Improved paper shredder

A paper shredder and improved technology, applied in grain processing and other directions, can solve the problems of large occupied area, raised dust particles, complicated setting mode, etc., and achieve the effect of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

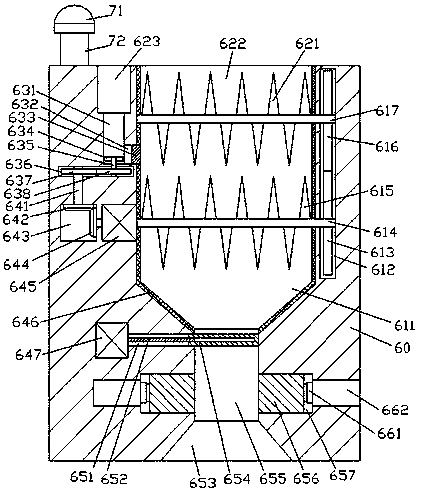

[0014] Such as Figure 1-2 As shown, an improved paper shredder of the present invention includes a pillar 50 and a machine body 60 fixedly arranged on the above. Cutting cavity 622, the inner wall of the body 60 on the right side of the cutting cavity 622 is extended with a first rotating groove 612 up and down, and a first rotating shaft 614 and a second rotating shaft 617 are respectively extending left and right in the cutting cavity 622 The extended tail ends on the right side of the first rotating shaft 614 and the second rotating shaft 617 protrude into the first rotating groove 612 and the tail ends are connected with the first rotating groove 612 in rotation, and the left side of the first rotating shaft 614 The extended tail end is connected with the first driver 645, the outer surface of the first driver is fixed in the inner wall on the left side of the cutting chamber 622, and the left side extension tail end of the second rotating shaft 617 is connected to the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com