Antibacterial non-woven fabric

A technology of non-woven fabric and antibacterial layer, applied in the field of non-woven fabric manufacturing, can solve problems such as poor comfort, and achieve the effects of high comfort, good water absorption effect, and improved air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

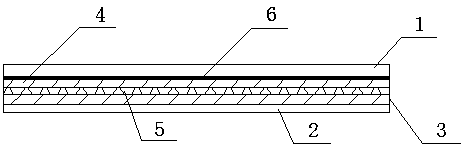

[0013] Such as figure 1 It is a structural schematic diagram of the present invention, an antibacterial non-woven fabric, comprising a liquid-leaking fabric layer 1, a liquid-tight bottom material layer 2 and an antibacterial layer 3 sandwiched in the middle, and the antibacterial layer 3 is composed of a double-layer non-woven fabric 4 Rolled and ironed with the resin layer 5, the resin layer 5 is laid in the middle of the double-layer non-woven fabric 4, the surface of the double-layer non-woven fabric 4 is plated with silver 6, and the double-layer non-woven fabric 4 and the resin layer 5 are processed by acupuncture. Fixedly connected, the outer surface of the double-layer non-woven fabric 4 is evenly distributed with air-permeable micropores, the resin layer 5 is made of acrylic material, and one side of the double-layer non-woven fabric 4 is plated with silver 6 .

[0014] By laying a layer of resin layer 5 between the double-layer non-woven fabrics 4, since each layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com