Manufacturing method for windscreen wiper supporting base

A kind of manufacturing method, technology of wiper blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

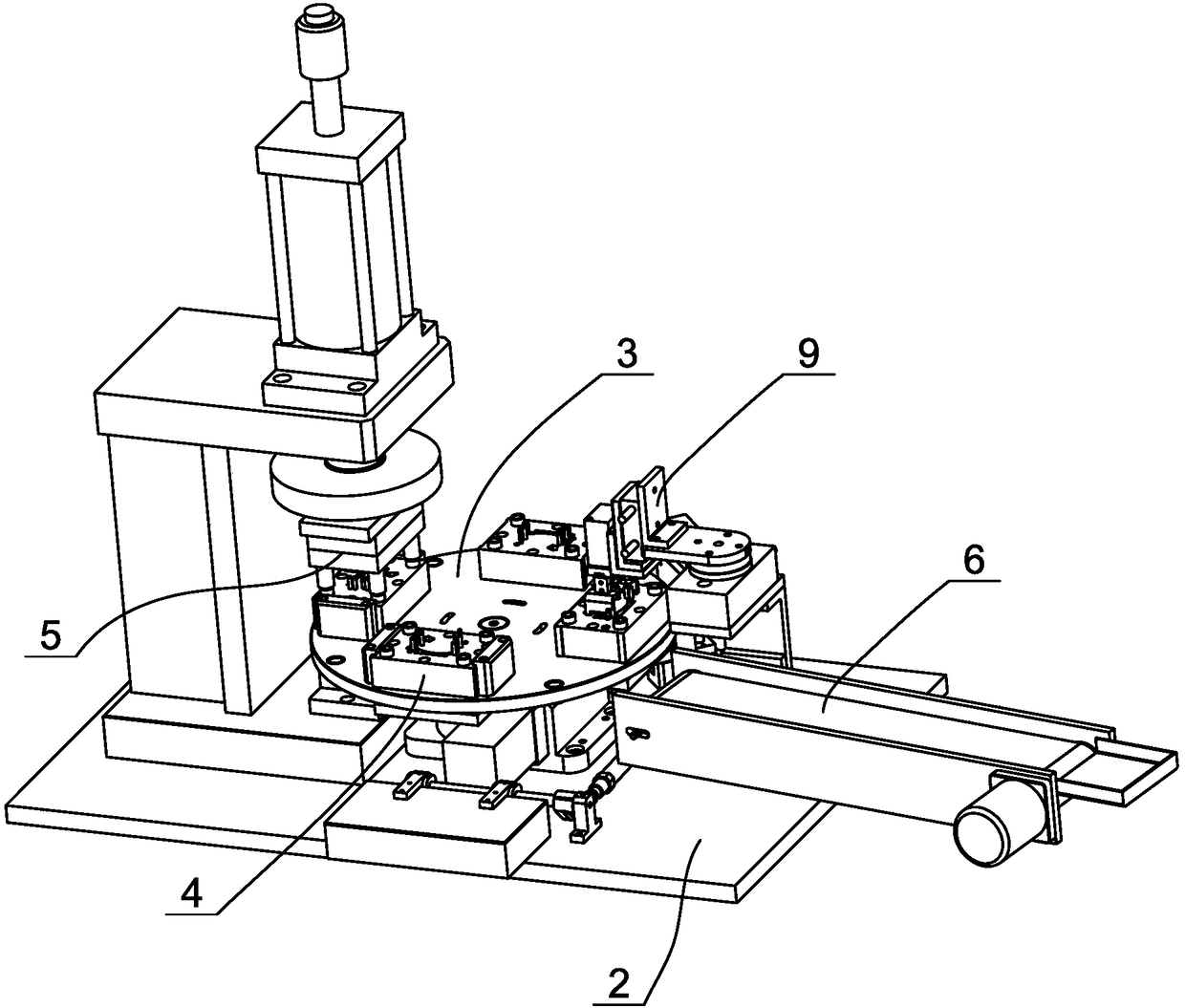

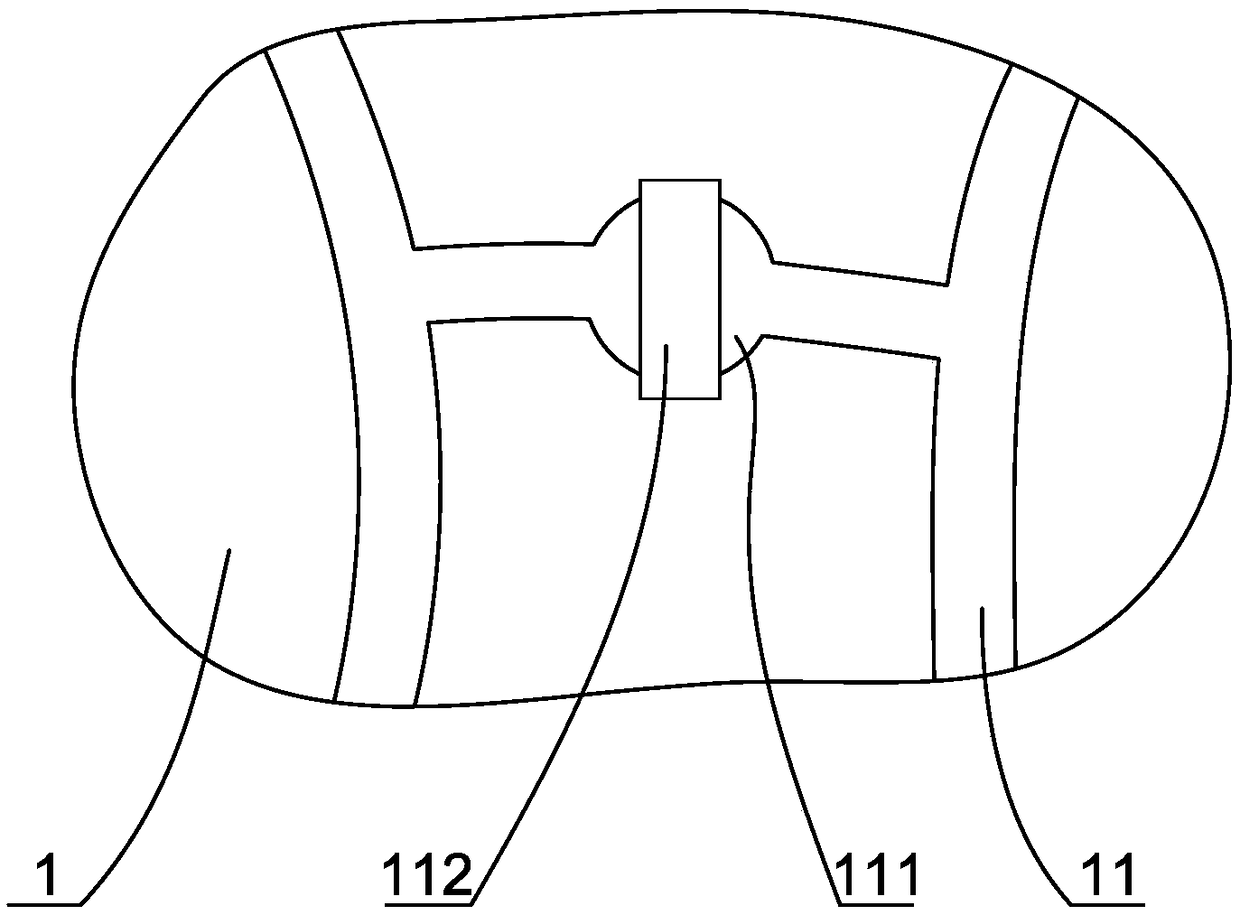

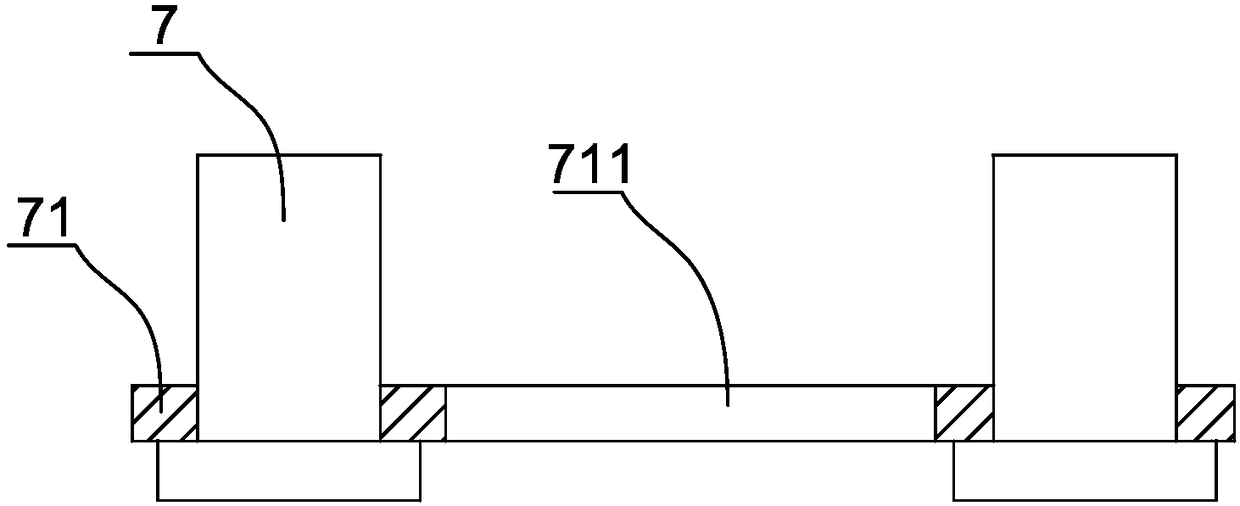

[0031] Embodiment 1: A manufacturing method of a wiper support, the wiper support includes a plastic support, a conductive return bar embedded in the plastic support, and an elastic contact piece riveted together with the return bar, specifically as follows step:

[0032] a. Install the support forming mold used to form the plastic support on the injection molding machine, and put a reflow bar assembly as an insert into the support forming mold in the split state. The backflow strip assembly includes several backflow strips, and an integral connecting portion is provided between adjacent backflow strips, thereby forming a whole-structure backflow strip assembly. Of course, the backflow bar assembly can be manufactured by stamping or precision casting;

[0033] b. Clamp the support forming mold and start injection molding, so as to obtain a semi-finished product including the plastic support and the return bar assembly, and the return bar assembly is embedded in the plastic su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com