Slender hole deburring method based on tip-effect-induced pyrite reaction

A cutting-edge effect, slender hole technology, applied in the field of machining, can solve the problems of complex process, incomplete removal, difficult burr removal, etc., to achieve the effect of thorough burr removal, strong adaptability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

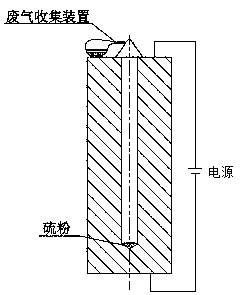

[0028] like figure 1 .

[0029] A kind of slender blind hole deburring method based on tip effect induced sulfur-iron reaction, it comprises the following steps:

[0030] The first step is to pour sulfur powder into the bottom of the elongated blind hole, and the amount of addition is appropriate to cover the burr area; the purity of the sulfur powder used is preferably above 99.99%; the elongated hole that needs to be cleaned of burrs should be vertical location, the same below;

[0031] The second step is to install the waste gas collection device on the slender orifice; the waste gas collection device can use an inverted conical glass cover, and the glass cover is connected with a balloon or an air bag with a built-in 10% concentration of sodium hydroxide absorption solution to collect the generated during the reaction. Exhaust gas and purification;

[0032] The third step is to energize the parts as a whole, and the energization voltage is DC 24-48V. Using the character...

Embodiment 2

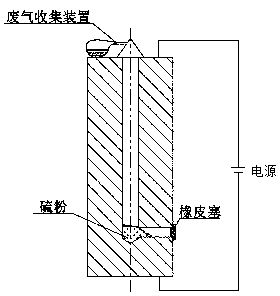

[0035] like figure 2 shown.

[0036] A method for deburring elongated vertically and horizontally through holes based on tip effect induced sulfur-iron reaction, which comprises the following steps:

[0037] The first step is to block the horizontal hole with a stopper (such as a rubber stopper or other non-chemically reactive soft plug) to prevent the sulfur powder from running out of the horizontal hole during the reaction, and then pour the sulfur powder into the elongated horizontal hole In the vertical hole, it is advisable to add the amount to cover the burr area; the purity of the sulfur powder used should preferably be above 99.99%

[0038] The second step is to install the waste gas collection device on the slender orifice; the waste gas collection device can use an inverted conical glass cover, and the glass cover is connected with a balloon or an air bag with a built-in 10% concentration of sodium hydroxide absorption solution to collect the generated during the r...

Embodiment 3

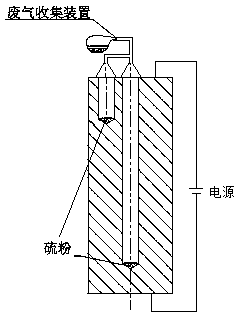

[0042] like image 3 .

[0043] A method for deburring two or more elongated blind holes based on tip effect induced sulfur-iron reaction, which comprises the following steps:

[0044] In the first step, pour the sulfur powder into the bottom of two or more elongated blind holes respectively, and the amount of addition is appropriate to cover the burr area; the purity of the sulfur powder used should preferably be above 99.99%; the burr needs to be cleaned in specific cases. The slender holes should be in a vertical position, or partly vertical, partly inclined; the horizontal slender blind holes should be divided into sections, after cleaning the vertical blind holes, turn them 90 degrees to make them vertical, and then repeat steps 1 to 4;

[0045] The second step is to install an exhaust gas collection device at the slender orifice; the exhaust gas collection device can use an inverted conical glass cover, and then use a balloon or air bag with a built-in 10% concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com