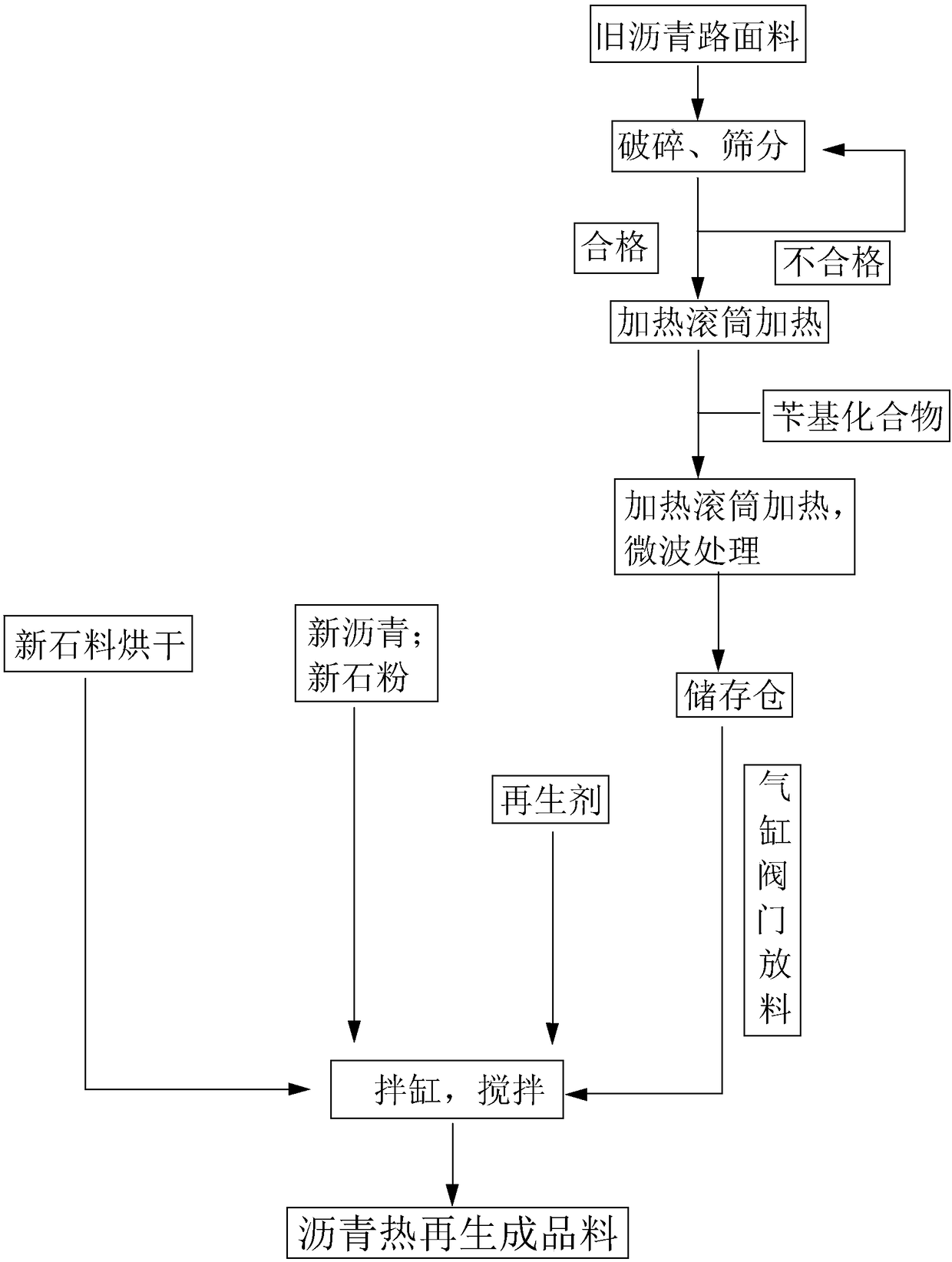

Asphalt thermal regeneration production process

A production process and thermal regeneration technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of asphaltene condensation, poor asphaltene compatibility, poor asphaltene dispersion effect, etc., to reduce pollution and improve compatibility. Sexuality, the effect of inhibiting volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] S1: Collect old asphalt road fabrics and transport them to the mixing site for use;

[0040] S2: Use the loader to send the collected old asphalt road fabric to the hopper of the crushing and screening equipment. After being crushed by the primary crusher, it is sent to the vibrating screen for screening and classification. The particles smaller than 10mm are directly collected, and the particles larger than 10mm are directly collected. The particles are sent to the secondary crusher through the conveyor belt for crushing, and then sent to the vibrating screen for screening and classification, so that the larger particles circulate between the crusher and the vibrating screen until their size is less than 10mm;

[0041] S3: Send 800 parts of the old asphalt road fabric with a size less than 10mm selected from S2 in parts by weight into the heating drum, and heat the materials in the heating drum by burning fuel oil; in order to make the fuel burn more fully, the fuel oil...

Embodiment 2

[0048] S1: Collect old asphalt road fabrics and transport them to the mixing site for use;

[0049] S2: Use the loader to send the collected old asphalt road fabric to the hopper of the crushing and screening equipment. After being crushed by the primary crusher, it is sent to the vibrating screen for screening and classification. The particles smaller than 10mm are directly collected, and the particles larger than 10mm are directly collected. The particles are sent to the secondary crusher through the conveyor belt for crushing, and then sent to the vibrating screen for screening and classification, so that the larger particles circulate between the crusher and the vibrating screen until their size is less than 10mm;

[0050]S3: Send 750 parts of the old asphalt road fabric with a specification less than 10mm selected from S2 in parts by weight into the heating drum, and heat the materials in the heating drum by burning fuel oil; in order to make the fuel oil burn more fully, ...

Embodiment 3

[0057] S1: Collect old asphalt road fabrics and transport them to the mixing site for use;

[0058] S2: Use the loader to send the collected old asphalt road fabric to the hopper of the crushing and screening equipment. After being crushed by the primary crusher, it is sent to the vibrating screen for screening and classification. The particles smaller than 10mm are directly collected, and the particles larger than 10mm are directly collected. The particles are sent to the secondary crusher through the conveyor belt for crushing, and then sent to the vibrating screen for screening and classification, so that the larger particles circulate between the crusher and the vibrating screen until their size is less than 10mm;

[0059] S3: Send 900 parts of the old asphalt road fabric with a specification less than 10mm selected from S2 in parts by weight into the heating drum, and heat the materials in the heating drum by burning fuel oil; in order to make the fuel burn more fully, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com