Grain drying and dedusting device

A drying device and grain technology, applied in the direction of drying and preserving seeds, separating solids, separating solids from solids with airflow, etc., can solve the problems of difficult removal of dust and low drying efficiency, and achieve good dust removal effect , high utilization rate of heat energy, improvement of efficiency and the effect of utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

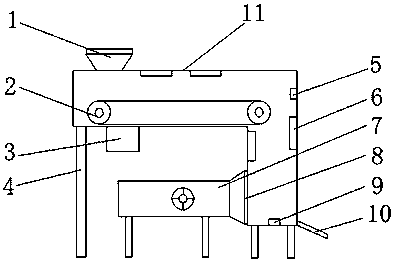

[0018] A grain drying device, comprising a feeding funnel 1, a conveyor belt 2 is arranged below the feeding funnel 1, a heating device 6 is arranged above and on the right side of the conveyor belt 2, a temperature sensor 5 is arranged on the inner wall of the casing 11, and the casing 11 is provided with a temperature sensor 5. A motor 3 is arranged under the body 11, a dust removal fan 7 is arranged on the right side of the casing 11, a filter screen 8 is arranged between the dust removal fan 7 and the casing, a humidity sensor 9 is arranged at the bottom of the casing 11, and the outlet is on the right side of the humidity sensor 9. The feed port 10 and the housing 11 are supported by the bracket 4 . An application method of a grain drying device is as follows: pour the grain to be dried from the feed hopper 1, the grain enters the conveyor belt 2 through the feed hopper 1, and the heating device 6 above and on the right side of the conveyor belt 2 works to turn the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com