Data acquisition method for syringe and syringe capable of automatically collecting scale data

A technology of data collection and automatic collection, which is applied in the field of medical devices, can solve the problems of inability to track and analyze patients' injection conditions, save or record dose scales, unfavorable promotion and application, etc., to achieve automatic collection and electronicization, with little difficulty in realization , easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

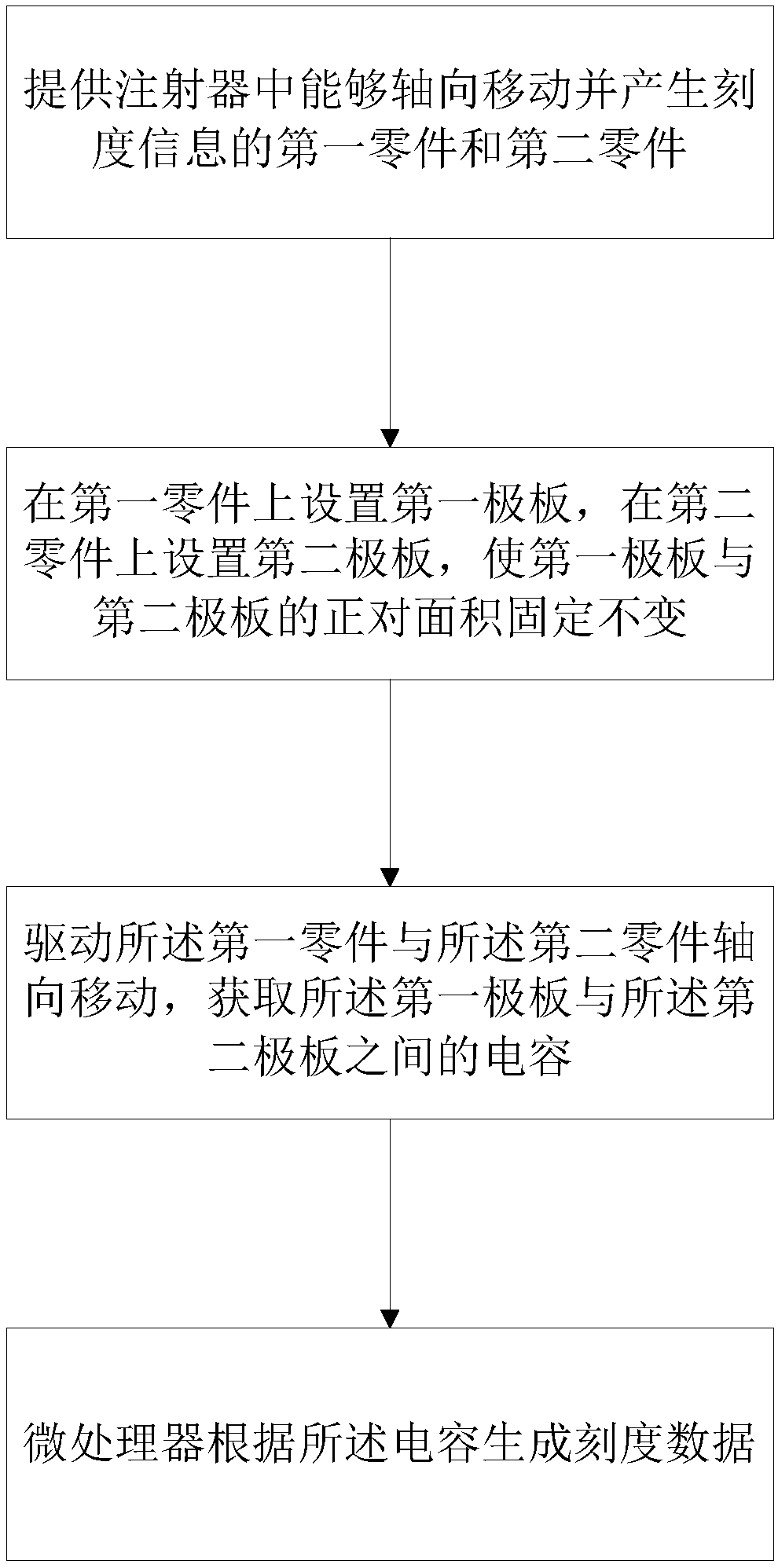

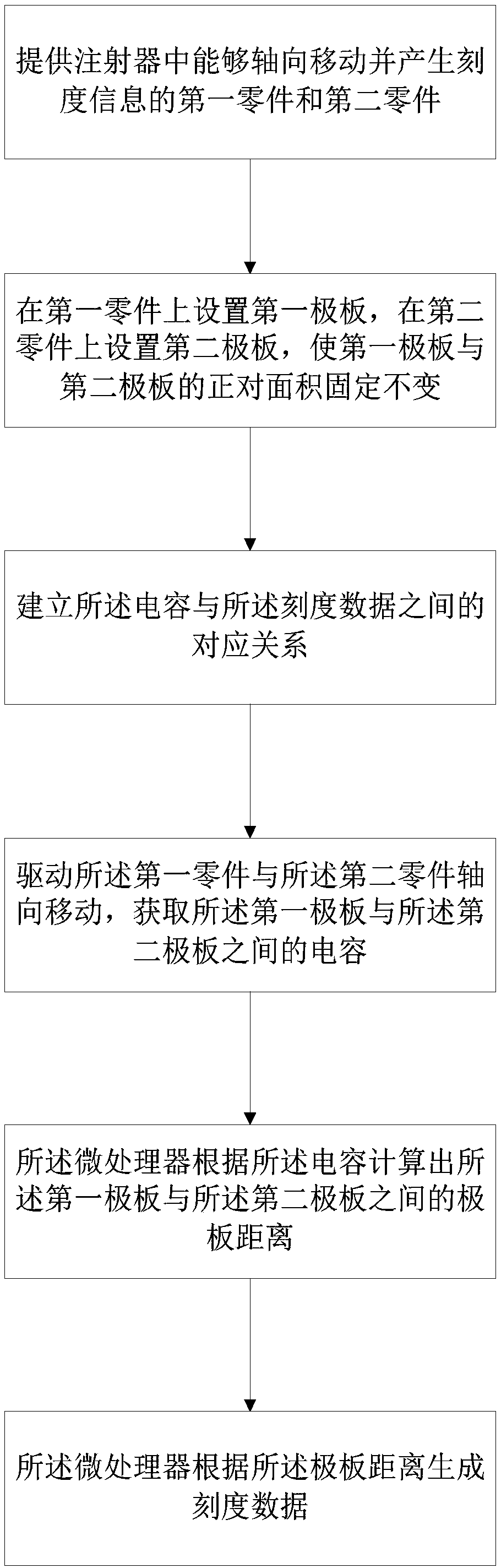

[0061] A method of collecting data for a syringe, such as figure 1 shown, including the following steps:

[0062] providing a first part and a second part of the syringe capable of moving axially and producing graduated information;

[0063] A first pole plate is arranged on the first part, and a second pole plate is arranged on the second part, so that the facing area of the first pole plate and the second pole plate is fixed;

[0064] drive the first part and the second part to move axially, and obtain the capacitance between the first pole plate and the second pole plate;

[0065] A microprocessor generates calibration data based on the capacitance.

[0066] Specifically, during the use of the syringe, the first part and the second part move axially relative to each other, so the distance between the first polar plate and the second polar plate will change , that is, the capacitance between the first pole plate and the second pole plate will change. This solution uses ...

Embodiment 2

[0076] The difference between this embodiment and Embodiment 1 is:

[0077] After the microprocessor generates scale data according to the capacitance, it also includes the following steps:

[0078] Judging whether the scale data is greater than the preset injection volume: if yes, sending out an alarm prompt.

[0079] In this embodiment, the alarm prompt is a sound prompt. In other embodiments, the alarm prompt is any one or any combination of sound prompts, indicator light prompts, screen prompts, smell prompts, and vibration prompts.

[0080] Specifically, in the actual use process, the user may need to use a variety of different drugs, and the dosage of these drugs is different. If the user makes a mistake with different drugs, resulting in an excessive dosage of the drug, serious consequences will occur. , and even cause life-threatening. In this solution, by judging whether the scale data is greater than the preset injection volume, it is possible to avoid excessive d...

Embodiment 3

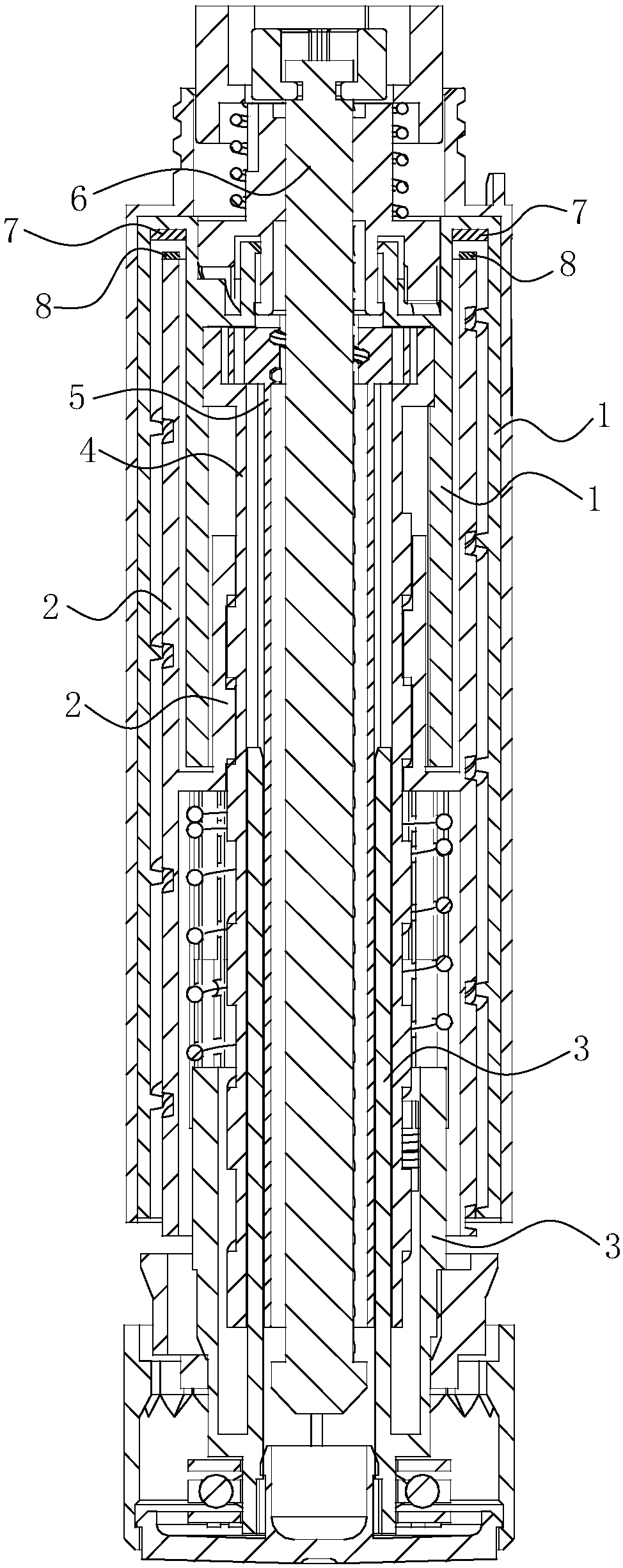

[0082] A syringe that automatically collects calibration data, such as image 3 and Figure 4 As shown, it includes a microprocessor, a first part and a second part, the first part and the second part produce axial movement during the dose scale adjustment process, and the first part is set There is a first pole plate 7, the second part is provided with a second pole plate 8, the area facing the first pole plate 7 and the second pole plate 8 is fixed, and the first pole plate The plate 7 and the second pole plate 8 are respectively electrically connected to the microprocessor, and the microprocessor detects the capacitance between the first pole plate 7 and the second pole plate 8 . The first pole plate 7 is a metal plate, and the second pole plate 8 is a metal plate.

[0083] Specifically, since the relative position of the first part and the second part can change with the change of the dose scale during the dose scale adjustment process, the relative position of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com