Servo adjustable tool for brake disc machining

A technology of brake discs and cutting tools, which is applied to cutting tools for lathes, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to complete multiple processes, longer processing time, and low processing efficiency, and achieve exquisite structural design , Low manufacturing cost, high locking and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

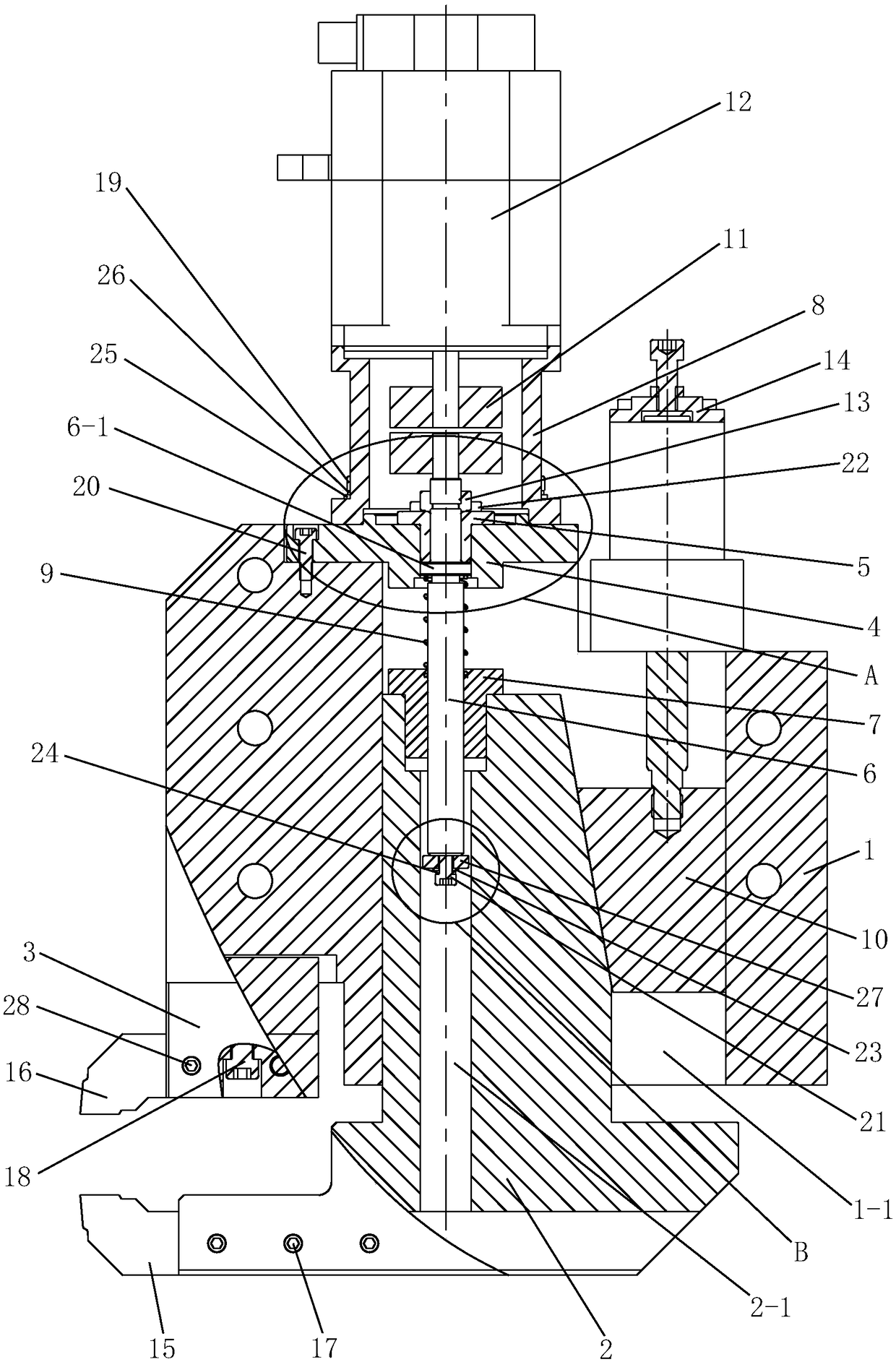

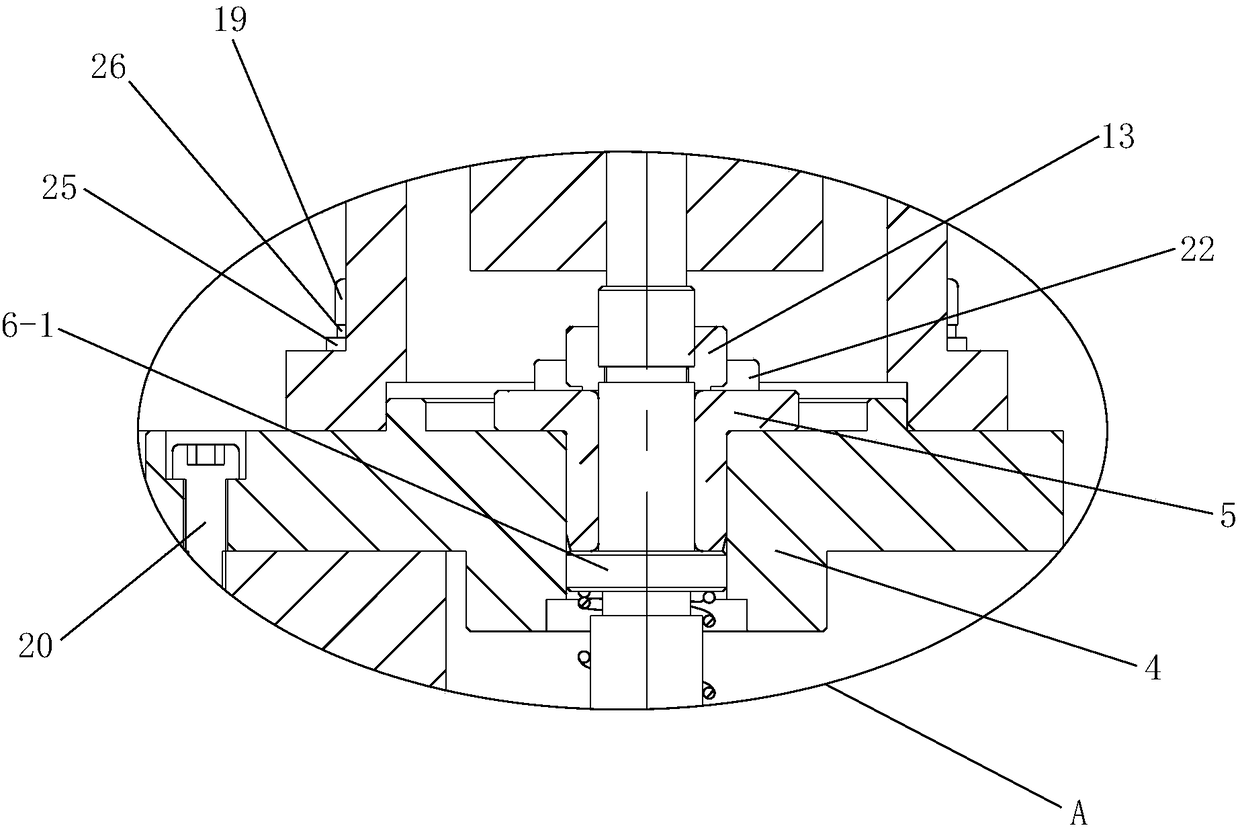

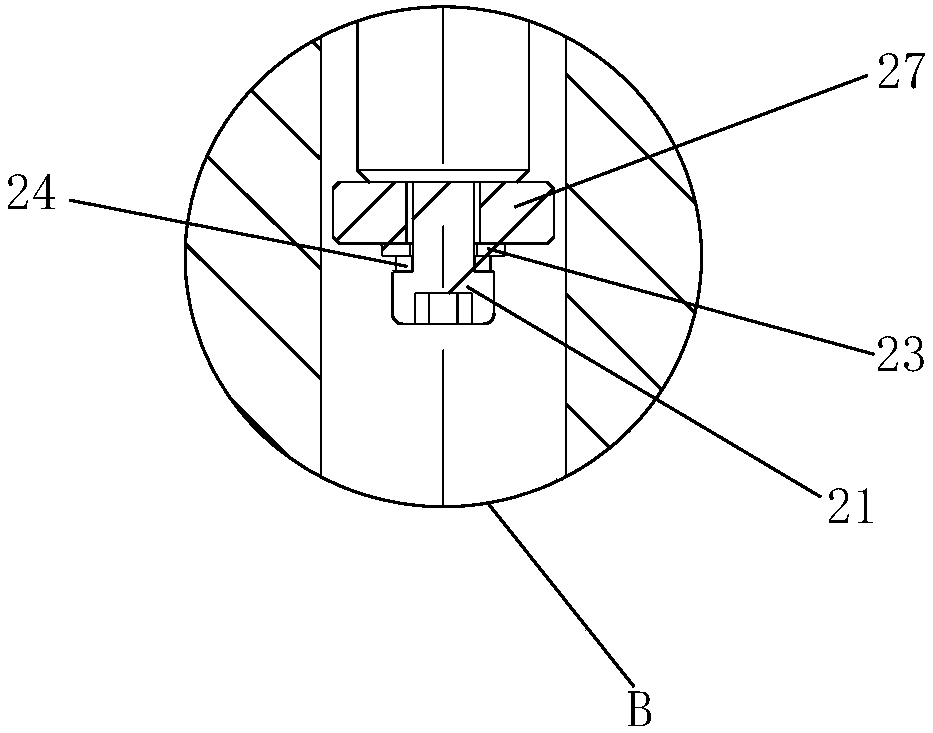

[0041] Such as Figure 1 to Figure 5 As shown, the present invention includes a knife seat body 1, an upper end face knife seat 3, a lower end face knife seat 2, a moving drive mechanism for driving the lower end face knife seat 2 to move up and down, and a moving drive mechanism installed on the knife seat body 1 and used for aligning the lower end face The compression limit mechanism of the end face knife seat 2 is pressed and limited. The upper end face knife seat 3 is fixedly installed on the bottom of the knife seat body 1, and the knife seat body 1 is provided with a mounting groove 1-1. The upper part of the end face knife seat 2 is arranged in the installation groove 1-1 and can move up and down in the installation groove 1-1, the lower part of the lower end face knife seat 2 is located outside the installation groove 1-1, and the upper end face knife seat 3 An upper turning tool 16 is installed on the top, and a lower turning tool 15 is installed on the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com