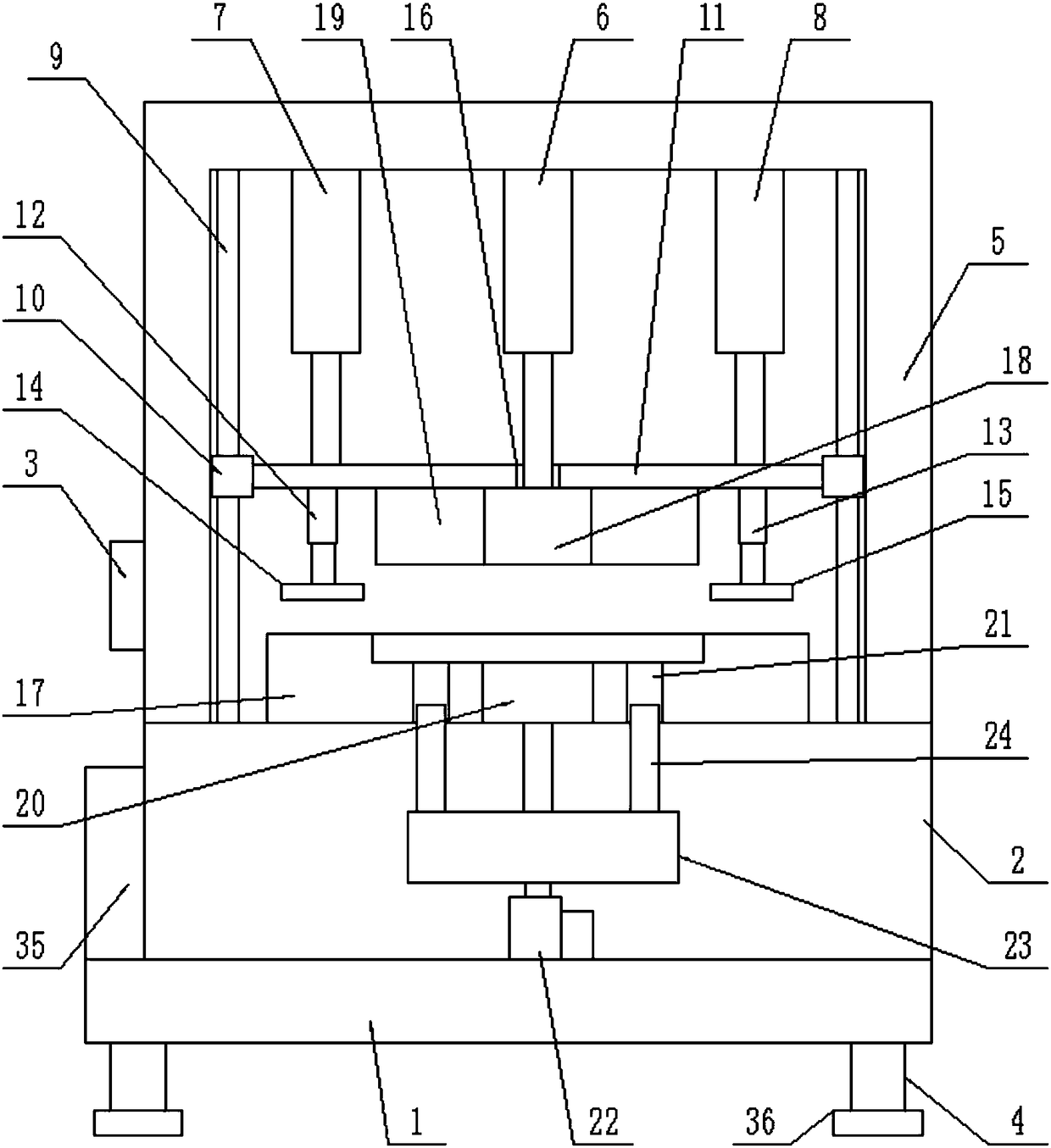

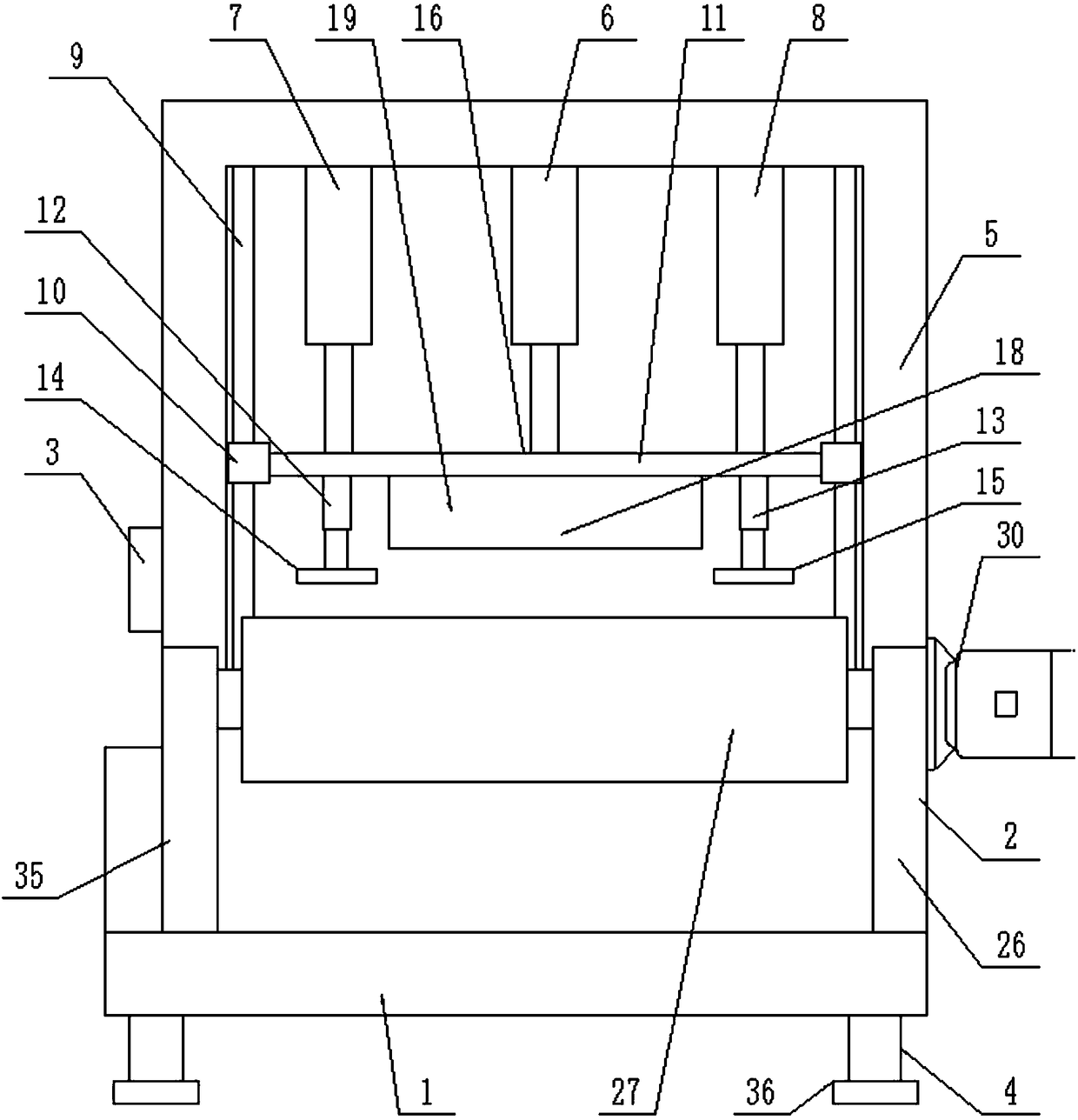

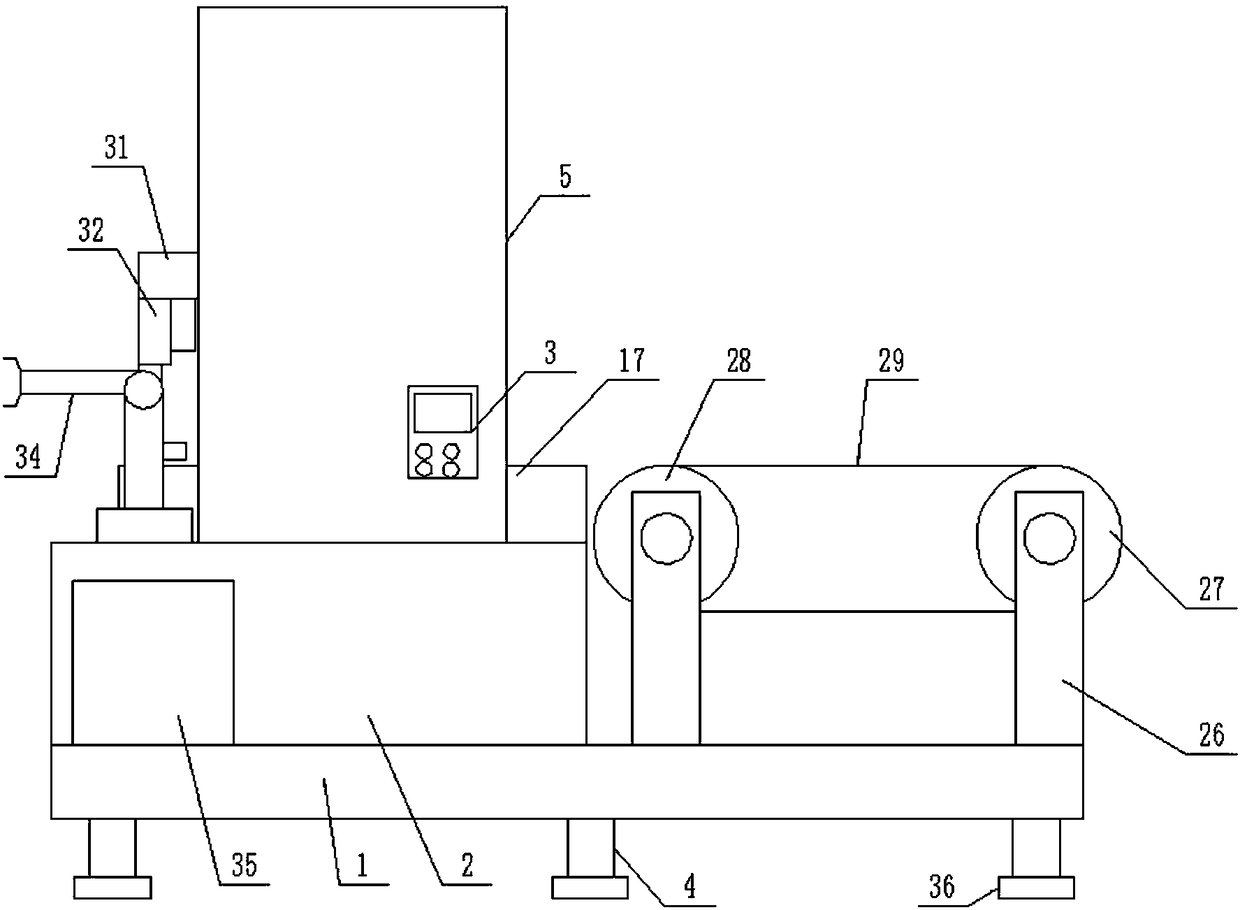

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 As shown, an automatic stamping processing device for circular plate hardware, including a base 1, a casing 2, a pressing mechanism, a stamping mechanism, a supporting mechanism, a conveying mechanism, a limit mechanism and a controller 3, the casing 2 is fixed on the base 1, the lower end of the base 1 is provided with a foot 4, and the press-down mechanism is composed of the gantry 5 fixed on the casing 2 and the second gantry 5 fixed at the center of the upper end of the gantry 5 A hydraulic cylinder 6, a second hydraulic cylinder 7 and a third hydraulic cylinder 8 fixed on the portal frame 5 and located on both sides of the first hydraulic cylinder 6, a slide bar 9 fixed on the inside of the portal frame 5, The slider 10 set in the slider 9, the left and right ends are connected with the slider 10 and the upper end is connected with the telescopic end of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap