Screen printing plate used for crystal silicon solar cell step-by-step printing technology

A technology of solar cells and crystalline silicon, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of reducing height and width, affecting the collection and loss of sub-grid current, and reducing the impact and reduction of sub-grid lines Disconnect, increase the effect of penetrating ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

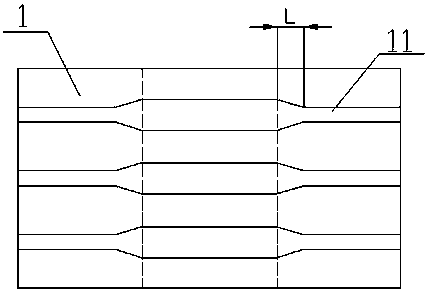

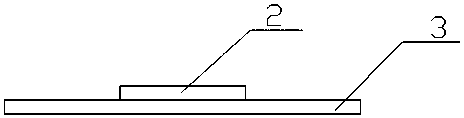

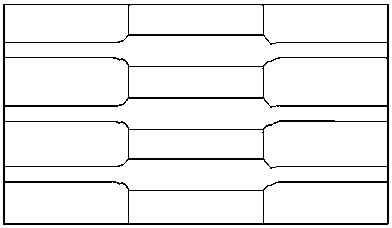

[0016] Such as Figure 1~3 As shown, a screen for step-by-step printing process of crystalline silicon solar cells, including a main grid screen and a sub-grid screen 1, corresponding to a main grid line 2 on the main grid screen, and a main grid line 2 on the sub-grid screen There are auxiliary grid lines 11 corresponding to the plate 1, and the width of the auxiliary grid lines 11 on the auxiliary grid plate 1 is at a distance from the edge of the corresponding position of the main grid line 2 on the main grid plate ( figure 1 The positions of the two dotted lines in the center gradually widen at a certain distance L from the edge of the main grid line, and the width reaches the maximum at the overlap with the position of the main grid line 2.

[0017] The width of the sub-grid line 11 on the sub-grid screen plate 1 is gradually widened at a distance of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com