Electrical equipment and rapid soft start control method thereof

An electric equipment and electric drive technology, applied in battery/fuel cell control devices, electric vehicles, current collectors, etc., can solve problems such as reducing battery charge and discharge current, poor user experience for vehicle users, and extra waiting time. , to achieve the effect of reducing the discharge current and smoothing the normal working mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] see Figure 7 , the present invention discloses an electric device, which includes: a battery module 20, a range extender 10, at least one electric drive mechanism 30, and a fast soft start control system.

[0048] The battery module 20 is connected to the range extender 10 and each electric driving mechanism 30 through the first switch 21 . The electric drive mechanism 30 can be various types of motors (such as traction motors), and can also be a hydraulic motor.

[0049] The range extender 10 includes a supercapacitor 11 , a second switch 13 , and an energy converter 12 , and the supercapacitor 11 is connected to the energy converter 12 through the second switch 13 .

[0050] The fast soft start control system includes a first switch control circuit, a second switch control circuit, a supercapacitor discharge control circuit, an electric drive mechanism feedback circuit, a supercapacitor voltage monitoring circuit, and a working mode control module.

[0051] The fir...

Embodiment 2

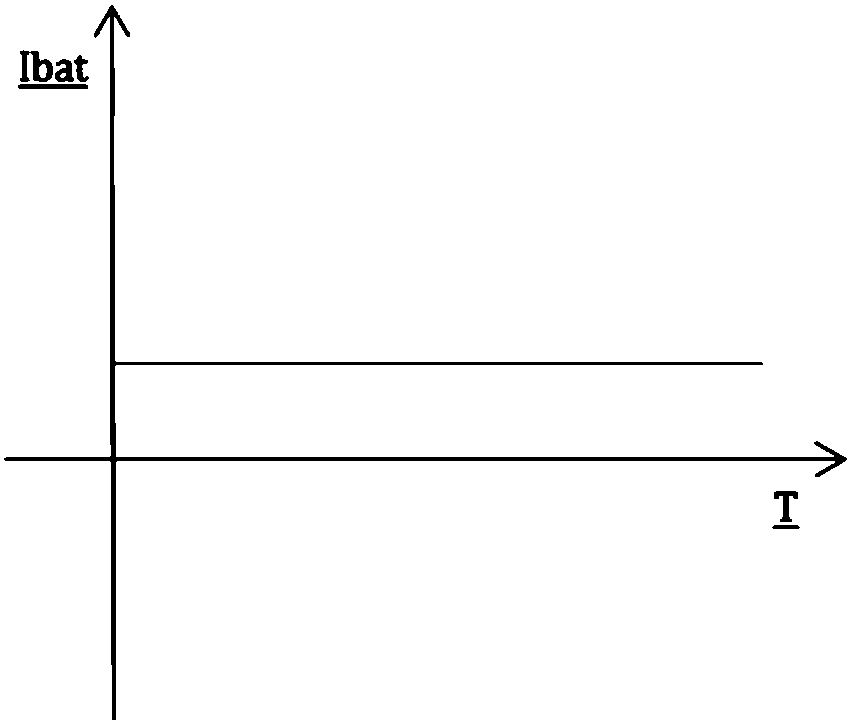

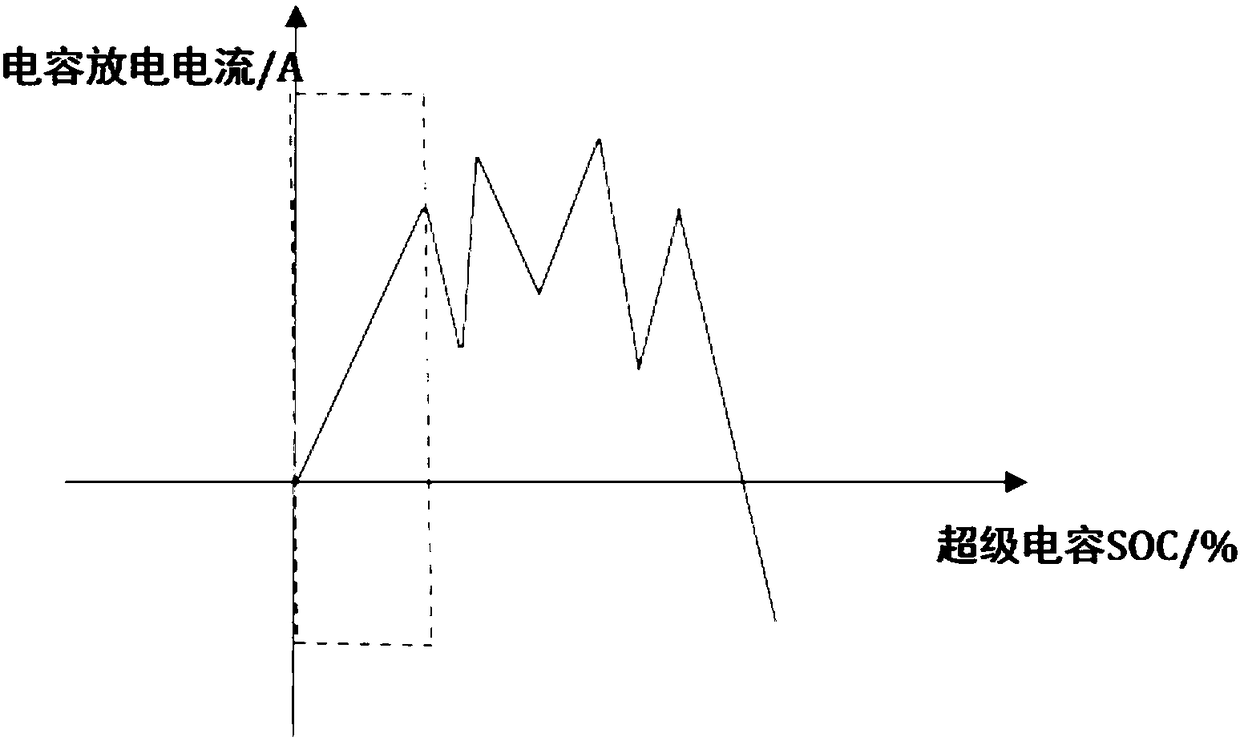

[0068] The difference between this embodiment and Embodiment 1 is that in this embodiment, the current of the battery is approximately expressed as Ibatreal=Iload-Iuc, so as to achieve the purpose of reducing the battery current, and the reduction effect is determined by the SOC of the current supercapacitor.

[0069] Among them, Ibatreal represents the actual battery current adjusted by the algorithm control, Iload represents the load current, and Iuc represents the current of the supercapacitor. Before the control of the algorithm of the present invention, Ibatreal=Iload, that is, Iuc=0.

Embodiment 3

[0071] In this embodiment, the fast soft start control method of the present invention includes:

[0072] (1) When the system is powered on, K1 and K2 are directly closed; the system can work normally without waiting for the supercapacitor to be precharged.

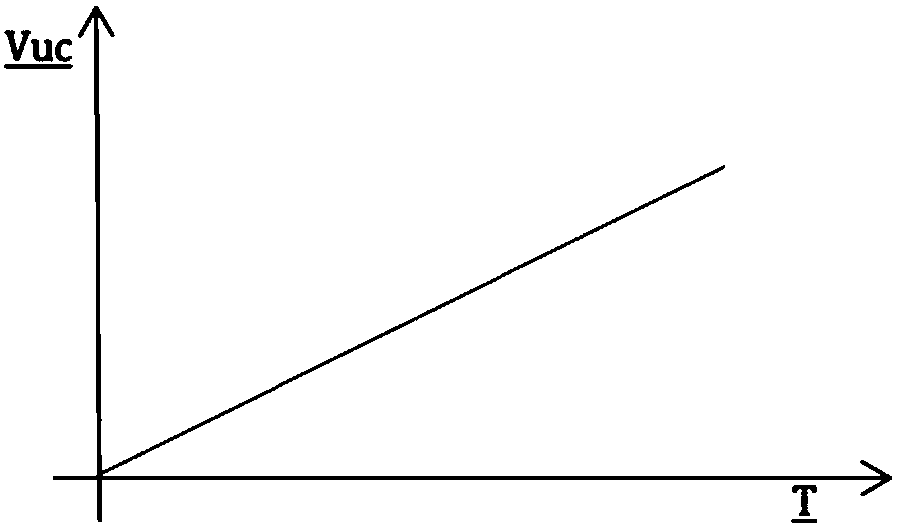

[0073] (2) Through the controlled discharge current of the supercapacitor, the peak current of the battery can be reduced, and at the same time, the energy of the motor can be used to feed back the supercapacitor for fast charging. Complete the precharging of the supercapacitor as soon as possible.

[0074] (3) When the capacitor reaches the pre-charge voltage, the system can smoothly enter the normal working mode.

[0075] After closing K1 and K2, the motor can work normally. For example, the line ② corresponds to the actual waveform of the motor’s normal working electromagnetic (such as Figure 4 , Figure 5 shown). At this time, it will be found that the battery current has a relatively large peak current. Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com