Anti-peeping film

An anti-peep film and anti-peep technology, applied in the field of film materials, can solve the problem of urgent need for development of anti-peep tempered film, and achieve the effect of protecting information security and protecting electronic screens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

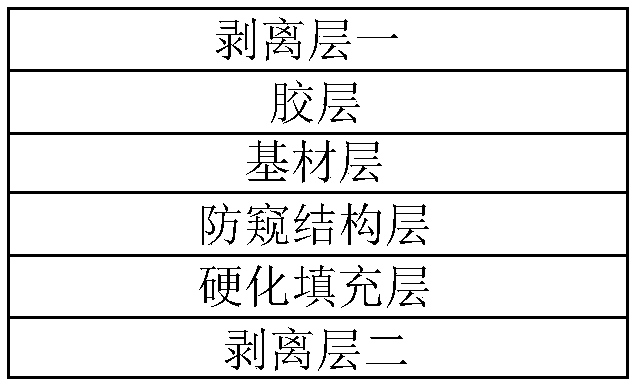

Image

Examples

Embodiment 1

[0026] A PET film with a thickness of 50 μm is used as the substrate layer;

[0027] Coating silica gel on the surface of the substrate layer, the silica gel is added with a color paste with a mass content of 0.1%, forming an adhesive layer with a thickness of 50 μm, and the peeling force between the adhesive layer and the substrate layer is 3.2gf / 25mm ; A PET film with a thickness of 50 μm is coated on the surface of the adhesive layer to form a peeling layer one;

[0028] Apply UV transfer glue on the other surface of the substrate layer for photocuring to form a structural layer with a thickness of 60 μm and a regular arrangement of a plurality of isosceles trapezoidal protrusions. The acute angle of the isosceles trapezoid is 84°, and two adjacent The interval between each trapezoidal protrusion is 16 μm, and the anti-peeping structure layer is obtained, and the shrinkage rate of the anti-peeping structure layer is 3.2%.

[0029] Coat PRD-3000 glue (epoxy modified acrylat...

Embodiment 2

[0035] A PET film with a thickness of 50 μm is used as the substrate layer;

[0036] Coating silica gel on the surface of the substrate, adding a color paste with a mass content of 0.15% to the silica gel to form an adhesive layer with a thickness of 30 μm, and the peeling force between the adhesive layer and the substrate layer is 3.0gf / 25mm; A PET film with a thickness of 50 μm is coated on the surface of the adhesive layer to form a peeling layer one;

[0037] Apply UV transfer glue on the other surface of the substrate layer for photocuring to form a structural layer with a thickness of 72 μm and a regular arrangement of isosceles trapezoidal protrusions. The acute angle of the isosceles trapezoid is 84°, and two adjacent The interval between each trapezoidal protrusion is 16 μm, and the anti-peeping structure layer is obtained, and the shrinkage rate of the anti-peeping structure layer is 3.2%.

[0038] Coat PRD-3000 glue (epoxy modified acrylate, low shrinkage rate) wit...

Embodiment 3

[0044] A PET film with a thickness of 50 μm is used as the substrate layer;

[0045] Coating silica gel on the surface of the substrate, adding a color paste with a mass content of 0.15% to the silica gel to form an adhesive layer with a thickness of 30 μm, and the peeling force between the adhesive layer and the substrate layer is 3.0gf / 25mm; A PET film with a thickness of 50 μm is coated on the surface of the adhesive layer to form a peeling layer one;

[0046] Apply UV transfer glue on the other surface of the substrate layer for photocuring to form a structural layer with a thickness of 72 μm and a regular arrangement of isosceles trapezoidal protrusions. The acute angle of the isosceles trapezoid is 85°, and two adjacent The interval between each trapezoidal protrusion is 20 μm, and the anti-peeping structural layer is obtained, and the shrinkage rate of the anti-peeping structural layer is 2.2%.

[0047] Coat PRD-3000 glue (epoxy-modified acrylate, low shrinkage) with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com