Paperboard impressing and punching device

A punching device and indentation technology, applied in paper/cardboard containers, packaging, papermaking, etc., can solve problems such as inconvenient operation, achieve convenient operation, high degree of automation, and eliminate the need to carry cardboard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

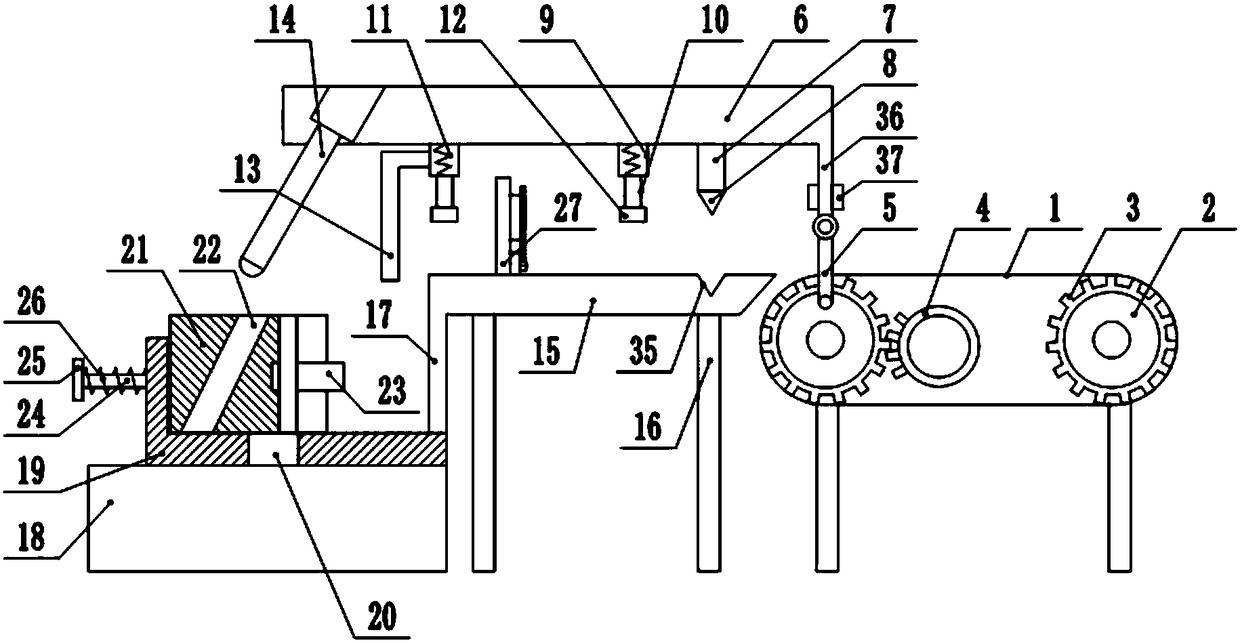

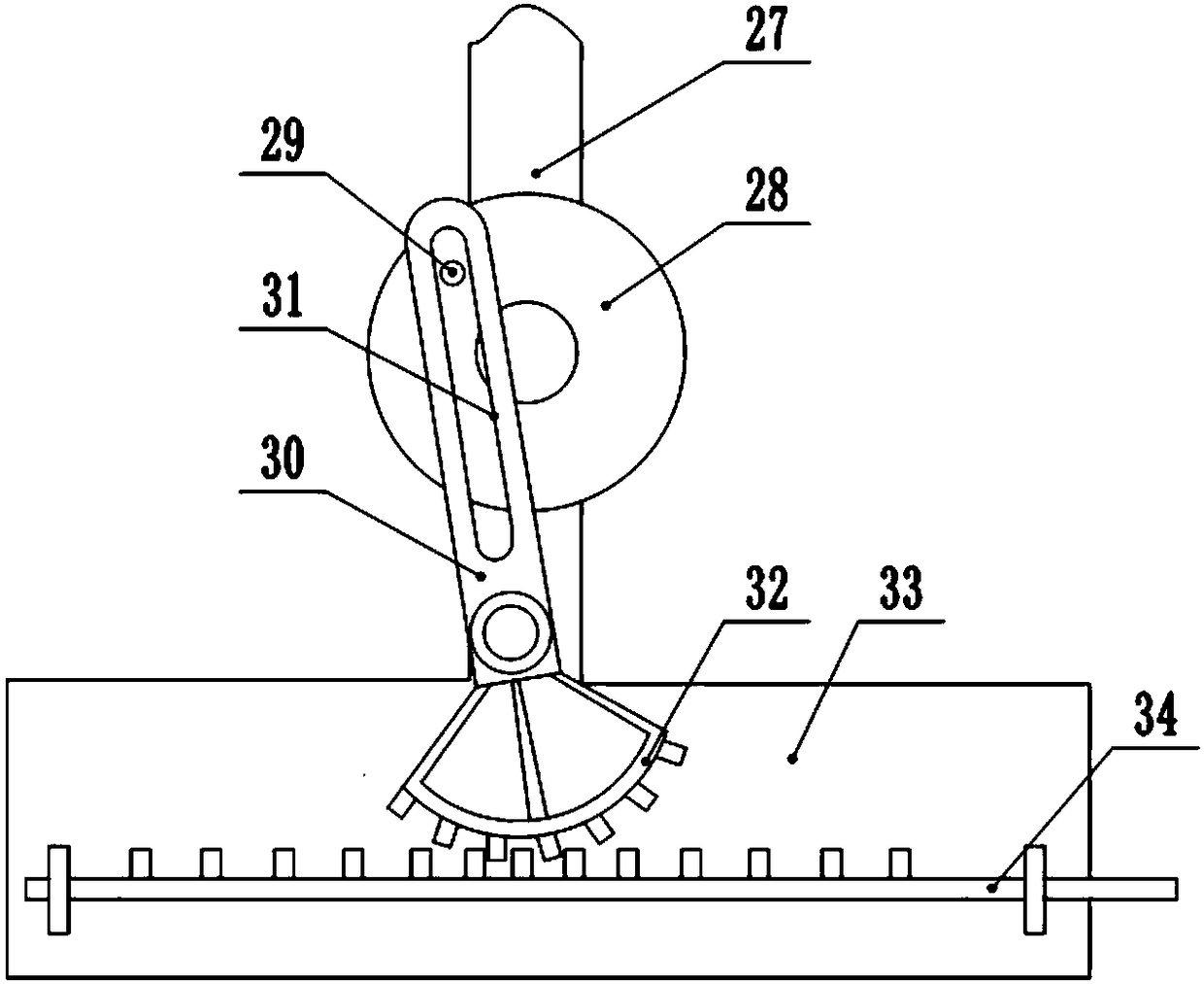

[0017] The reference signs in the accompanying drawings include: conveyor belt 1, transmission wheel 2, teeth 3, notch gear 4, drive rod 5, console 6, cutter rod 7, first cutter head 8, first rod 9, second rod 10. Telescopic spring 11, indentation head 12, first platen 13, slide bar 14, table top 15, bracket 16, second platen 17, punching table 18, punching plate 19, insertion slot 20, punching seat 21, Insertion hole 22, second cutter head 23, pull rod 24, fixed block 25, support spring 26, support rod 27, turntable 28, bump 29, swing plate 30, strip hole 31, sector gear 32, support plate 33, tooth Bar 34, cutting groove 35, connecting rod 36, positioning bar 37.

[0018] Such as figure 1 , figure 2 Shown: an indentation punching device for cardboard, including a frame and a conveying mechanism. The conveying mechanism includes a conveying belt 1 and a conveying whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com