Grinding process of plate roller

A version roller and process technology, which is applied in the field of version roller grinding technology, can solve the problems of low processing accuracy and laborious grinding of version rollers, and achieve the effects of high processing accuracy, time-saving and labor-saving grinding, and safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below by means of specific embodiments:

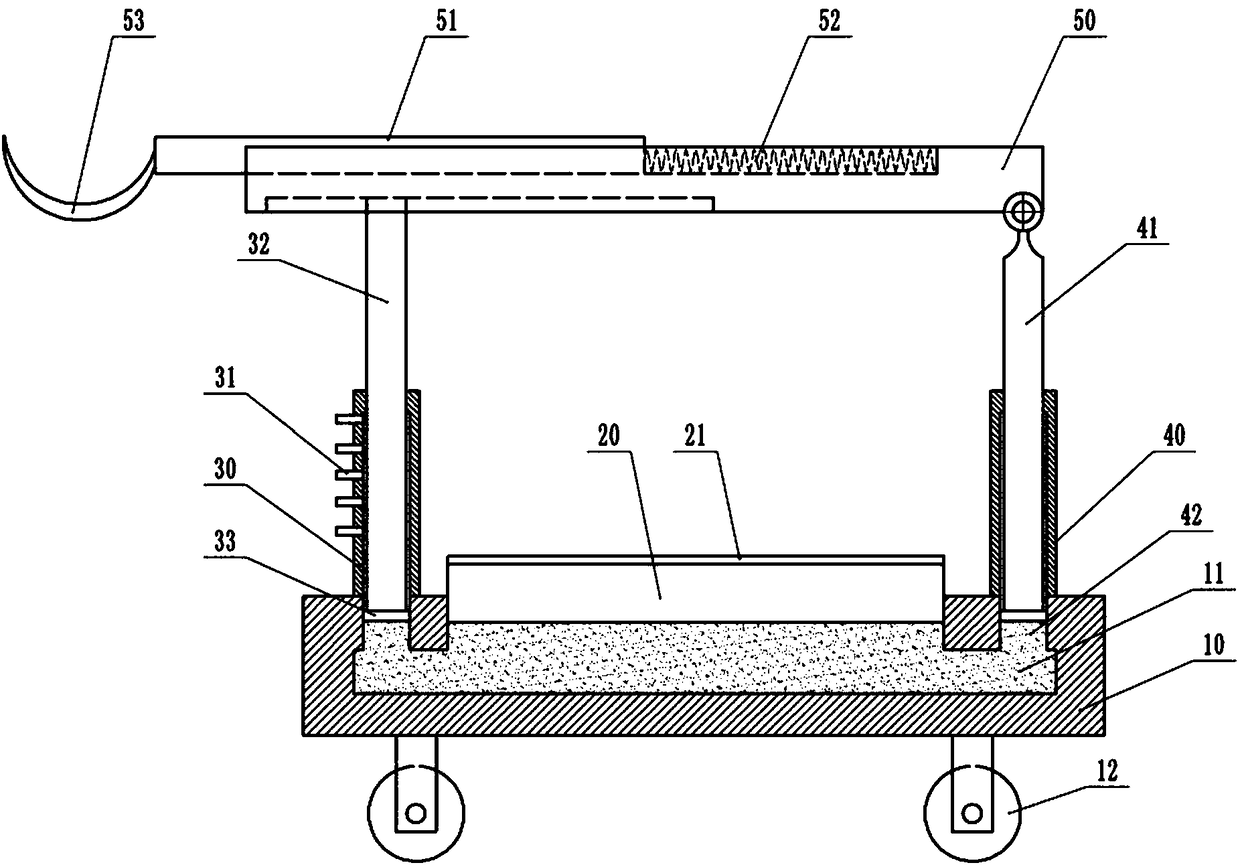

[0032] The reference signs in the accompanying drawings of the description include: base 10, cavity 11, roller 12, pressure block 20, pedal 21, front lower strut 30, limit post 31, front upper strut 32, limit block 33 , the rear lower strut 40, the rear upper strut 41, the connection cavity 42, the support plate 50, the connection plate 51, the reset elastic member 52, and the support frame 53.

[0033] A kind of plate roller polishing process, comprises the following steps:

[0034] (1) Belt installation: Check whether the grinding wheel on the CNC grinding machine is intact, and if it is not intact, replace the intact grinding wheel; increase the coolant of the CNC grinding machine, and insert the belt into the inner hole of the plate roller; the belt can avoid that when the CNC machine tool is running, Resonance phenomenon occurs in the inner hole of the plate roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com