Leaf mustard meat paste and making method thereof

A production method and mustard green technology, applied in the field of food processing, can solve the problems of inability to commercialize production, different mustard green taste effects, difficult quality assurance, etc., and achieve the effects of simple production, safety, no toxic and side effects, and easy portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

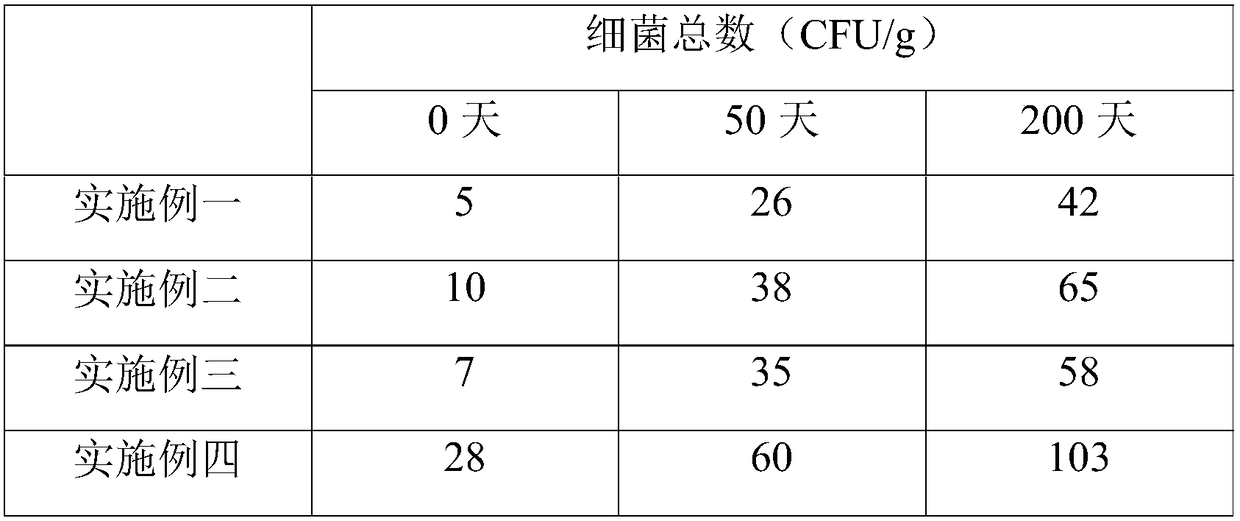

Examples

Embodiment 1

[0032] The present embodiment provides a kind of preparation method of mustard meat sauce, comprises the following steps:

[0033] S101: Slow down, wash and remove the mustard root hairs; then chop the mustard into 0.6cm particles; boil the water in the sandwich pot, put the chopped mustard in boiling water for 4 seconds and cool it down, then chop the mustard Drain excess water and set aside.

[0034] S102: Take a large plate of meat to slow down, and then use a sandwich pot to boil water to blanch the large plate of meat, and then use a pressure cooker to press the meat until it is half-cooked.

[0035] S103: Heat the edible oil, add seasoning, then add green onions and fry until golden brown, then stop the fire, and separate to obtain 500 g of cooking oil. Wherein, and in every kilogram of edible oil, the addition amount of Chinese prickly ash is 27g, the addition amount of aniseed is 33g, the addition amount of Chinese pepper is 8.5g, the addition amount of green onion is...

Embodiment 2

[0039] The present embodiment provides a kind of preparation method of mustard meat sauce, comprises the following steps:

[0040] S101: Slow down, wash and remove the mustard root hairs; then chop the mustard into 0.5cm particles; boil the water in the interlayer pot, put the chopped mustard in boiling water for 3 seconds and cool it down, then chop the mustard Drain excess water and set aside.

[0041] S102: Take a large plate of meat to slow down, and then use a sandwich pot to boil water to blanch the large plate of meat, and then use a pressure cooker to press the meat until it is half-cooked.

[0042] S103: Heat the edible oil, add seasoning, then add green onions and fry until golden brown, then stop the fire, and separate to obtain 500 g of cooking oil. Wherein, and in every kilogram of edible oil, the addition amount of Chinese prickly ash is 30g, the addition amount of aniseed is 30g, the addition amount of Chinese pepper is 6g, and the addition amount of green onio...

Embodiment 3

[0046] The present embodiment provides a kind of preparation method of mustard meat sauce, comprises the following steps:

[0047] S101: Slow down, wash and remove the mustard root hairs; then chop the mustard into 0.7cm particles; boil the water in the interlayer pot, put the chopped mustard in boiling water for 5 seconds and cool it down, then chop the mustard Drain excess water and set aside.

[0048] S102: Take a large plate of meat to slow down, and then use a sandwich pot to boil water to blanch the large plate of meat, and then use a pressure cooker to press the meat until it is half-cooked.

[0049] S103: Heat the edible oil, add seasoning, then add green onions and fry until golden brown, then stop the fire, and separate to obtain 500 g of cooking oil. Wherein, and in every kilogram of edible oil, the addition amount of Chinese prickly ash is 25g, the addition amount of aniseed is 35g, the addition amount of Chinese pepper is 10g, the addition amount of green onion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com