3D printing wall unit, 3D printing wall system and manufacturing method thereof

A 3D printing and wall unit technology, applied in the field of architectural 3D printing, can solve problems such as long construction period, high cost, and difficulty in ensuring construction quality, and achieve the effects of improving construction efficiency, beautiful appearance, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

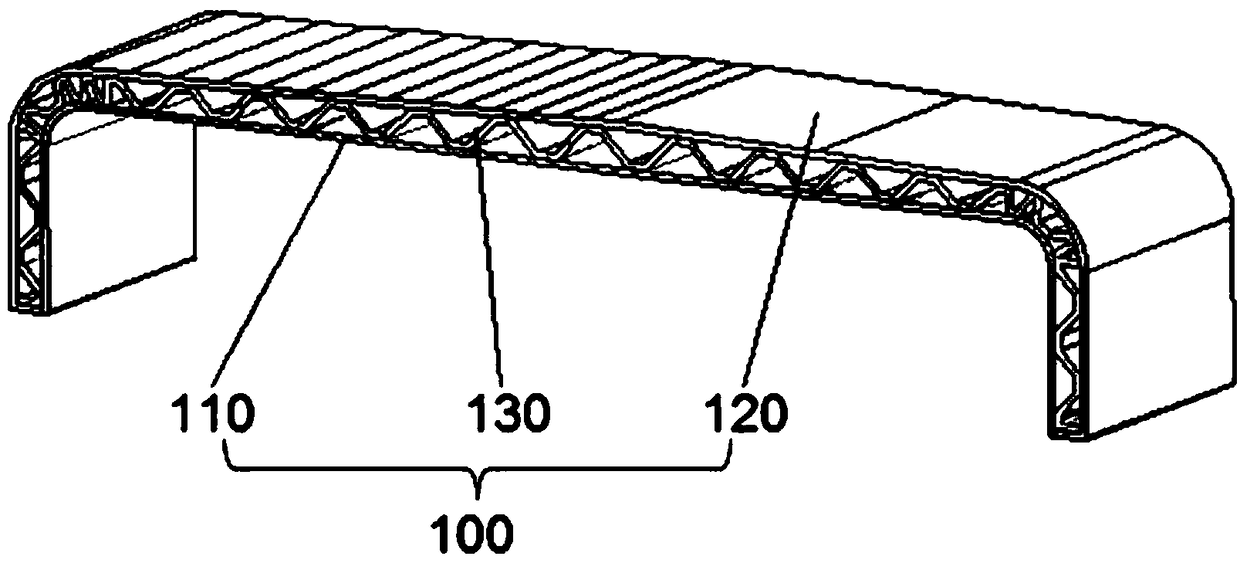

[0045] Such as figure 1 and 2 As shown, this embodiment provides a 3D printing wall unit, including a first wall 100, specifically:

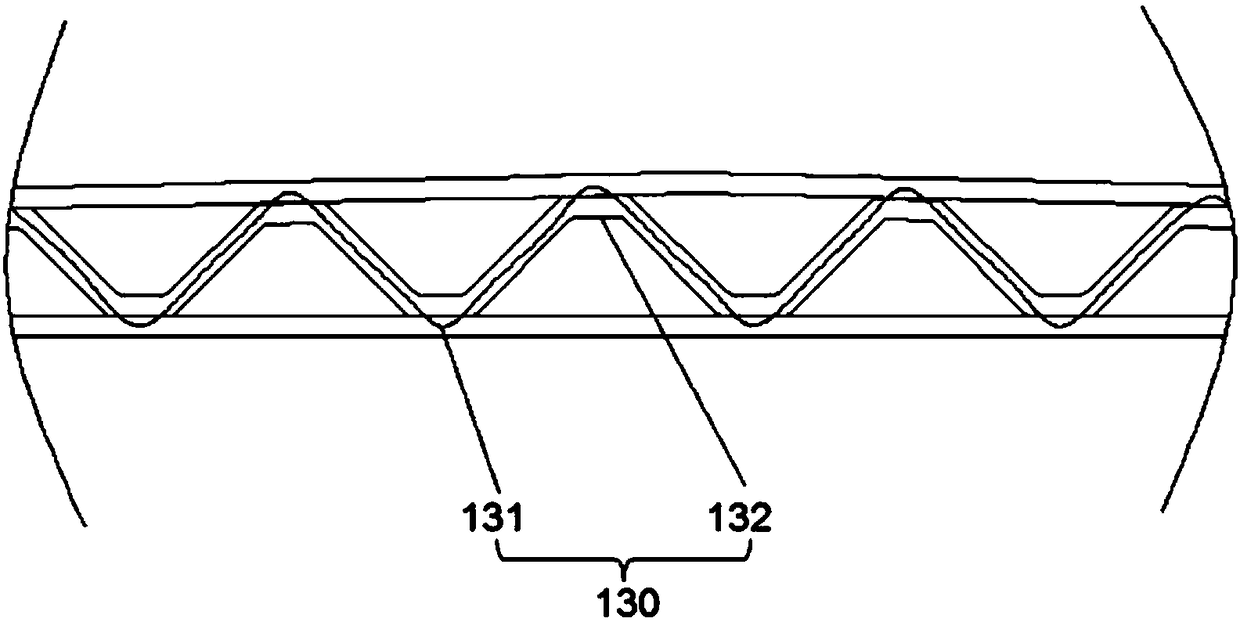

[0046] The first wall body 100 includes an inner wall panel 110, an outer wall panel 120 and a reinforcing rib 130;

[0047] The outer wall panel 120 is arranged on the outer side of the inner wall panel 110, and the ends of the inner wall panel 110 and the outer wall panel 120 are connected, so that the inner wall panel 110 and the outer wall panel 120 are surrounded by a cavity, and the reinforcing rib 130 is arranged in the cavity, and the ribs 130 are respectively connected to the inner wall panel 110 and the outer wall panel 120;

[0048] Both the inner wall panel 110 and the outer wall panel 120 have U-shaped cross-sectional shapes along the horizontal direction.

[0049] The 3D printed wall unit includes a first wall 100, which is an integrated structure printed by a 3D printer. The integrated structural design is conducive to improvin...

Embodiment 2

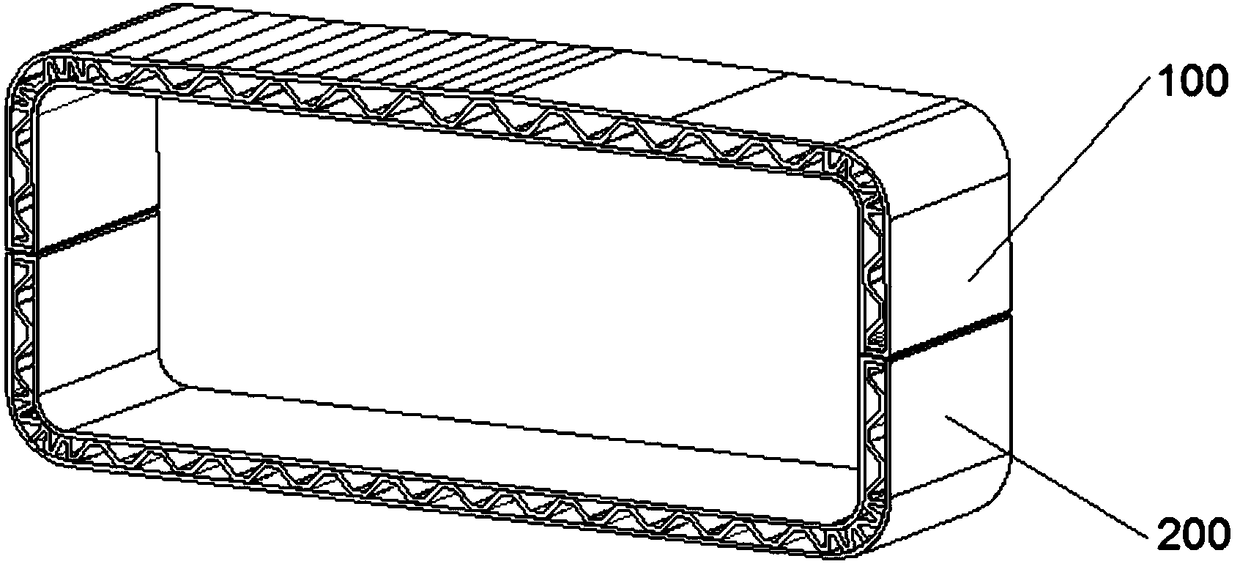

[0058] Such as image 3 As shown, this embodiment provides a 3D printing wall system, including the 3D printing wall unit of Embodiment 1 and the second wall 200, specifically:

[0059] The structure of the second wall body 200 is the same as that of the first wall body 100 , and two free ends of the second wall body 200 are respectively connected with two free ends of the first wall body 100 to form a frame structure.

[0060] Since the height of the bus stop is generally high, in order to facilitate installation and transportation, and improve the stability of the structure, the first wall 100 and the second wall 200 are assembled on site in the form of splicing and splicing. The first wall 100 The structure is the same as that of the second wall 200. Using 3D printing, the printing and manufacturing of the first wall 100 and the second wall 200 can be quickly realized. During printing, the U-shaped first wall 100 is set horizontally. The second wall body 200 is arranged ve...

Embodiment 3

[0065] This embodiment provides a manufacturing method for manufacturing the 3D printing wall system as in Embodiment 2, specifically, including:

[0066] Use a 3D printer to print the first wall;

[0067] Use a 3D printer to print the second wall;

[0068] The two free ends of the second wall are respectively connected with the two free ends of the first wall to obtain a 3D printed wall system.

[0069] Specifically, the structure of the second wall is the same as that of the first wall, which can realize fast printing and mass production. Printing the first wall with a 3D printer includes:

[0070] Braided reinforcement;

[0071] Use the 3D printer to print the interior wall panels and exterior wall panels in the vertical direction to realize the printing of U-shaped interior wall panels and exterior wall panels from bottom to top;

[0072] After the interior wall panels and exterior wall panels are printed to a certain height, place the braided reinforcement ribs on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com