Reflective stripe three-dimensional shape measuring method based on multi-field view splice

A technology of three-dimensional surface shape and measurement method, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of limited field of view, inability to fully measure and accurately measure the three-dimensional shape of the reflective workpiece surface, and inaccurate phase measurement. Achieve the effects of avoiding low measurement accuracy, fast three-dimensional surface measurement, and solving matching errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

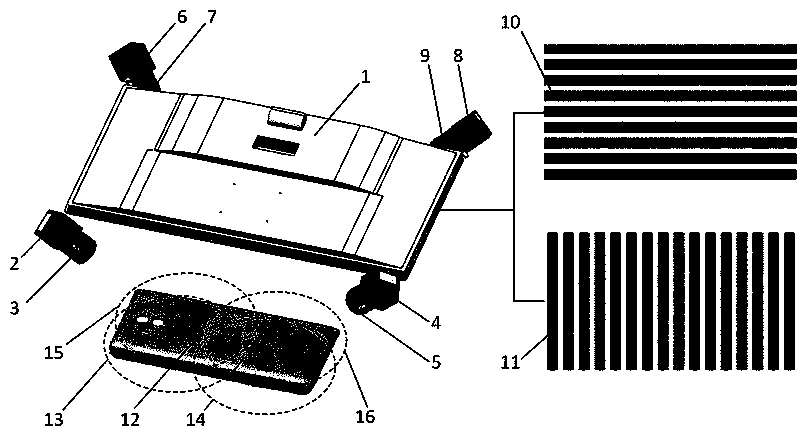

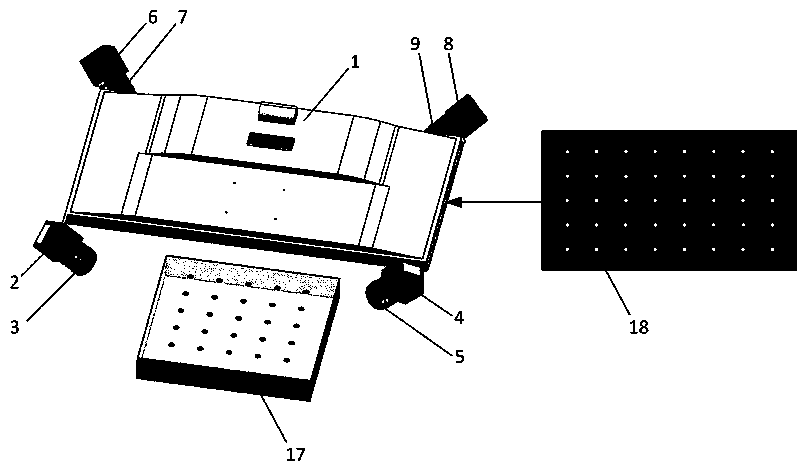

[0038] In this embodiment, four cameras are used to splice and measure the three-dimensional surface topography of the workpiece under test. Image 6 As shown, the reflective fringe three-dimensional surface measurement method based on multi-field stitching, the measurement steps are:

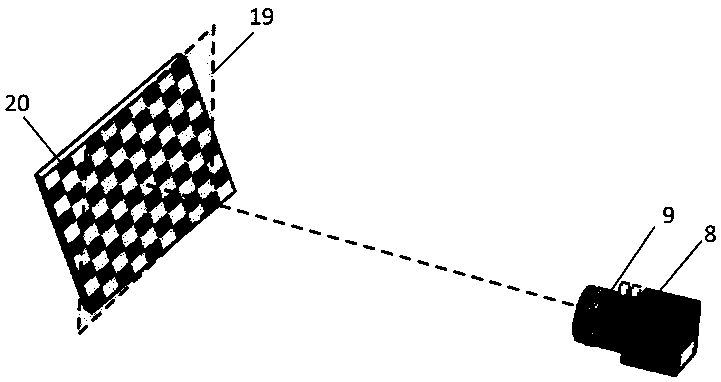

[0039] (a) Mount each camera (including No. 1 camera 2, No. 2 camera 4, No. 3 camera 6 and No. 4 camera 36) with a camera lens (including No. 1 camera lens 3, No. camera lens 7 and camera lens 4 37). All cameras are known to have a pixel size of 4.8 µm. If the focal length and distortion of the installed camera lenses are unknown, the focal length and distortion of the four camera lenses are first calibrated; if known, the pre-calibrated focal length and distortion can be used. In this embodiment, we first calibrate the focal length and distortion of the four camera lenses using checkerboard calibration boards. as attached image 3 As shown, in the calibration process, the checkerboard cali...

Embodiment 2

[0048] Different from Example 1, after obtaining the normal vector matrix ( Mx m , My m ) and synthesize them directly to obtain the normal vector matrix ( Mx , My ). During the compositing process, the average value of the normal vectors measured by multiple cameras is used when the overlapping parts are composited, and the normal vector value measured by a single camera is used when the non-overlapping parts are composited. Then the normal vector matrix ( Mx , My ) to perform a gradient integral operation to obtain the overall three-dimensional topography of the surface of the workpiece 12 under test. in, m =1,2,3,4.

Embodiment 3

[0050] Different from Example 1, in order to improve the three-dimensional shape in its step (h) S 1 , S 2 , S 3 with S 4 The synthesis accuracy of the 3D shape is corrected by the feature matching algorithm before the synthesis of the 3D shape S 1 , S 2 , S 3 with S 4 The small displacement and angle difference between them can contain the small displacement and angle difference in the three-dimensional surface shape measurement results of each part introduced by the calibration error of the principal point coordinates of the camera lens and the optical axis direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com