Bracket for joint repair

A joint and salt layer technology, applied in the field of prosthesis, can solve the problems of unreasonable structure of repairing stent, poor repair and regeneration effect, and unsatisfactory force transmission, and achieve excellent mechanical properties, good force transmission, strong resistance and so on. The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

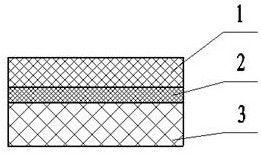

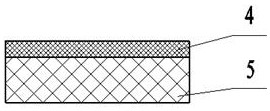

[0042] The scaffold for joint repair in this embodiment is composed of a porous polymer material layer 1 , a porous salt layer 2 and a porous metal material layer 3 in sequence from top to bottom. The porous polymer material layer 1 is a mixture of polylactic acid as the matrix and calcium polyphosphate short fibers, with a pore size of 3-10 μm, a porosity of 72%, and a thickness of 2.5 mm. The porous salt layer 2 is a porous inorganic salt layer, which uses porous hydroxyl Apatite, its pore size is 3μm-5μm, porosity is 40%, and thickness is 0.8mm; Porous metal material layer 3 is porous titanium, wherein porous titanium has two layers, see figure 2 , where the upper layer 4 (first layer) connected to the porous salt has a pore size of 50 μm-70 μm, a porosity of 35%, and a thickness of 2 mm, and the lower layer 5 (second layer) has a pore size of 100 μm-400 μm and a porosity of 85 %, the thickness is 4mm. The preparation method of the bracket for joint repair is as follows: ...

Embodiment 2

[0050] The scaffold for joint repair of this embodiment is similar to that of Embodiment 1, except that the porous metal material layer is a porous nickel-titanium alloy, the pore diameter of the first layer is 80 μm-100 μm, the pore diameter of the second layer is 800 μm-1000 μm, and the porous hydroxyl The pore diameter of the apatite is 5 μm-10 μm, and the porous polymer material layer adopts type II collagen and chitosan, and the pore diameter is 3-20 μm. The preparation method is similar to that of Example 1, except that when preparing the porous polymer material layer, a slurry made of type II collagen and chitosan is spread on the surface of the porous salt layer, and then freeze-dried to form a porous gel.

Embodiment 3

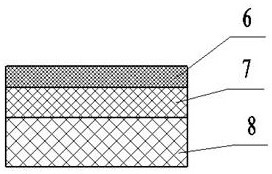

[0052] The scaffold for joint repair in this embodiment is composed of a porous polymer material layer, a porous salt layer and a porous metal material layer in sequence from top to bottom. The porous metal material layer is porous niobium, wherein the porous niobium is a gradient porous material, wherein the pore diameter of the surface close to the porous salt layer is 50 μm-80 μm, and the pore diameter of the distal surface of the porous niobium away from the porous salt layer is 100 μm-500 μm. The ratio is 78%, and the thickness is 7mm. The porous polymer material layer is divided into three layers. The bottom layer 8 close to the porous salt layer is made of type I collagen and hyaluronic acid, with a pore size of 10 μm-20 μm, a porosity of 60%, and a thickness of 1.5 mm. Collagen and hyaluronic acid, the pore size is 3μm-10μm, the porosity is 52%, the thickness is 1mm, the top layer 6 uses type I collagen, the maximum size of the pores is 5μm, the porosity is 45%, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com