Low-temperature high-pressure resistant electric heater and its manufacturing method

A manufacturing method and high-voltage technology, applied in the direction of ohmic resistance heating parts, heating element shape, etc., can solve the problems of personal safety hazards, metal pipe walls are easy to be broken down or flicker, heating interruption, etc., and achieve insulation performance Reliable, eliminate personal safety hazards, and prevent heating interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Such as Figure 1-8 Shown, a kind of manufacturing method of low-temperature high-voltage resistant electric heater comprises the following steps:

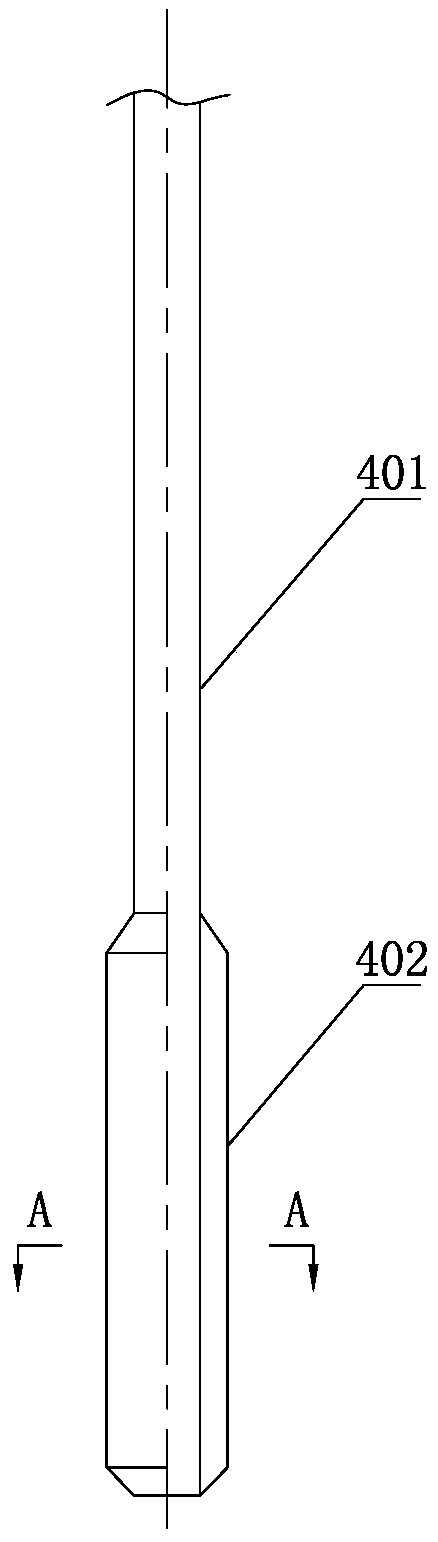

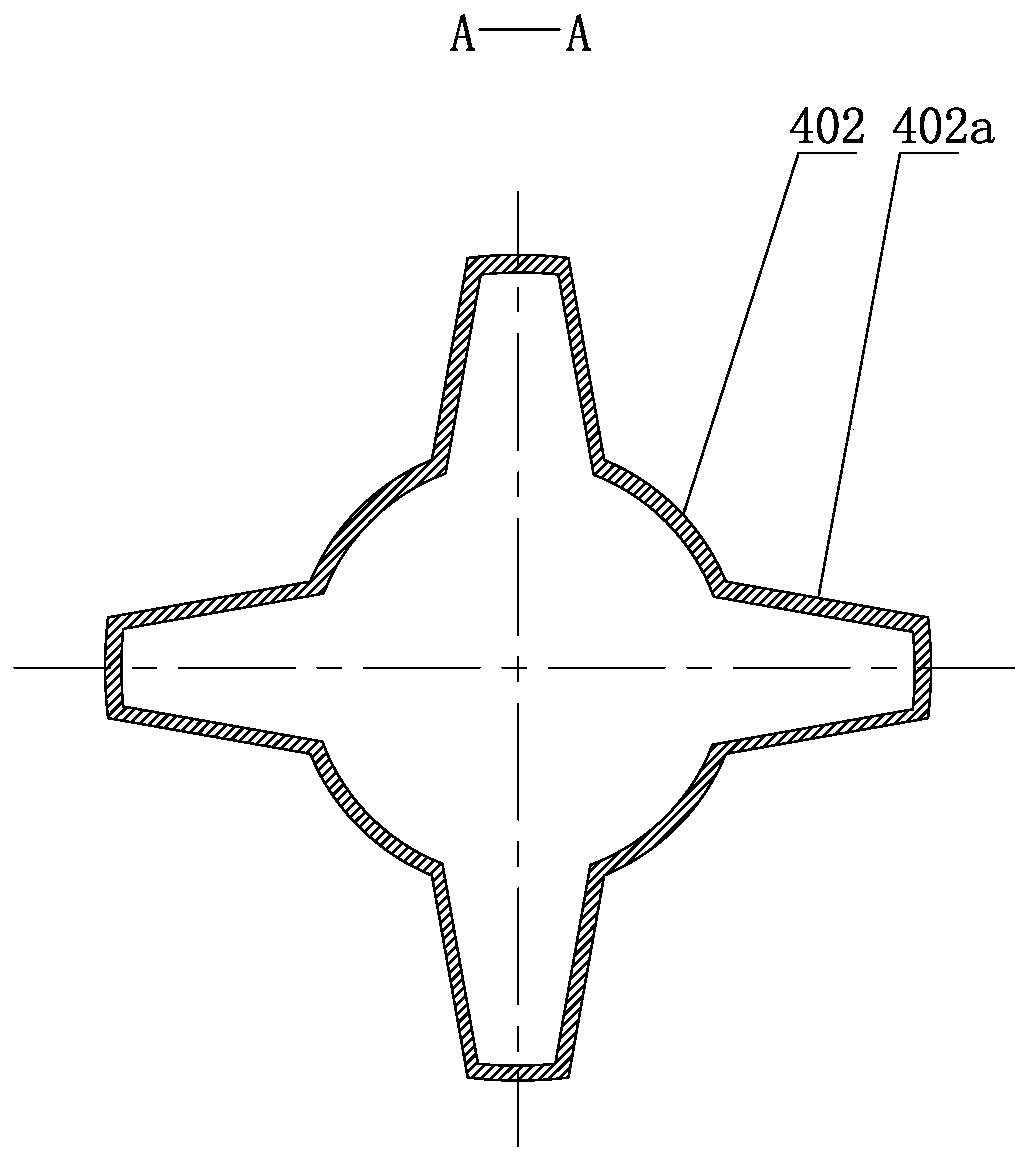

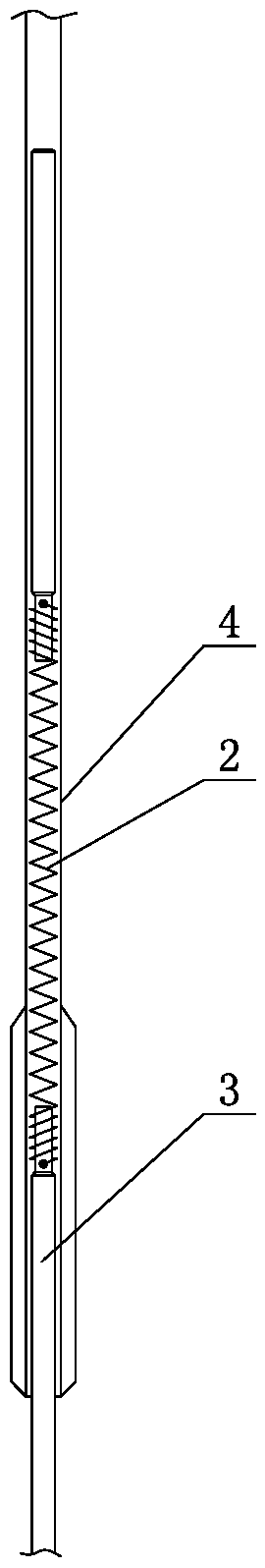

[0034] (1) Importing the medium-preserving tube: prepare electric heating tube 1, resistance wire 2, conductive lead-out rod 3 and medium-preserving tube 4 of corresponding length. Below the small-diameter section 401, the inner diameter of the middle-keeping tube 4 small-diameter section 401 matches the outer diameter of the resistance wire 2, and the outer diameter of the middle-keeping tube 4 support section 402 matches the inner diameter of the electric heating tube 1; The ends are respectively fixedly connected to a conductive lead-out rod 3, the resistance wire 2 is spiral, and the end of the conductive lead-out rod 3 close to the resistance wire 2 is provided with an external thread, the spiral-shaped resistance wire 2 is threadedly connected with the conductive lead-out rod 3, and fixed by spot welding , the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com