Automatic grading device for energy saving and emission reducing automobile parts

A technology for auto parts, energy saving and emission reduction, applied in the field of automatic sorting devices, can solve the problems of high equipment maintenance costs, short service life of vulnerable parts, low efficiency, etc., reduce labor intensity and work fatigue, and ensure continuous The effect of orderly progress and saving the number of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

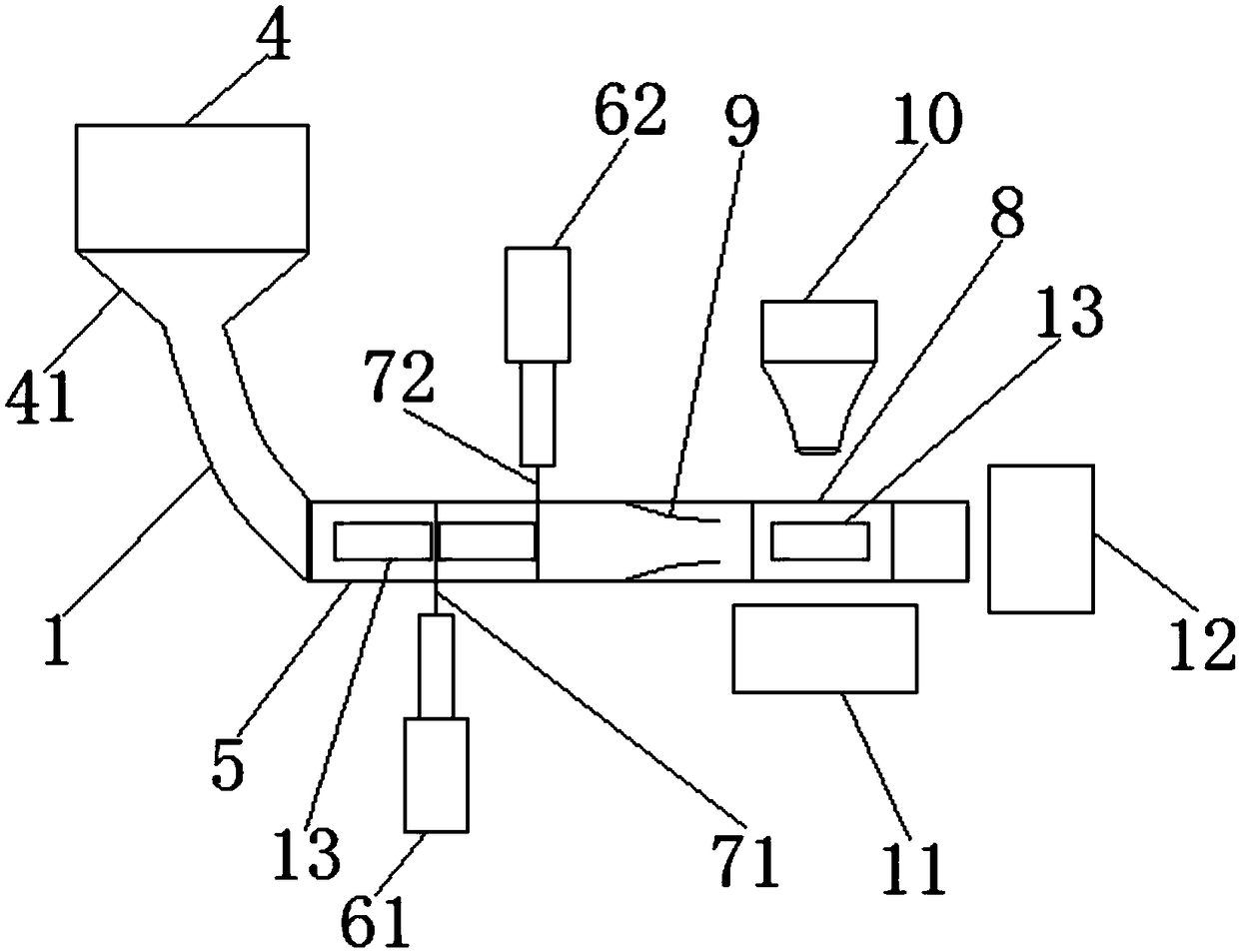

[0028] Such as figure 1 Shown is an automatic sorting device for energy-saving and emission-reducing auto parts. The device includes a vibrating feeding unit, a spacing adjustment unit, and a detection and sorting unit arranged in sequence along the moving direction of the product 13. The spacing adjustment unit includes a The conveying mechanism connected to the feeding unit and the baffle distance adjustment mechanism arranged at the beginning of the conveying mechanism, the detection and sorting unit includes a weighing detection mechanism and an air blowing sorting mechanism arranged at the end of the conveying mechanism, and the vibrating feeding unit conveys The products 13 in the conveying mechanism, after being adjusted by the baffle distance adjusting mechanism, enter the weighing detection mechanism one by one for weighing, and then are sorted and collected by the air blowing sorting mechanism.

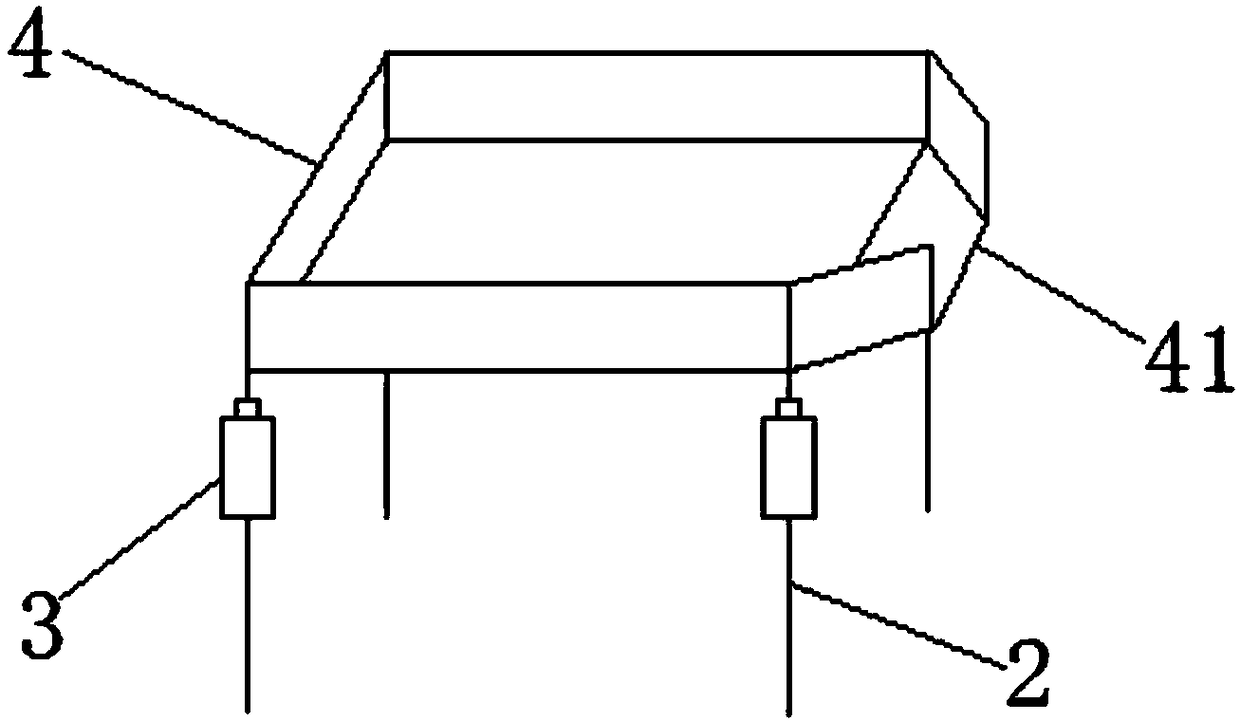

[0029]Wherein, the vibrating feeding unit includes a vibrating mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com